Operator-Centric Design: Making Advanced Test Machines Easy to Use

As manufacturing systems become increasingly complex, the role of the human operator remains central. Even the most advanced test machines—equipped with optics, robotics, and artificial intelligence—ultimately depend on skilled operators for setup, monitoring, and decision-making. Designing these machines with an operator-centric focus ensures not only smooth workflows but also higher productivity, fewer errors, and greater job satisfaction. Operator-centric design bridges the gap between sophisticated technology and everyday usability. In many production environments, test equipment can be intimidating due to its complexity. Without intuitive interfaces or ergonomic layouts, operators may struggle to use machines effectively, leading to inefficiencies or mistakes. An operator-centric design philosophy prioritizes usability from the start, ensuring that machines serve as empowering tools rather than obstacles. By putting the operator at the center, manufacturers can achieve faster adoption, smoother operation, and reduced training time.

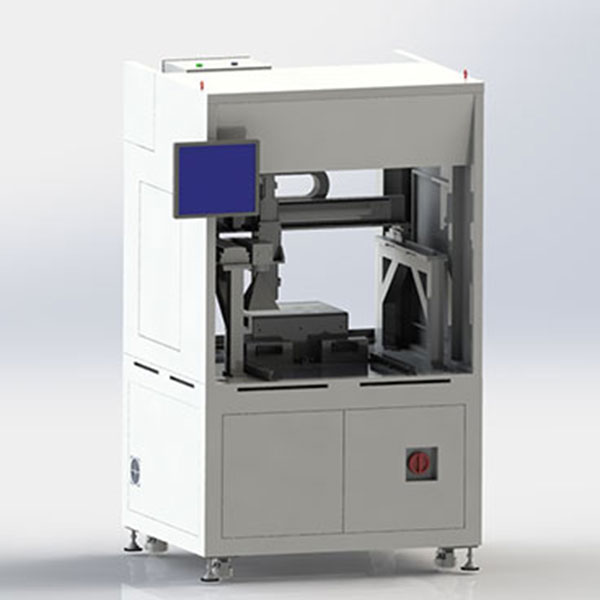

One of the key principles of operator-centric design is creating intuitive user interfaces. Touchscreen controls, clear icons, and straightforward navigation allow operators to manage advanced optical or mechanical tests without requiring extensive technical knowledge. Customizable dashboards can present only the most relevant data, minimizing distractions while providing deeper insights when needed. Simplicity in design reduces cognitive load, making advanced testing more accessible to all skill levels. Beyond software interfaces, the physical design of test machines plays a crucial role. Ergonomic considerations—such as adjustable workstations, accessible controls, and minimized repetitive movements—enhance operator comfort and safety. Machines built with thoughtful layouts reduce strain, prevent errors caused by awkward positioning, and allow operators to focus on precision rather than physical fatigue. Accessibility also means accommodating a diverse workforce, ensuring that controls and displays are usable by operators of different heights, strengths, and abilities.

Operator-centric machines integrate training directly into their systems. On-screen prompts, visual cues, and automated step-by-step guides provide real-time support during operation. Instead of relying on thick manuals or lengthy classroom sessions, operators learn as they work, building confidence and reducing downtime. This built-in training also helps new hires quickly adapt, easing the transition into advanced production environments. Advanced test machines are capable of assisting operators by detecting and correcting errors before they escalate. AI-driven systems can flag inconsistencies, suggest corrective actions, or automatically adjust parameters based on predefined quality standards. By supporting rather than replacing the operator, these systems turn the human-machine relationship into a collaborative partnership. This approach not only improves accuracy but also empowers operators to focus on higher-level tasks.

Operator-centric design also involves presenting complex data in a way that is easy to understand. Instead of overwhelming operators with raw numbers, test machines can visualize data trends, highlight anomalies, and provide actionable insights. With clear reporting tools, operators become active participants in quality control, capable of making informed decisions in real time. This transparency fosters a sense of ownership and accountability, strengthening overall production quality. When machines are designed with the operator in mind, trust naturally develops between human workers and automated systems. Operators who feel supported by their tools are more likely to embrace new technologies rather than resist them. This trust not only boosts efficiency but also paves the way for smoother adoption of future innovations, ensuring that technology upgrades enhance rather than disrupt daily operations.

Operator-centric design transforms advanced test machines from complex tools into user-friendly assets. By prioritizing intuitive interfaces, ergonomic layouts, built-in training, and smart assistance, manufacturers create systems that empower operators instead of overwhelming them. The result is higher productivity, fewer errors, and a more engaged workforce. In an era of rapid technological advancement, keeping operators at the heart of machine design ensures that innovation truly serves the people who use it.