Engineering for Longevity: How We Build Low-Maintenance, High-Reliability Test Equipment

Introduction

In industries where precision and uptime are critical, testing equipment must be designed to perform flawlessly over long periods with minimal intervention. At Jinway Technology Co., Ltd., we understand that our customers rely on our systems not just for accuracy, but also for long-term stability, low maintenance, and dependable performance. That’s why we place engineering for longevity at the core of our product development philosophy. This article explores how we design and manufacture low-maintenance, high-reliability test equipment that stands up to the demands of modern industrial environments.

The Need for Long-Lasting Testing Solutions

In sectors such as automotive lighting, electronics, photometric measurement, and optical inspection, downtime can mean missed deadlines, reduced throughput, and costly service disruptions. Companies need test equipment that delivers consistently high performance over years—not just weeks or months. Equipment that frequently breaks down or requires regular calibration not only increases maintenance costs but also disrupts production flow.

That’s why longevity and low-maintenance operation are not optional—they are essential. And delivering this performance requires careful material selection, intelligent design, and rigorous validation processes.

Materials and Component Selection for Durability

The foundation of any long-lasting machine lies in the materials used. At Jinway, we begin our engineering process by selecting high-quality components that can endure industrial conditions such as temperature changes, vibration, dust exposure, and continuous operation.

Our systems are built with:

Industrial-grade sensors and optics, tested for stability across wide environmental ranges.

Aluminum and stainless steel structures that resist corrosion and wear over time.

Reinforced connectors and cabling to prevent signal degradation or disconnection.

Fanless or sealed enclosures, where possible, to reduce points of failure from dust or moisture.

This careful component selection reduces wear-and-tear and ensures that the equipment functions reliably even under 24/7 operations.

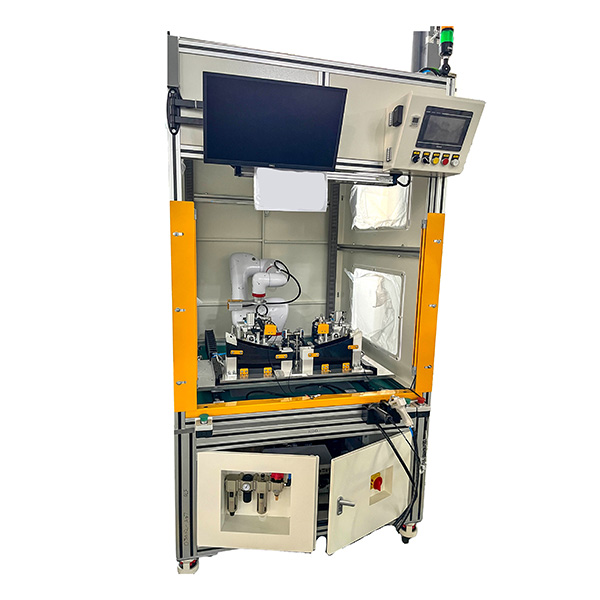

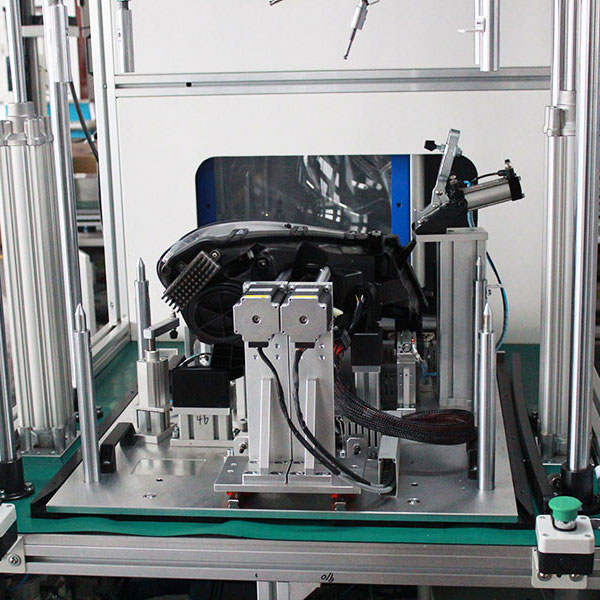

Smart Mechanical Design

Reliability isn’t just about tough materials—it’s also about intelligent engineering. Our mechanical and electrical systems are designed to minimize friction, reduce moving parts, and prevent overloading. Where motion is necessary—such as in positioning systems or scanning heads—we use:

Precision linear guides and bearings with long-life lubrication.

