Closed-Loop Quality Control: How Automated Optical Testing Prevents Production Drift

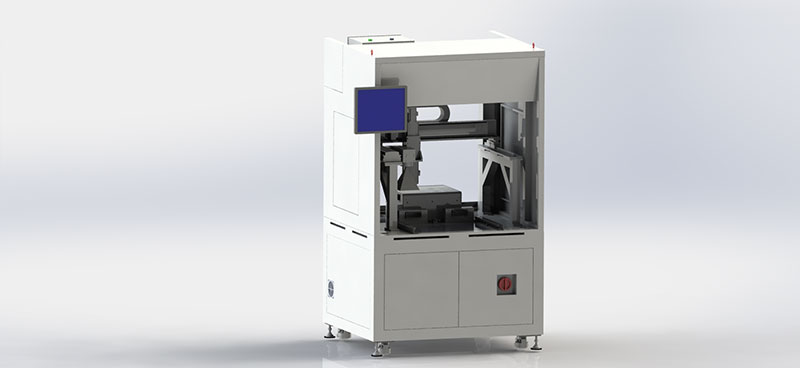

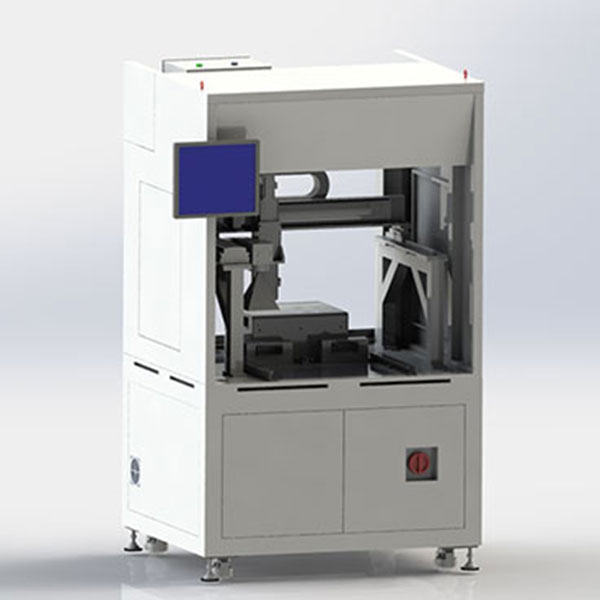

In modern manufacturing, consistency is just as important as innovation. Factories can produce thousands or even millions of identical components, but maintaining uniform quality throughout long production runs is a constant challenge. Even the smallest variation can lead to costly rework, warranty claims, or safety concerns. Closed-loop quality control—powered by automated optical testing—has emerged as a powerful solution to these challenges. At Jinway Technology Co., Ltd., we design advanced testing systems that integrate real-time feedback loops, ensuring that every product meets the highest standards without drifting from specifications.

Production drift occurs when small changes in machines, materials, or environmental conditions gradually push products away from their intended specifications. For example, slight wear in tooling, variations in raw material properties, or temperature fluctuations on the factory floor can introduce inconsistencies over time. While these shifts may be nearly invisible at first, their cumulative effect can compromise product quality and lead to defective output if not corrected quickly.

Closed-loop quality control refers to a system where inspection results are immediately fed back into the production process for automatic adjustment. Instead of identifying problems only after production is complete, closed-loop systems detect deviations in real time and correct them instantly. This continuous monitoring and correction process prevents defects from multiplying and ensures that every product meets the required specifications.

Automated optical testing is at the heart of effective closed-loop systems. By using high-resolution cameras, photometric sensors, and advanced imaging algorithms, optical systems can measure dimensions, shapes, and light performance with unmatched precision. Unlike manual inspection, which is slow and prone to human error, optical testing provides objective, repeatable, and accurate results at production-line speeds.

When integrated into manufacturing lines, optical testing machines continuously evaluate each component as it passes through. If a measurement drifts beyond tolerance, the system immediately sends feedback to adjust machine parameters—such as alignment, cutting angles, or assembly pressure. This closed-loop mechanism ensures that errors are corrected on the spot, preventing defective parts from advancing downstream or reaching customers.

Closed-loop quality control powered by optical testing offers several critical benefits:

Consistency: Every product maintains the same high standard, even across long production runs.

Efficiency: Early detection and correction reduce waste, rework, and downtime.

Cost Savings: By preventing production drift, manufacturers avoid costly recalls and warranty claims.

Compliance: Automated records provide traceable data for meeting regulatory and industry standards.

Scalability: Systems can handle high-volume production without sacrificing accuracy.

In the automotive industry, optical testing ensures that lighting systems, reflectors, and assemblies meet strict global safety standards. Even slight deviations in beam angles or brightness can have serious consequences on the road. Beyond automotive, industries such as electronics, aerospace, and medical devices also rely on closed-loop optical testing to maintain precision in highly regulated environments.

Another advantage of closed-loop systems is the wealth of data they generate. Each inspection adds to a detailed database of production quality, enabling manufacturers to identify long-term trends, predict equipment wear, and optimize processes. This data-driven approach transforms quality control from a defensive measure into a proactive tool for continuous improvement.

As factories continue to adopt Industry 4.0 technologies, closed-loop quality control will only grow in importance. The integration of artificial intelligence, machine learning, and digital twins will make feedback loops smarter and more adaptive. Optical systems will not only detect deviations but also predict potential failures before they occur, further enhancing reliability and efficiency.

Closed-loop quality control represents a major advancement in ensuring consistent, high-quality manufacturing. By combining automated optical testing with real-time feedback, manufacturers can prevent production drift and safeguard product performance. At Jinway Technology Co., Ltd., we are proud to deliver systems that embody these principles, helping industries achieve precision, reduce costs, and maintain their competitive edge. In a future where quality is non-negotiable, closed-loop optical systems are the key to keeping production on track.