How Modern Test Systems Collect and Analyze Failure Data to Continuously Refine Product and Equipment Design.

In the era of intelligent manufacturing, testing has evolved far beyond simple pass-or-fail evaluation. Modern test systems now serve as data-driven platforms that continuously collect, analyze, and interpret information from every production cycle. Among the most valuable outputs of these systems is failure data—the detailed insights generated whenever a product, component, or process does not meet required standards. By understanding and leveraging this data, manufacturers can refine both product design and equipment performance, driving ongoing improvement throughout the production ecosystem.

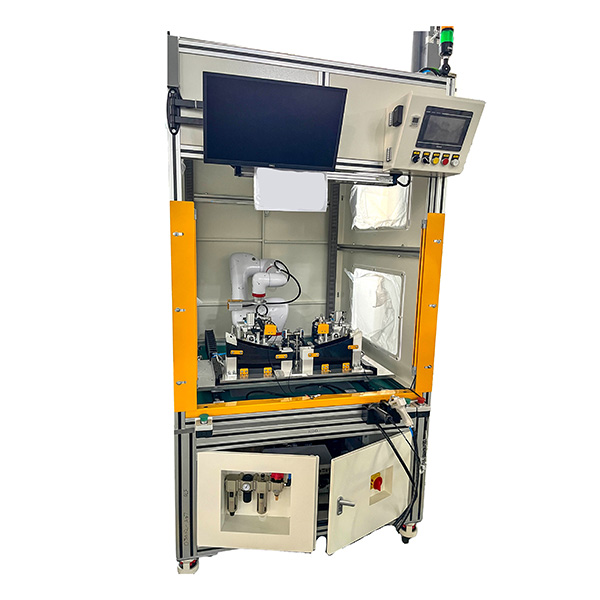

Traditional quality control once relied on random sampling and manual inspection, often addressing problems only after they occurred. However, as industries such as automotive, electronics, and aerospace move toward zero-defect manufacturing, reactive methods no longer suffice. Modern test systems are built with sensors, cameras, software, and connectivity that enable continuous data collection. Every defect, deviation, or performance variation is recorded in real time. This marks a significant shift from inspection to intelligent analysis, where every piece of failure data becomes a feedback signal for improvement.

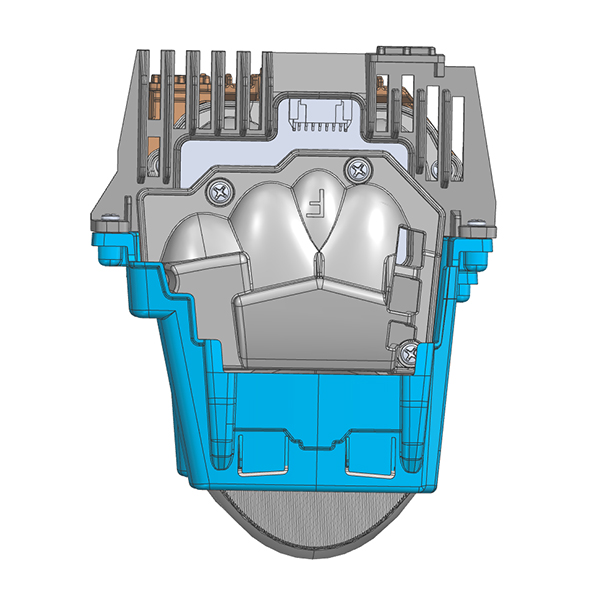

Failure data encompasses more than just the detection of non-conformities. It includes comprehensive information such as measurement trends, environmental conditions, component behaviors, test parameters, and timing of errors. For example, in photometric testing, a lighting unit might fail due to color shift, intensity deviation, or thermal instability. Each of these failures generates specific data points that can reveal patterns—such as a recurring issue tied to material properties, assembly techniques, or temperature variations. Analyzing this data helps engineers pinpoint the root cause, rather than merely flagging a problem.

