How Modular Assembly Lines Support Multiple Vehicle Platforms

Modern automotive markets demand flexibility. Vehicle models evolve rapidly, production volumes fluctuate, and lighting designs vary significantly between platforms. Traditional fixed assembly lines, built for a single product, struggle to keep pace with this environment. Modular assembly lines provide a solution by allowing manufacturers to adapt quickly while maintaining high efficiency and quality standards. A modular assembly line is built from independent yet interconnected workstations, each responsible for a specific process such as lens installation, projector alignment, dispensing, curing, or final inspection. Instead of redesigning the entire line when a new lamp model is introduced, manufacturers can modify, add, or rearrange modules to match new requirements. This structure supports multiple vehicle platforms without requiring a complete production overhaul.

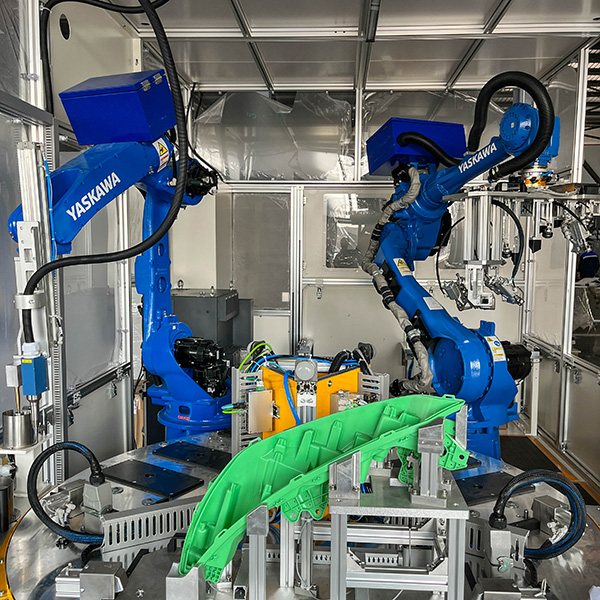

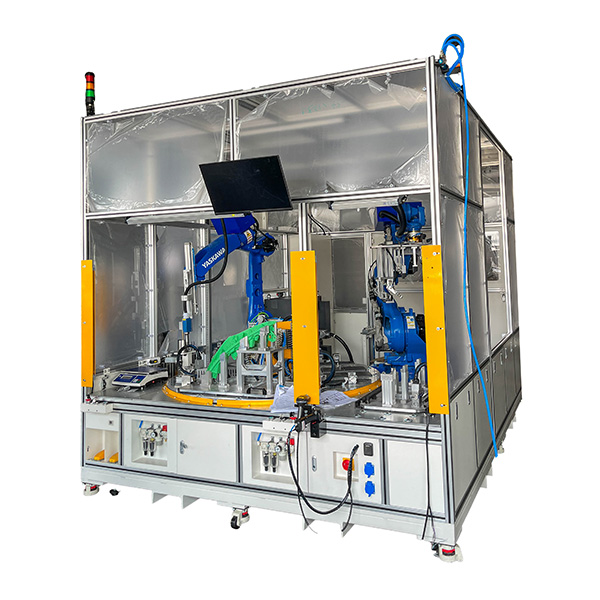

One of the key advantages of modular design is scalability. When production demand increases, additional modules can be added to boost capacity. When demand decreases or shifts to another model, modules can be reassigned. This flexibility reduces idle equipment and allows manufacturers to maximize return on investment. For OEM suppliers serving multiple automakers, this adaptability is especially valuable. Different vehicle platforms often require variations in lamp size, geometry, or function—such as LED matrix modules, adaptive lighting systems, or different housing designs. Modular assembly lines accommodate these differences by using adjustable fixtures, programmable robots, and quick-change tooling. Changeovers can be completed quickly, minimizing downtime and enabling mixed-model production within the same facility.

Automation integration is another benefit. Each module can incorporate specialized automation suited to its task, such as robotic dispensing, optical alignment systems, or photometric testing equipment. Because modules operate semi-independently, upgrades can be implemented step by step rather than disrupting the entire line. This supports continuous improvement and technology adoption without major production interruptions. Quality control becomes more effective in modular systems. Inspection modules can be placed at critical points in the process to catch defects early. For example, leak testing can follow sealing operations, while photometric testing can verify optical performance after assembly. This distributed inspection approach reduces defect propagation and supports zero-defect manufacturing goals.

Modular lines also enhance engineering collaboration. During new vehicle development, engineers can configure a pilot setup using selected modules to validate processes before full-scale production. This shortens development cycles and helps OEM customers launch new platforms faster. Process validation at the modular level reduces risk when transitioning to mass production. Maintenance efficiency improves as well. If one module requires servicing, it can often be isolated without stopping the entire line. Spare modules may be swapped in, maintaining productivity. Standardized module designs simplify spare parts management and technician training.

Digital manufacturing systems further strengthen modular assembly lines. Data from each module—cycle times, quality metrics, equipment status—can be integrated into central monitoring systems. This visibility enables predictive maintenance, performance optimization, and quick troubleshooting, ensuring consistent output across different product types. In the era of diversified vehicle platforms, modular assembly lines are no longer a luxury but a necessity. They allow lighting manufacturers to respond quickly to OEM demands, support multiple models efficiently, and maintain high quality with reduced operational risk. By combining flexibility, automation, and smart integration, modular assembly lines form the backbone of future-ready automotive lighting production.