How Photometric Testing Ensures Global Compliance for Automotive Lighting

In the automotive lighting industry, performance is not judged by appearance alone. Headlamps, tail lamps, and signal lights must meet strict photometric requirements to ensure safety, visibility, and regulatory compliance across different global markets. Photometric testing plays a critical role in verifying that automotive lighting products deliver the correct light distribution, intensity, and uniformity before they reach the road. Photometric testing refers to the precise measurement of light output characteristics, including luminous intensity, beam pattern, cutoff line, and glare control. These parameters directly affect how well a driver can see the road ahead and how safely other road users can perceive the vehicle. Even minor deviations in light distribution can result in reduced visibility, excessive glare, or regulatory rejection, making accurate testing essential in modern lighting production.

Global automotive markets operate under different regulatory frameworks. Standards such as ECE regulations in Europe, SAE and FMVSS standards in North America, and GB standards in China each define specific photometric requirements. While these regulations vary in detail, they all demand strict control over beam shape, brightness levels, and angular distribution. Photometric testing systems enable manufacturers to verify compliance with these diverse standards using precise measurement and data analysis, reducing the risk of failed certifications or costly redesigns. Advanced photometric optic test machines simulate real-world lighting conditions by measuring light performance across multiple angles and distances. These systems generate detailed light distribution maps that allow engineers to compare actual performance against regulatory benchmarks. Through this process, potential issues such as uneven illumination, insufficient brightness, or excessive glare can be identified and corrected early in the production cycle.

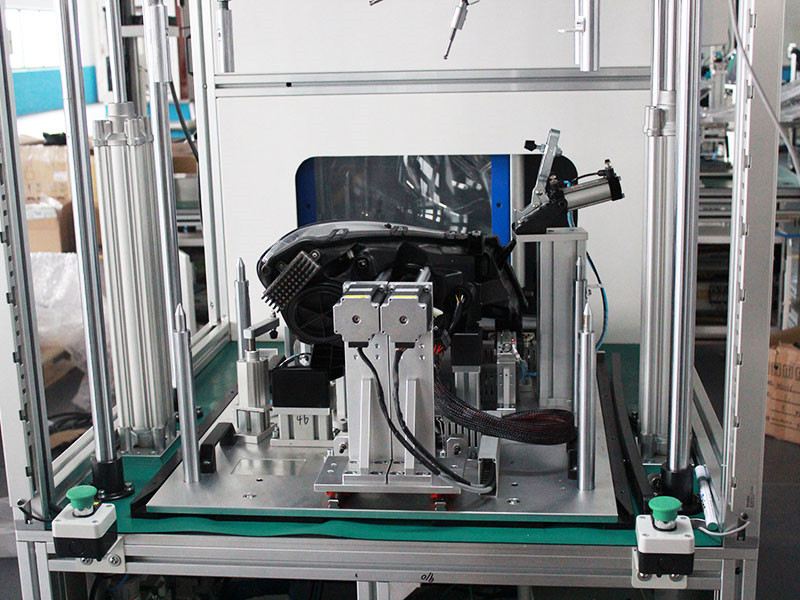

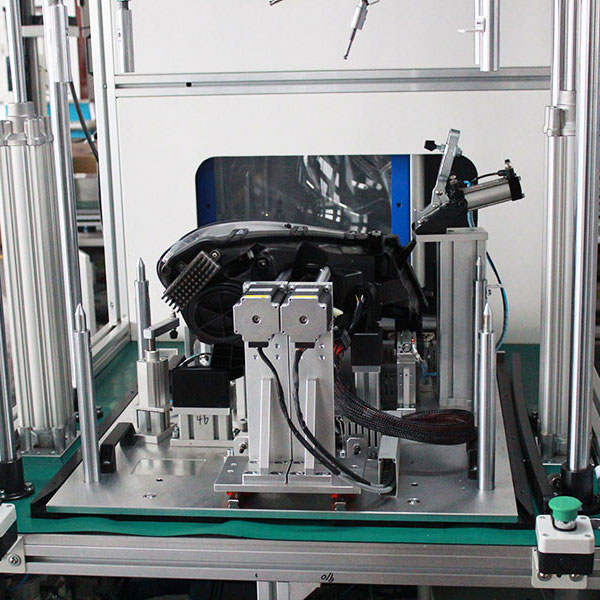

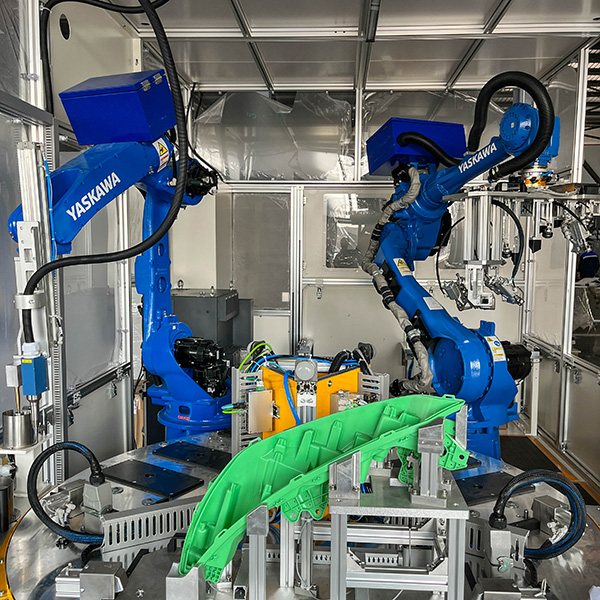

For OEM automotive lighting projects, photometric testing is not only a final checkpoint but an integral part of product development. During the prototyping stage, test data helps engineers fine-tune optical designs, adjust projector lenses, and optimize reflector geometry. This iterative testing approach ensures that lighting systems meet compliance requirements while also achieving optimal visual performance and aesthetic appeal. In mass production, photometric testing supports consistency and quality control. Even with high-precision tooling and automated assembly lines, small variations in components or alignment can affect light output. Integrating photometric testing into the production line allows manufacturers to monitor performance in real time, detect deviations quickly, and maintain stable quality across large production volumes. This is particularly important for export-oriented manufacturers supplying multiple global markets.

At Jinway Technology, photometric testing is closely integrated with assembly lines and final inspection systems to support zero-defect manufacturing goals. By combining photometric optic test machines with air leakage detection, visual inspection, and engraving systems, Jinway helps OEM customers achieve full traceability and compliance assurance. Each tested product carries verified performance data, providing confidence for both manufacturers and regulatory authorities. Beyond compliance, photometric testing also contributes to brand reputation and customer trust. Automotive lighting is a highly visible component that directly influences driving experience and perceived vehicle quality. Consistent, well-controlled lighting performance reflects a manufacturer’s commitment to safety, engineering excellence, and global standards. As automotive lighting technologies continue to evolve—especially with the rise of LED, adaptive, and intelligent lighting systems—the importance of precise photometric testing will only increase. By ensuring that every lamp meets international regulations and performance expectations, photometric testing remains a cornerstone of reliable, safe, and globally compliant automotive lighting production.