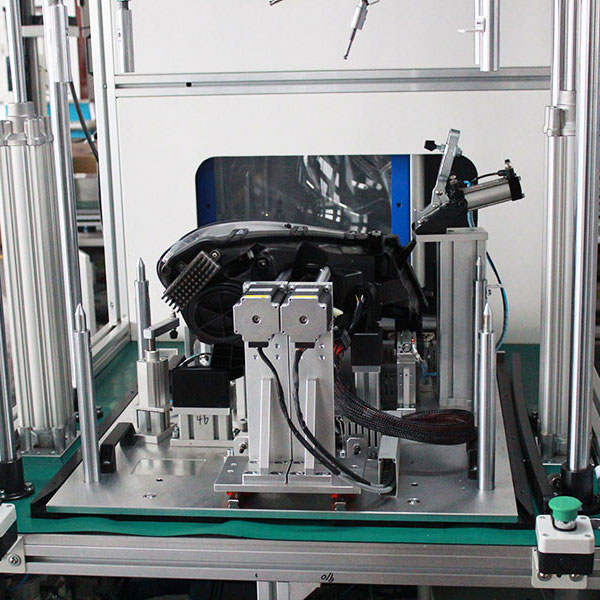

Modern test systems integrate advanced smart sensors and networked components that automatically record and transmit data. Vision systems, thermal cameras, and force sensors can detect even microscopic anomalies in real time. Each sensor contributes a piece of the puzzle—collecting optical, mechanical, or electrical feedback depending on the application. These systems are often connected to centralized databases or cloud servers, where data is organized and stored for analysis. The result is a unified testing ecosystem where information flows freely between testing stations, production lines, and engineering departments.

Once failure data is collected, the next step is transforming it into actionable insight. Advanced analytics platforms use algorithms, statistical tools, and artificial intelligence to detect trends that may not be visible to the human eye. For instance, if a specific defect occurs at a higher rate during certain times of day, it may indicate thermal drift in testing equipment. If component alignment errors increase after a certain production volume, it could point to wear in mechanical fixtures. Machine learning systems can automatically identify these relationships, allowing teams to address problems proactively before they escalate into major production issues.

Failure analysis doesn’t stop at the production floor—it loops back into the product design phase. Engineers use the data gathered from test systems to make targeted design improvements. For example, recurring brightness failures in LED modules might lead to changes in thermal management design or component layout. In the automotive sector, optical test data might drive revisions to headlamp housings, coatings, or reflector geometry to improve uniformity. This closed feedback loop between testing and design ensures that every generation of the product becomes more robust, efficient, and reliable.

Failure data also provides critical feedback about the testing equipment itself. Over time, data patterns can reveal calibration drift, sensor degradation, or mechanical instability within the test systems. Engineers can use this information to fine-tune equipment design—improving fixture rigidity, adjusting sensor positioning, or updating software algorithms. In some cases, manufacturers implement automated self-calibration routines that use stored failure data to correct deviations. This self-improving mechanism ensures that testing systems remain precise, reducing downtime and maintenance costs.

By integrating real-time monitoring and analytics, modern test systems enable predictive maintenance. Rather than reacting to sudden equipment failure, engineers can identify early warning signs—such as gradual data drift or repetitive minor faults—that indicate potential issues. Predictive algorithms then recommend maintenance actions before downtime occurs. This proactive approach keeps testing operations stable and prevents data corruption that could compromise quality evaluations. As a result, both equipment lifespan and data reliability are significantly enhanced.

Cloud-based platforms have revolutionized how failure data is managed and shared. Through secure connectivity, manufacturers can store vast amounts of test data, link it across multiple production facilities, and access it in real time from anywhere in the world. This data traceability ensures transparency and accountability across global supply chains. Engineers can track when, where, and why a failure occurred and compare it with data from other regions or product lines. Cloud integration also simplifies collaboration between testing teams, design engineers, and clients—shortening feedback cycles and accelerating innovation.

The ultimate goal of collecting and analyzing failure data is to create a culture of continuous improvement. Each test cycle becomes an opportunity to learn and refine. Statistical process control, root-cause analysis, and machine learning models collectively drive smarter decision-making across all levels of production. Manufacturers who fully embrace data-driven testing see measurable benefits—reduced defect rates, shorter development cycles, improved product durability, and optimized testing efficiency. Over time, this creates a self-sustaining ecosystem where every failure leads directly to progress.

Modern test systems have transformed from simple inspection tools into intelligent feedback engines that power innovation. By continuously collecting and analyzing failure data, manufacturers gain a deeper understanding of both product behavior and equipment performance. This synergy between data, design, and testing not only improves quality but also strengthens competitiveness in a market where precision and reliability are everything. As industries continue to move toward automation and AI integration, the ability to learn from every failure will define the next generation of smart, adaptive, and resilient manufacturing systems.