How Jinway Delivers End-to-End OEM Lighting Solutions Through Strong Partnerships

In today’s highly competitive automotive industry, lighting is no longer just a functional necessity—it is a defining element of vehicle identity, safety, and innovation. For OEM manufacturers, finding a reliable partner who can manage the entire production chain, from concept to final inspection, has become more important than ever. Jinway Technology Co., Ltd. has positioned itself as that trusted partner by delivering complete, end-to-end automotive lighting solutions supported by a powerful network of strategic partnerships. Founded in 2009 and focused on the OEM automotive lighting industry, Jinway specializes in tooling, assembly lines, UV coating lines, ovens, and related production equipment. Instead of working in isolation, Jinway has built strong alliances with leading technology specialists, including Wenton for UV coating lines and ovens, Cexcel for assembly lines, and DJ Mould for tooling solutions. This collaborative ecosystem allows Jinway to provide comprehensive, integrated solutions that cover every stage of the automotive lighting manufacturing process.

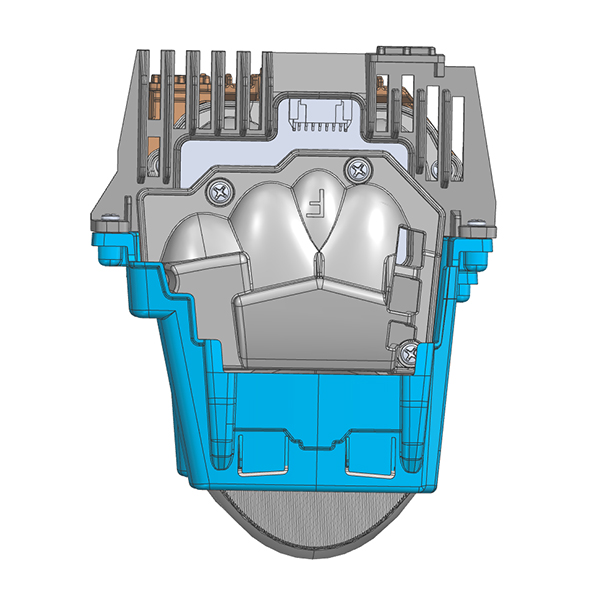

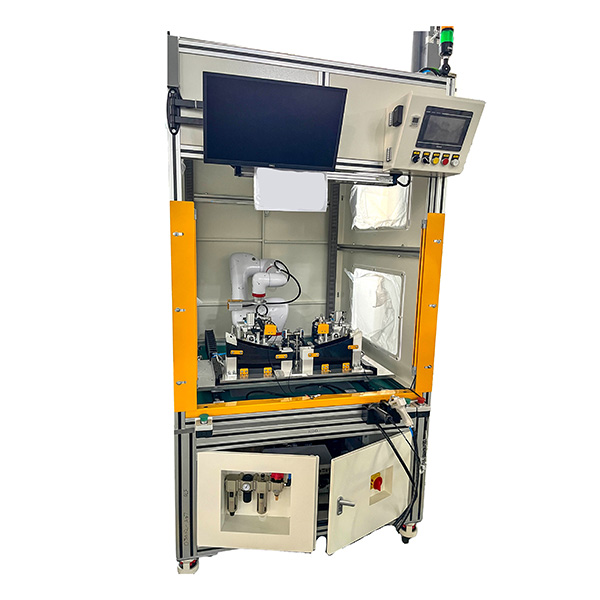

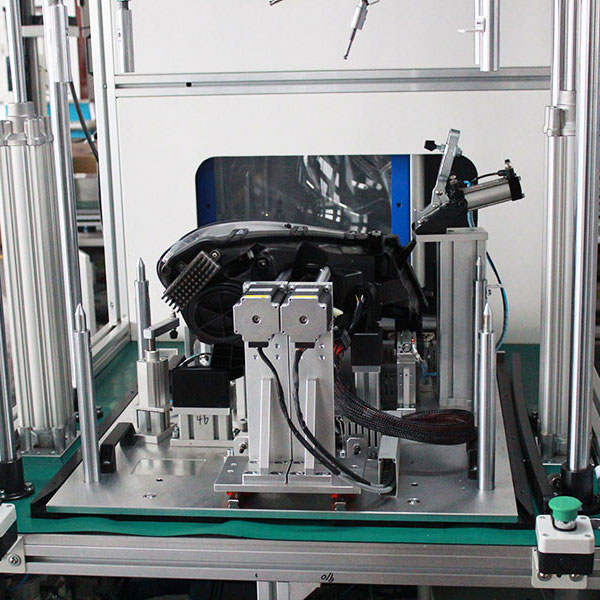

At the very beginning of a project, tooling plays a crucial role in shaping the quality and consistency of the final product. Through its partnership with DJ Mould, Jinway ensures that all molds are designed and manufactured with extreme precision. Accurate tooling guarantees that lamp housings, lenses, and internal components maintain perfect dimensional stability and surface quality. This is essential for achieving flawless assembly and optimal performance in the final lighting system. By taking part in the early design and development stages, Jinway also provides valuable suggestions for product optimization, helping OEM clients reduce future production risks and improve efficiency. Once the tooling is completed, the production process moves to assembly, where precision and consistency are key. In cooperation with Cexcel, Jinway delivers advanced auto lamp assembly lines that are designed for both high output and high accuracy. These lines combine automation with intelligent control systems to ensure that each component is assembled with the utmost precision. This not only increases productivity but also significantly reduces human error. As a result, OEM customers benefit from consistent quality, stable output, and a faster time-to-market—critical advantages in a fast-changing automotive landscape.

