How UV Coating Enhances Durability and Aesthetics in Automotive Lighting

In the automotive industry, lighting systems have evolved from simple functional components into key design elements that define the character and safety of modern vehicles. Among the many innovations driving this evolution, UV coating technology stands out as a crucial process that not only enhances the visual appeal of automotive lighting but also extends its performance and lifespan. As a company specializing in OEM automotive lighting solutions, Jinway Technology Co., Ltd. has mastered the science and precision of UV coating to deliver superior-quality components that meet global standards of durability and aesthetics.

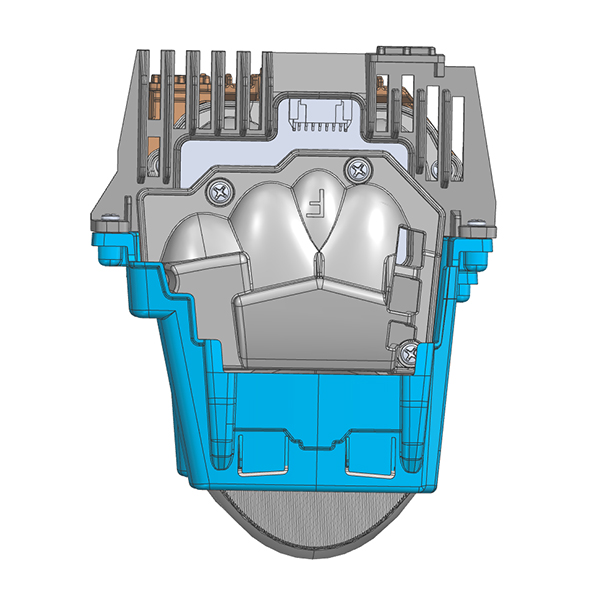

Automotive lighting components, such as headlamps and tail lamps, are constantly exposed to harsh environmental conditions. These include intense sunlight, heat, humidity, dust, and road debris—all of which can degrade plastic surfaces, cause yellowing, or reduce light clarity over time. UV coating acts as a protective barrier that shields these components from ultraviolet radiation and physical damage. It forms a thin but robust layer that resists oxidation and discoloration, ensuring the lamps retain their original brightness and clarity even after years of use. This protection is especially critical for polycarbonate lenses, which, while lightweight and impact-resistant, are prone to UV-induced degradation without adequate surface treatment.

Beyond its protective function, UV coating also plays an important role in the aesthetic refinement of automotive lighting. The coating enhances surface smoothness and gloss, giving headlamps and taillamps a premium appearance that complements vehicle design. It ensures uniform reflection and optical transparency, which are essential for achieving the crisp, clean lighting effect demanded by modern automotive brands. For designers, this finish is not merely cosmetic—it’s a statement of quality and innovation. A well-applied UV coating transforms ordinary plastic surfaces into elegant visual features that align with the car’s overall styling and identity.

The technology behind UV coating involves the application of a specialized coating material that is cured instantly using ultraviolet light. This process offers several key advantages. First, UV curing is extremely fast, allowing Jinway’s production lines to achieve high throughput while maintaining precision and consistency. Second, it produces a harder, more durable surface compared to traditional thermal curing methods. The resulting coating is scratch-resistant, chemical-resistant, and capable of withstanding extreme temperature changes. Third, UV coating is an environmentally friendly process, as it emits minimal volatile organic compounds (VOCs), aligning with the growing demand for sustainable manufacturing practices across the automotive industry.

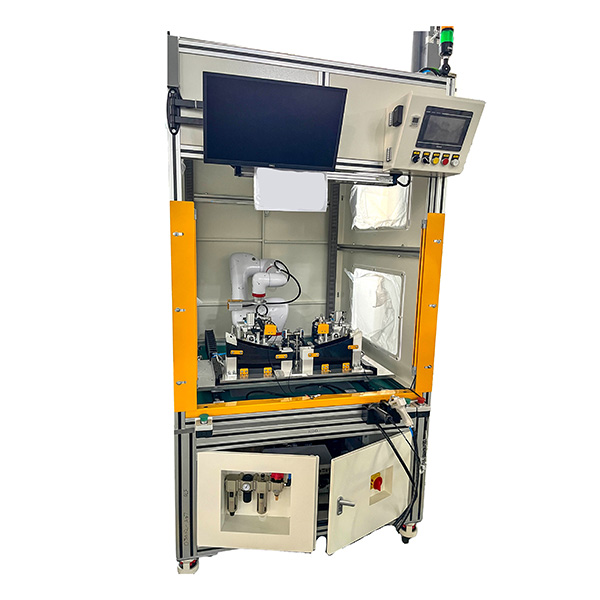

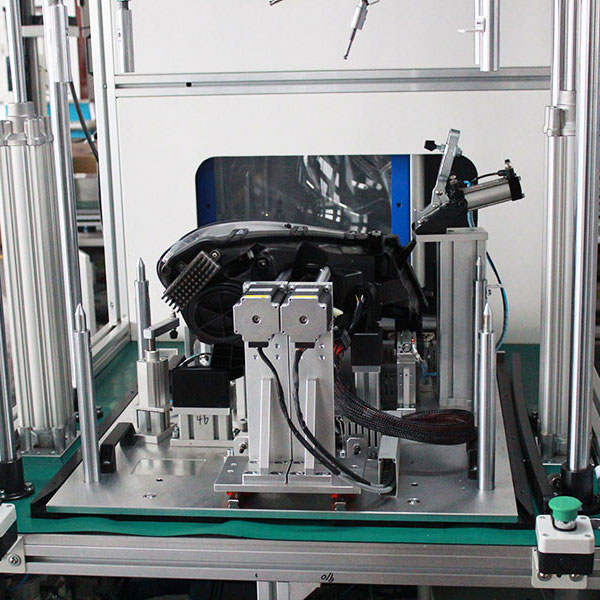

At Jinway Technology, UV coating lines are designed and built with advanced automation and control systems to ensure flawless coating application. In partnership with Wenton, Jinway provides complete UV coating and oven solutions that integrate seamlessly into automotive lighting production lines. Each process step—from surface cleaning and spraying to UV curing and final inspection—is precisely monitored to achieve consistent coating thickness, adhesion, and optical clarity. This integration not only improves production efficiency but also reduces human error and material waste, ensuring customers receive products that meet the strictest OEM quality requirements.

Another significant benefit of UV coating is its contribution to long-term cost efficiency. By preventing degradation, reducing maintenance needs, and extending the lifespan of lighting components, manufacturers and vehicle owners alike save on replacement and repair costs. Moreover, as automotive lighting increasingly incorporates complex shapes and advanced materials, UV coating provides the flexibility needed to maintain uniform coverage and high-quality finishes across diverse designs. As the global automotive industry continues to shift toward intelligent lighting systems and electric vehicle design, the demand for visually striking, durable, and sustainable components will continue to rise. Jinway Technology is at the forefront of this transformation, using its expertise in UV coating technology to set new benchmarks for quality and performance.

By combining technical precision, aesthetic excellence, and a commitment to innovation, Jinway ensures that every lighting component it produces not only shines brightly on the road but also stands the test of time. In an industry where appearance and reliability define brand reputation, UV coating remains one of the most vital processes in delivering both beauty and endurance to modern automotive lighting systems.