Closed-loop servo systems that auto-correct drift and maintain accuracy.

Vibration-damping mounts to reduce mechanical stress and improve measurement stability.

These choices extend the lifespan of key components and ensure long-term repeatability, even after years of continuous operation.

Calibration-Free and Self-Correcting Features

One of the primary pain points in maintaining test equipment is the need for regular calibration. Frequent recalibration increases downtime and labor costs while opening the door to human error. To address this, Jinway incorporates calibration-free sensors and self-correcting algorithms into many of our optical test systems.

For example, our photometric testing systems include internal references and auto-compensation routines that maintain accuracy without the need for constant human intervention. When recalibration is eventually needed, it is designed to be fast, intuitive, and infrequent—reducing the service burden on our customers.

Modular Design for Easy Maintenance

No matter how reliable a system is, wear and unexpected issues can still occur. That’s why we engineer our machines with modularity in mind. Subsystems are compartmentalized and easily accessible, making it quick and simple to swap out individual parts without dismantling the entire machine.

From removable vision modules to plug-and-play sensor arrays, this approach not only simplifies troubleshooting but also allows for future upgrades. A modular design ensures that even when change is required, it doesn’t result in prolonged downtime or costly overhauls.

Real-Time Diagnostics and Predictive Maintenance

Our systems also include built-in diagnostics that continuously monitor performance metrics and flag anomalies before they become failures. Users are alerted to component degradation, sensor drift, or environmental fluctuations in real time, allowing for predictive maintenance rather than reactive fixes.

Through integration with plant-level monitoring systems, our equipment can also contribute data to centralized maintenance dashboards—supporting smarter decision-making and resource planning.

Tested for the Long Haul

Reliability isn’t claimed—it’s proven. Every piece of test equipment developed at Jinway undergoes extensive life-cycle testing, environmental stress screening, and endurance validation. We simulate years of usage during the development process by exposing our systems to thermal cycling, vibration, humidity, and extended operational hours.

These tests ensure that when a machine is delivered to our client, it has already endured more than it’s likely to face in the field. This focus on upfront reliability testing greatly reduces field service events and ensures a longer equipment lifespan.

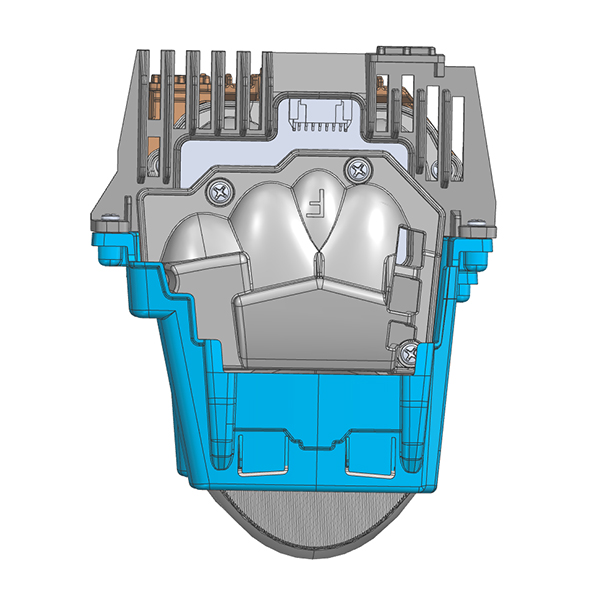

Case Study: Photometric Testing for Automotive OEMs

One of our long-term deployments involves photometric testing stations at an automotive OEM supplier, where systems have been running continuously for over five years with less than 1% downtime per year. These systems operate in a high-volume environment, inspecting thousands of headlamp units daily.

The machines’ longevity is due to a combination of robust optics, smart mechanical design, and predictive diagnostics—all of which were carefully engineered from the start to require minimal human maintenance. The result has been a measurable reduction in maintenance cost and significant improvement in throughput consistency.

Conclusion

At Jinway Technology Co., Ltd., we don’t just build machines—we build lasting value. Our focus on engineering for longevity and low-maintenance operation ensures that our clients can trust our test equipment to perform reliably, day after day, year after year. In an industry where reliability equates to profit, our systems are engineered not just to meet expectations—but to exceed them, over the long term.