Surface treatment is another area where Jinway’s partnerships add tremendous value. Working with Wenton, Jinway provides state-of-the-art UV coating lines and ovens that protect automotive lighting components from environmental damage such as ultraviolet radiation, moisture, and heat. UV coating improves surface durability, enhances visual gloss, and prevents yellowing or fading over time. This is particularly important for polycarbonate lenses, which require strong protection to maintain clarity and brightness throughout their service life. By integrating advanced UV coating and anti-fog coating solutions, Jinway helps OEM manufacturers deliver lighting systems that remain both functional and visually appealing in the harshest conditions. Testing and quality control are integral parts of Jinway’s end-to-end solution strategy. The company provides equipment such as photometric optic test machines, air leakage detection systems, final inspection units, and engraving solutions. These systems ensure that every lighting unit meets strict international standards for brightness, beam pattern, sealing performance, and overall reliability. By integrating quality control directly into the production line, Jinway eliminates inconsistencies and ensures that only fully compliant products reach the customer.

What truly sets Jinway apart is the strength of its technical team. Comprised of experienced professionals and top industry talents, the team offers hands-on support throughout the entire project lifecycle. From design consultation and system planning to installation, training, and after-sales support, Jinway remains closely involved at every stage. This proactive approach allows the company to respond quickly to challenges, provide customized recommendations, and maintain strong, long-term relationships with its global clients. In addition to technical excellence, Jinway is guided by a clear and consistent principle: delivering high-quality products with short lead times and competitive pricing. This commitment has earned the company praise and trust from customers around the world. By optimizing workflows, streamlining processes, and enhancing coordination among its partner companies, Jinway continuously improves efficiency while maintaining exceptional quality standards.

As the automotive industry moves toward smarter, more integrated, and more sustainable lighting systems, the demand for full-chain solution providers continues to grow. Jinway’s unique partnership model enables it to meet this demand with confidence. By uniting expertise in tooling, assembly, coating, and testing under one coordinated framework, Jinway delivers not just individual machines or components, but complete, reliable, and future-ready lighting production solutions. Through strong partnerships, technical innovation, and an unwavering commitment to excellence, Jinway Technology Co., Ltd. continues to drive progress in the OEM automotive lighting industry—helping its customers illuminate the road ahead with clarity, safety, and style.