Smart Manufacturing in Automotive Lighting: Jinway’s Path Toward Industry 4.0

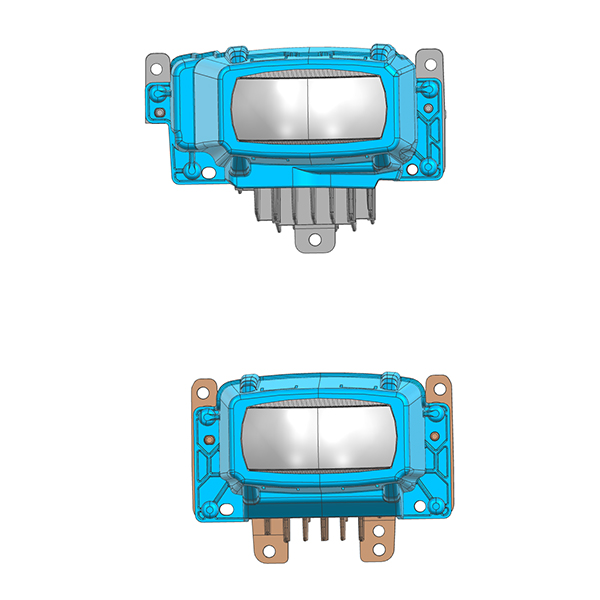

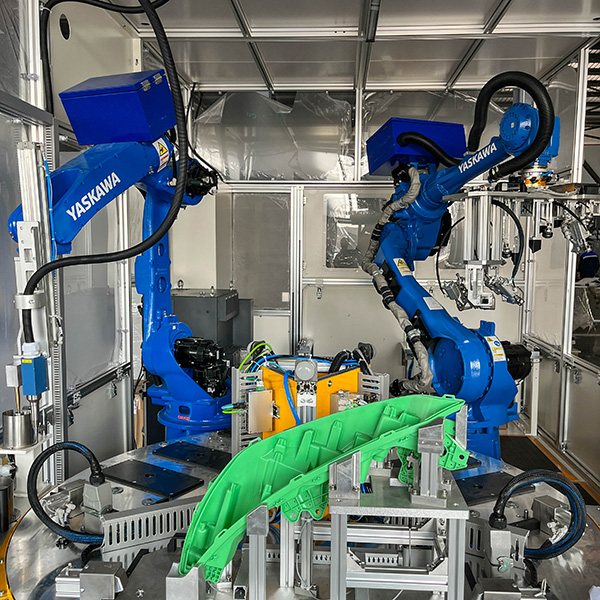

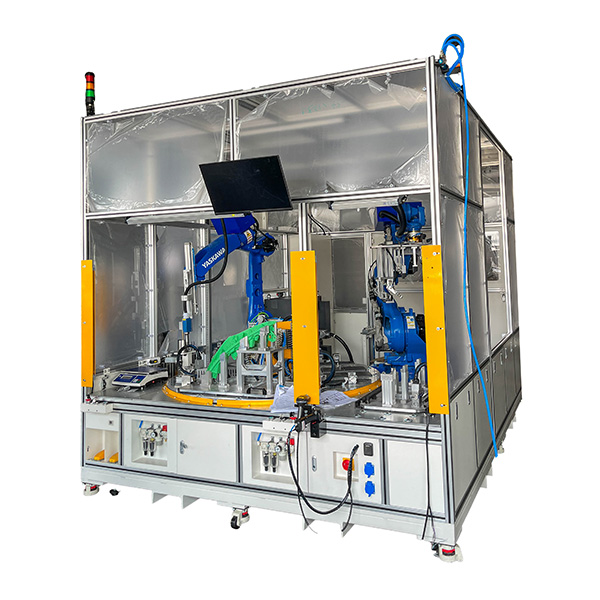

The automotive lighting industry is undergoing a profound transformation as manufacturers embrace digitalization, automation, and data-driven production. With increasing demands for precision, customization, and zero-defect quality, traditional manufacturing models are no longer sufficient. Smart manufacturing, driven by Industry 4.0 principles, has become the foundation for future competitiveness. Jinway Technology Co., Ltd. is actively advancing along this path, integrating intelligent systems across its automotive lighting production to deliver higher efficiency, consistent quality, and greater flexibility for global OEM customers. At the core of Jinway’s smart manufacturing strategy is automation. Modern automotive lighting components involve complex structures, advanced optics, and multiple surface treatments, all of which require extreme accuracy. Jinway’s automated assembly lines, developed in collaboration with Cexcel, ensure stable and repeatable processes that minimize human error. Robotic handling, precision positioning, and synchronized workstations allow for smooth production flow while maintaining tight tolerances across high-volume output.

Digital control and real-time monitoring play an equally important role. Jinway integrates intelligent sensors and control systems throughout its tooling, coating, and assembly processes. Parameters such as temperature, pressure, coating thickness, curing intensity, and assembly alignment are continuously monitored and adjusted automatically. This real-time feedback enables immediate corrective action, preventing deviations before they become defects and ensuring consistent product quality. Data connectivity is a defining feature of Industry 4.0, and Jinway has built a manufacturing environment where equipment, inspection systems, and management platforms are fully connected. Production data from photometric testing, air leakage inspection, and final quality checks are collected and analyzed centrally. By leveraging data analytics, Jinway identifies trends, predicts potential issues, and optimizes process efficiency. This proactive approach shifts quality control from reactive inspection to predictive prevention.

Surface treatment and coating processes have also been transformed through smart manufacturing. Jinway’s UV coating lines and ovens, developed with Wenton, are designed for intelligent operation and seamless integration into automated production systems. Precise control of curing parameters ensures superior surface durability, optical clarity, and environmental performance. Automated material handling and optimized curing cycles reduce energy consumption and material waste, supporting both productivity and sustainability goals. Traceability is another essential element of Jinway’s Industry 4.0 journey. Through engraving and digital identification systems, each lighting component is assigned a unique production record. From raw materials and processing parameters to testing results and final inspection data, every step is documented. This full traceability enhances accountability, simplifies quality audits, and allows for rapid root-cause analysis should any issue arise in the field.

Beyond technology, Jinway recognizes that smart manufacturing also depends on skilled people. The company invests in continuous training for its technical team, ensuring engineers and operators can effectively manage intelligent systems and interpret production data. Human expertise combined with automation allows Jinway to remain flexible, responsive, and innovative in a fast-changing market. As the automotive industry moves toward electric vehicles, intelligent lighting systems, and customized designs, the demand for agile and intelligent manufacturing will continue to grow. Jinway’s path toward Industry 4.0 positions the company as a forward-looking partner capable of supporting next-generation automotive lighting projects. By integrating automation, digital control, data intelligence, and human expertise, Jinway is not only upgrading its manufacturing processes but also redefining how quality, efficiency, and innovation are delivered in automotive lighting. Through smart manufacturing, Jinway continues to illuminate the future—driving precision, reliability, and technological leadership in the era of Industry 4.0.