Light as a Quality Standard: Why Photonics Is Becoming the Heart of Modern Manufacturing

In the rapidly evolving world of advanced manufacturing, light is no longer just a tool for illumination—it is becoming a fundamental standard for quality measurement. Photonics, the science of generating and harnessing light, is now deeply embedded in factory automation and testing systems. From precision inspections to automated defect detection, photonics-based technologies are redefining how industries approach accuracy, safety, and efficiency. At Jinway Technology Co., Ltd., we recognize that photonics is not just supporting modern production—it is shaping its future.

The Role of Photonics in Manufacturing

Photonics refers to the use of light particles (photons) for transmitting, detecting, and analyzing information. In manufacturing, photonics is applied through systems such as lasers, optical sensors, and imaging equipment. These tools enable precise measurements at microscopic levels, often with non-contact methods that preserve product integrity. As industries move toward high-value and high-complexity products, photonics ensures that every detail meets strict quality standards.

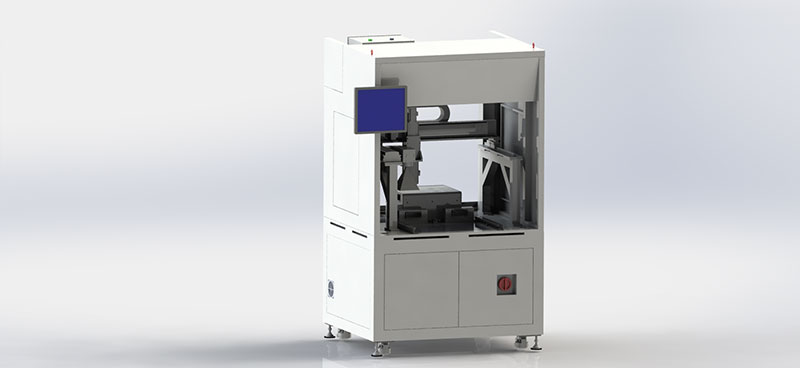

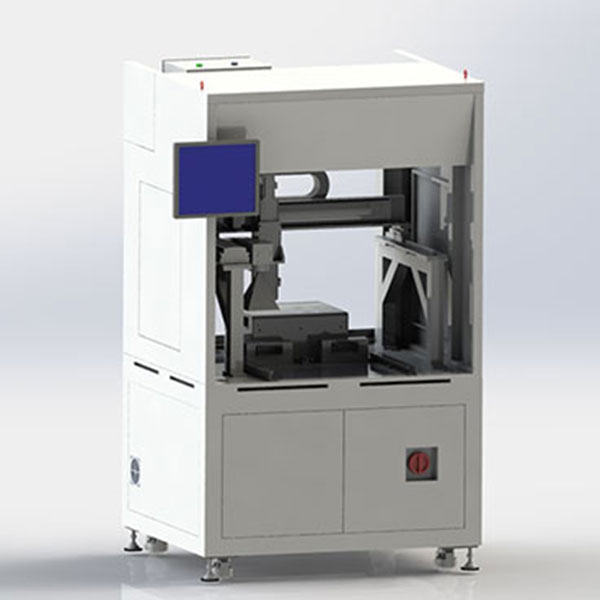

Light as a Non-Contact Inspector

One of the greatest advantages of photonics is its ability to measure without physical contact. Traditional inspection methods can be slow, labor-intensive, or prone to damaging delicate components. Photonics-based systems, such as optical testing machines, use light beams to measure dimensions, detect flaws, and analyze surfaces instantly. This makes them ideal for industries like automotive, electronics, and medical devices, where precision and reliability are non-negotiable.

Photonics in Automotive Lighting and Safety

Automotive manufacturing has become a key field for photonics applications. Photometric testing, which measures how light from headlamps and taillamps performs under real-world conditions, ensures compliance with strict global safety regulations. By applying photonics, manufacturers verify not only brightness but also beam distribution, glare control, and color fidelity. Without this level of accuracy, vehicle safety could be compromised. Photonics, therefore, plays a direct role in protecting lives on the road.

Enabling Zero-Defect Manufacturing

Photonics is also central to the pursuit of zero-defect manufacturing. Optical systems can detect defects invisible to the human eye or traditional inspection cameras, from micro-cracks to subtle misalignments. By integrating these systems into production lines, manufacturers catch errors in real time before products move downstream. This not only reduces costly recalls and warranty claims but also strengthens trust in brand quality.

Beyond Vision: The Power of Spectrometry

While vision-based optics are essential, spectrometry expands photonics into new dimensions by analyzing how materials interact with different wavelengths of light. For example, in coating processes, spectrometers verify thickness and uniformity at the molecular level. In electronics, they confirm solder quality and component integrity. By providing chemical and structural insights, spectrometry ensures that products perform reliably over time.

Driving Efficiency and Sustainability

Photonics also contributes to efficiency and environmental sustainability. Optical sensors reduce waste by ensuring materials are used correctly the first time. Automated optical testing minimizes the need for destructive testing methods, preserving valuable resources. In energy-conscious industries, photonics helps streamline processes while lowering overall carbon footprints—demonstrating that higher quality can align with greener manufacturing practices.

Integration with AI and Smart Factories

The future of photonics lies in its integration with artificial intelligence and smart manufacturing systems. AI-driven algorithms can process optical data faster than humans, recognizing patterns and predicting failures before they occur. When combined with digital twins and real-time analytics, photonics provides manufacturers with a powerful decision-making tool that improves both performance and resilience across production lines.

Applications Across Industries

Beyond automotive, photonics is shaping industries as diverse as aerospace, semiconductors, pharmaceuticals, and renewable energy. In aerospace, laser-based systems verify structural integrity at extreme tolerances. In semiconductors, photonics ensures nanometer-level precision. In pharmaceuticals, it confirms dosage and purity without opening containers. This cross-industry versatility highlights why light is becoming the universal language of quality in modern production.

Conclusion

Photonics is no longer just an enabling technology—it is becoming the heart of modern manufacturing. By using light as a universal quality standard, industries achieve greater accuracy, efficiency, and sustainability. From automotive lighting safety to high-precision assembly lines, photonics ensures that products meet the highest global standards. At Jinway Technology Co., Ltd., we see light not just as a tool, but as the foundation of manufacturing excellence. As factories embrace Industry 4.0 and beyond, photonics will remain the guiding standard for quality in every sector.