High-Efficiency Auto Lamp Assembly Line for Automotive Manufacturers: Boosting Production with Jinway Technology

In today’s competitive automotive industry, production efficiency and precision are more critical than ever. Automakers demand systems that can deliver consistent quality, speed, and flexibility — especially when it comes to delicate components like vehicle lighting. This is where Jinway Technology’s High-Efficiency Auto Lamp Assembly Line plays a pivotal role.

Advanced Automation for Modern Demands

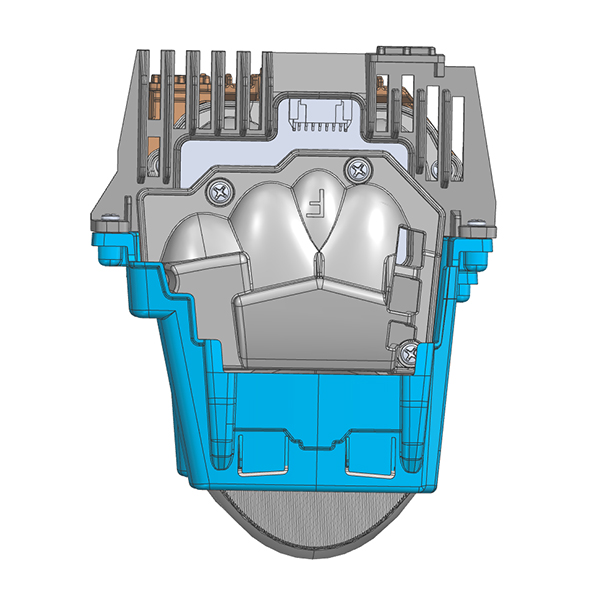

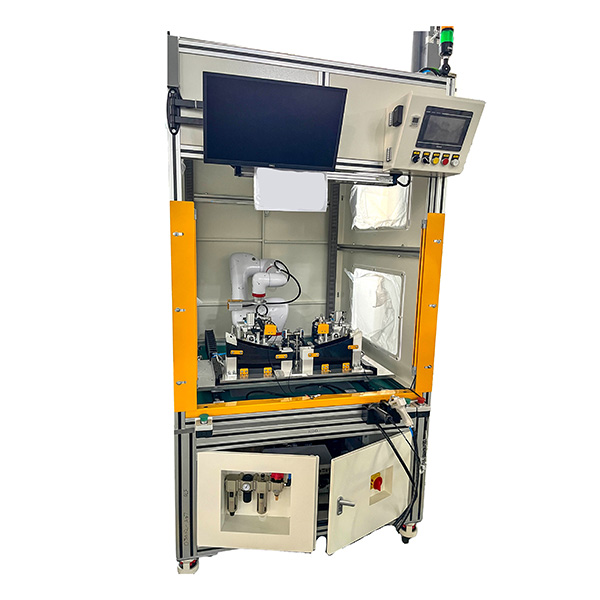

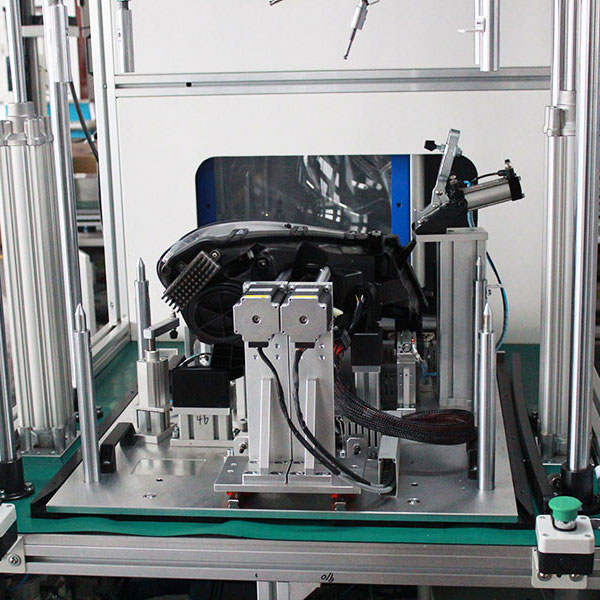

The Auto Lamp Assembly Line from Jinway Technology is engineered to meet the highest standards of modern automotive manufacturing. Designed for headlamps, taillights, and other vehicle lighting systems, this assembly line automates critical processes such as positioning, fastening, sealing, and quality inspection. With high-speed operation and exceptional precision, it significantly reduces production time while ensuring every product meets strict quality requirements.

By automating manual tasks, manufacturers can cut down on labor costs, minimize human error, and maintain a consistently high production output. Jinway’s systems are also modular, allowing manufacturers to customize the line according to specific production needs.

Key Features That Set It Apart

Jinway Technology’s Auto Lamp Assembly Line offers several important advantages:

High-Speed Production: Optimized for fast assembly without compromising accuracy, making it ideal for large-scale orders.

Stable and Reliable Performance: Robust mechanical design and intelligent control systems ensure stable operations even under heavy workloads.

Precision and Accuracy: Automated alignment and quality control processes guarantee perfect fitting and sealing of each lamp.

User-Friendly Operation: Touchscreen controls and smart monitoring systems simplify the entire operation process, making it easy for operators to manage.

Flexible Configuration: Whether producing simple designs or more complex LED and projector headlamps, the system can be tailored to meet specific product types.

Applications Across the Automotive Industry

This assembly line is ideal for automotive OEMs (Original Equipment Manufacturers), Tier 1 and Tier 2 suppliers, and specialist lamp producers. It supports a wide range of vehicle lamp types — from standard halogen headlamps to advanced LED systems — ensuring that manufacturers stay ahead of market trends.

By investing in Jinway Technology’s Auto Lamp Assembly Line, companies can improve production consistency, shorten delivery times, and meet the rising demands of automotive innovation.

Why Choose Jinway Technology?

Jinway Technology stands out not only for the quality of its products but also for its commitment to customer service. From initial consultation to post-sale support, Jinway provides:

☆ Expert guidance in selecting the right assembly solution

☆ Customized machine configuration based on customer requirements

☆ Reliable after-sales service and technical support

☆ Competitive pricing without compromising quality

Over the years, Jinway has built a strong reputation as a trusted partner for companies looking to modernize and upgrade their manufacturing processes.

Conclusion

In the fast-paced world of automotive manufacturing, precision, speed, and reliability are non-negotiable. Jinway Technology’s High-Efficiency Auto Lamp Assembly Line empowers manufacturers to achieve all three — boosting productivity, improving product quality, and staying competitive in a dynamic market.

For companies seeking to enhance their automotive lamp production capabilities, Jinway offers the smart choice for a brighter, more efficient future.