Designing Flexible Coating Lines for Multi-Model Automotive Programs

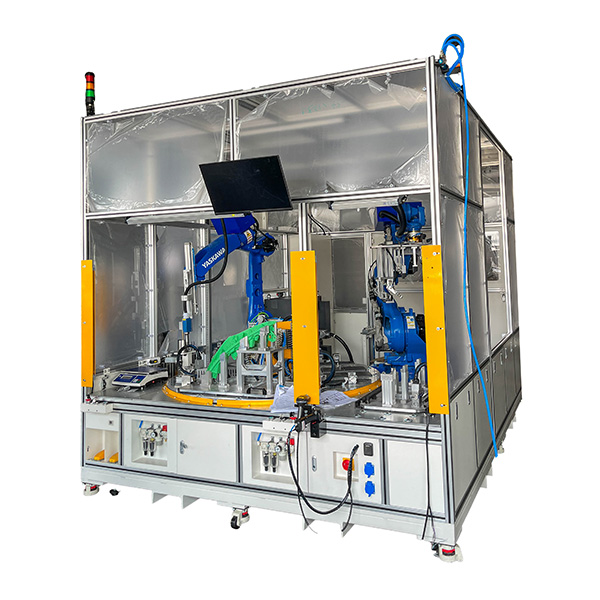

Automotive lighting manufacturers today rarely produce just one lamp design at a time. OEM programs overlap, vehicle facelifts happen quickly, and new models enter production before older ones leave. This environment makes rigid, single-purpose coating lines inefficient and costly. Designing flexible coating lines has become essential for supporting multi-model automotive programs without sacrificing quality or productivity. Flexibility begins with line architecture. Instead of a fixed layout optimized for one part geometry, modern coating lines use modular stations for cleaning, pre-treatment, coating, flash-off, curing, and cooling. Each section can be adjusted or reconfigured depending on the product. This modular design allows manufacturers to introduce new lamp lenses or housings with minimal structural changes to the line.

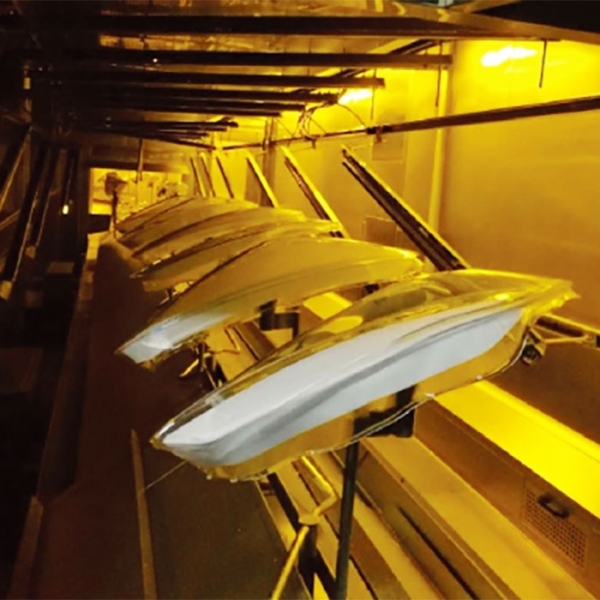

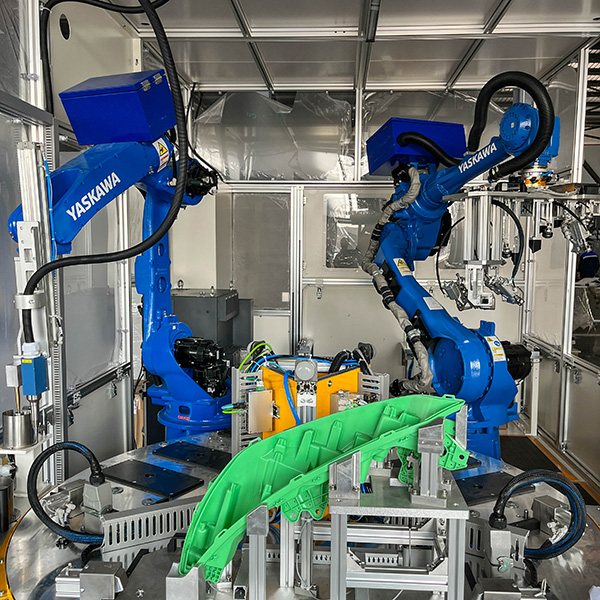

Part handling systems are a major factor in adaptability. Automotive lighting components vary in size, shape, and surface sensitivity. Flexible coating lines use adjustable carriers, universal fixtures, and programmable conveyors to accommodate different parts. Quick-change tooling systems allow operators to switch between models rapidly, reducing downtime and making small-batch or mixed-model production more feasible. Coating application technology must also be versatile. Different lamp models may require UV hard coatings, anti-fog coatings, decorative layers, or functional films. Advanced spray systems with programmable parameters—such as flow rate, spray pattern, atomization pressure, and path trajectory—allow one machine to handle multiple coating types. Robotic applicators ensure consistent coverage while adapting to different part geometries through software adjustments rather than mechanical changes.

Curing systems play a central role in flexible design. Some coatings require UV curing, others need thermal curing, and certain applications use hybrid processes. A flexible line integrates multiple curing options or adjustable curing zones. Variable lamp intensity, conveyor speed control, and segmented heating zones allow precise curing profiles for different materials without overhauling the equipment. Environmental control is equally important. Coating performance depends on temperature, humidity, and air cleanliness. Flexible lines maintain stable environmental conditions while allowing parameter adjustments based on coating chemistry. Smart ventilation and filtration systems help manage overspray and airborne particles, ensuring surface quality across diverse product runs.

Digital control systems are the backbone of multi-model operation. Modern coating lines rely on programmable logic controllers and manufacturing execution systems to store “recipes” for each product. Operators can switch production modes with minimal manual input, and the system automatically adjusts application settings, curing parameters, and conveyor speeds. This reduces human error and ensures repeatable quality. Quality assurance must be integrated into the line’s flexibility. In-line inspection modules—such as thickness measurement, surface defect detection, and curing verification—help ensure that changes in setup do not affect coating performance. Data from each production batch can be logged and traced back to specific process settings, which is critical when serving multiple OEM programs with strict compliance requirements.

Maintenance and scalability also influence flexible line design. Equipment that supports easy access, standardized components, and upgrade-ready modules allows manufacturers to expand capacity or integrate new technologies without rebuilding the entire system. This protects investment and keeps the line future-ready as coating technologies evolve. Designing flexible coating lines is ultimately about balancing adaptability with precision. By combining modular structure, programmable automation, adjustable curing, and smart process control, manufacturers can efficiently support multiple automotive lighting models on a single line. This approach reduces costs, shortens changeover time, and ensures that every coated component meets the demanding performance standards of global automotive programs.