Leveling Motors Explained: Ensuring Beam Stability on Every Road

Automotive lighting performance depends not only on light output but also on beam stability under real driving conditions. Changes in vehicle load, acceleration, braking, and road slope can alter the headlamp angle, potentially reducing visibility or causing glare for oncoming traffic. Leveling motors are designed to address this challenge by automatically adjusting the headlamp position, ensuring consistent and safe beam alignment on every road. A leveling motor is a compact electromechanical component integrated into the headlamp assembly. Its primary function is to adjust the vertical aim of the headlamp based on vehicle attitude. When a vehicle carries heavy cargo or passengers, the rear suspension may compress, causing the front of the vehicle to lift slightly. Without correction, this would raise the beam angle and increase glare. The leveling motor compensates by repositioning the headlamp downward to maintain the correct beam pattern.

Modern leveling motors operate in conjunction with sensors that detect vehicle pitch and load changes. These sensors send signals to the vehicle’s control unit, which calculates the necessary adjustment and activates the motor. The result is a precise and smooth correction that occurs automatically, often unnoticed by the driver. This real-time adjustment ensures compliance with road safety regulations while improving nighttime driving comfort. Precision is critical in leveling motor design. The motor must deliver accurate movement in very small increments to maintain beam alignment within strict regulatory tolerances. Gear mechanisms, drive screws, and position feedback systems are engineered to provide stable motion without backlash or vibration. High repeatability ensures that the headlamp returns to its correct reference position every time the system is activated.

Durability is another key requirement. Leveling motors operate in harsh environments, exposed to heat, vibration, moisture, and dust. Materials and sealing designs must protect internal components from degradation over the vehicle’s lifetime. High-quality motors are tested through extensive life-cycle simulations, including temperature cycling and vibration testing, to ensure long-term reliability. Integration with advanced lighting technologies further increases the importance of leveling motors. LED, projector, and adaptive lighting systems produce highly controlled beam patterns with sharp cutoffs. Even slight misalignment can affect performance or cause glare. Leveling motors help maintain the precise optical geometry required for these advanced systems to function as intended.

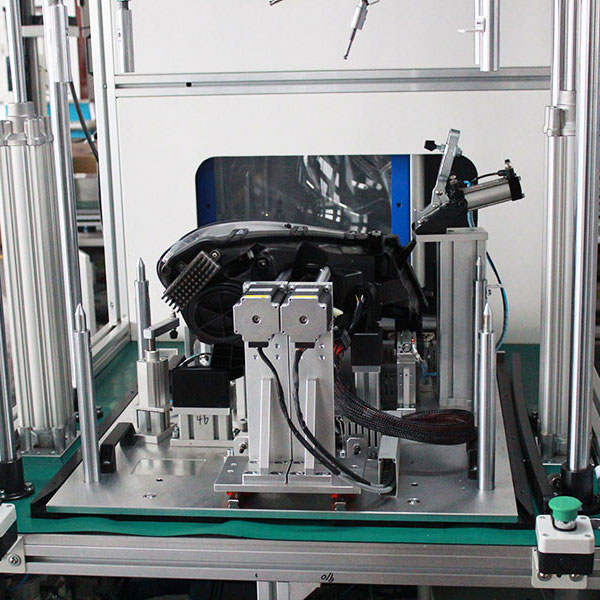

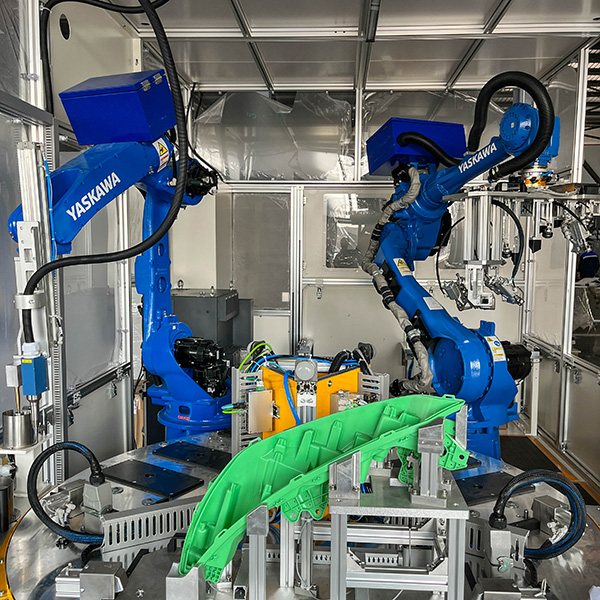

From a manufacturing perspective, consistency and quality control are essential. Leveling motors must be assembled and calibrated with tight tolerances to ensure uniform performance across large production volumes. Automated assembly lines and functional testing systems verify motor response, travel range, and positional accuracy before installation into the headlamp unit. Leveling motors also contribute to global regulatory compliance. Many international lighting standards require automatic leveling for certain headlamp types, particularly high-intensity or LED systems. By ensuring correct beam alignment under varying load conditions, leveling motors help vehicles meet these regulations in different markets without design changes.

In everyday driving, the benefits of leveling motors are subtle but significant. Drivers enjoy stable illumination of the road ahead, while other road users are protected from excessive glare. This balance between visibility and safety underscores the importance of leveling motors as a core component of modern automotive lighting systems. As vehicle technologies continue to advance, leveling motors will evolve alongside them—becoming smaller, more precise, and more integrated with intelligent lighting controls. Their role in ensuring beam stability remains essential, supporting safer roads and a more comfortable driving experience in all conditions.