Why Photometric Optic Test Machines Are Critical for Headlamp Approval

Headlamp approval is a mandatory gateway before any vehicle can enter the market. Regulatory authorities do not evaluate lighting systems based on brightness alone—they require precise confirmation that beam distribution, glare control, and luminous intensity meet strict safety standards. Photometric optic test machines are therefore indispensable, providing the scientific measurements needed to validate compliance and ensure safe road performance. At the heart of headlamp approval lies photometry—the measurement of light intensity at specific angles and distances. Regulations such as ECE, SAE, FMVSS, and GB define exact test points where light must fall within specified minimum and maximum limits. Too little light reduces forward visibility; too much light in certain zones can blind oncoming drivers. Photometric optic test machines measure these values with high-resolution sensors, ensuring every beam meets regulatory thresholds.

One of the most critical elements in approval testing is the cutoff line. Modern low-beam headlamps, especially projector and LED systems, must produce a sharp horizontal cutoff that prevents glare while illuminating the road ahead. Even minor deviations in optical alignment can blur or shift this cutoff. Photometric test machines capture detailed beam images and intensity maps, allowing engineers to evaluate cutoff sharpness and position with precision beyond human visual inspection. Global market access further increases the importance of accurate testing. Different regions impose slightly different photometric requirements. A headlamp designed for Europe may require adjustments to comply with North American standards. Photometric optic test machines simulate these regulatory environments and generate data that engineers can compare against multiple international benchmarks, reducing redesign risk and shortening approval timelines.

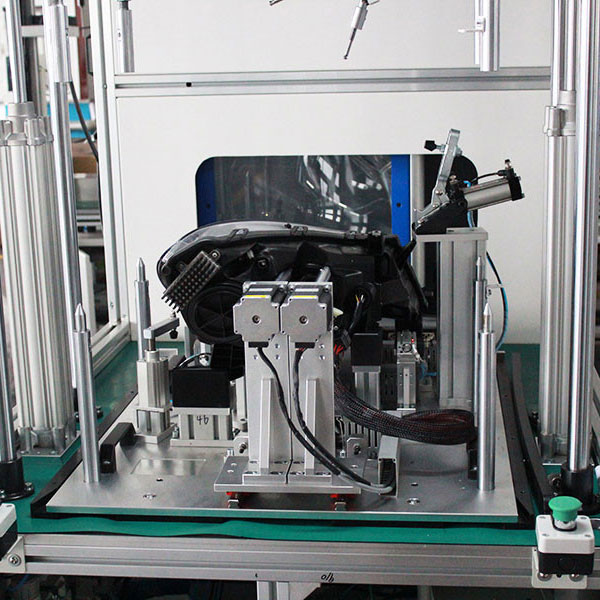

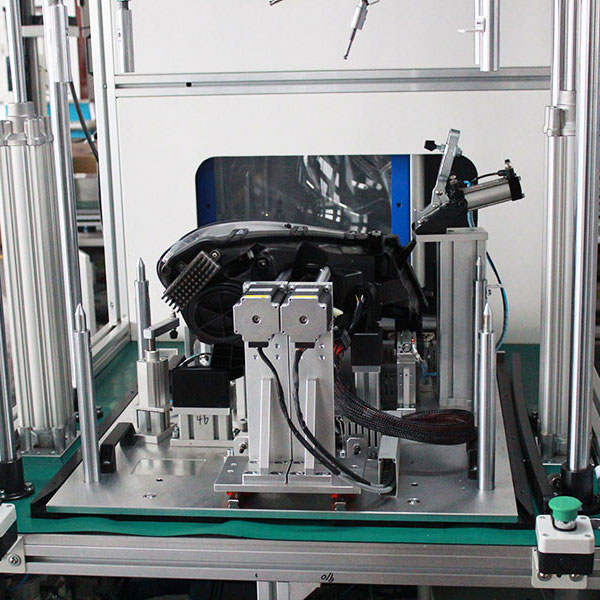

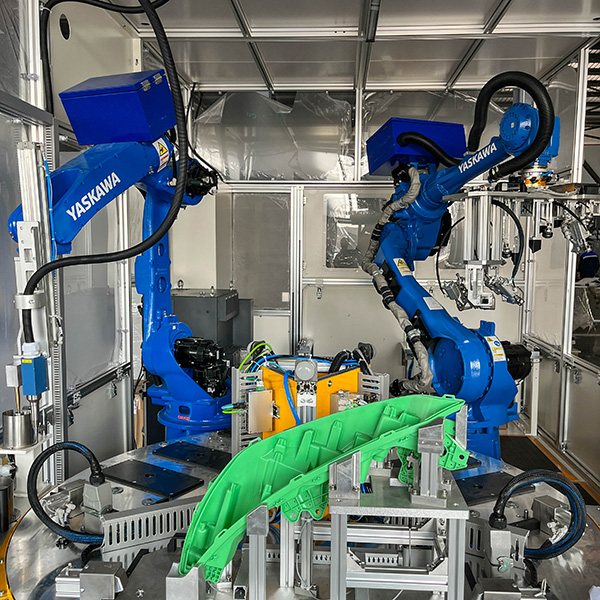

During development, these machines act as essential diagnostic tools. Engineers rely on real photometric data to refine reflector geometry, adjust lens curvature, or optimize LED placement. Small structural changes can dramatically alter beam distribution, and without precise measurement equipment, it would be impossible to quantify these effects accurately. Photometric testing accelerates development cycles by guiding data-driven improvements. In mass production, consistency becomes just as important as initial compliance. Even with advanced tooling and automated assembly, slight variations in alignment, component tolerances, or curing conditions can influence light output. Integrating photometric testing into end-of-line inspection ensures that each unit matches approved performance standards. This prevents non-compliant lamps from reaching customers and protects manufacturers from costly recalls.

Advanced lighting technologies make photometric verification even more critical. Adaptive headlights, matrix LEDs, and dynamic bending light systems create complex beam patterns that change based on driving conditions. Photometric optic test machines are capable of evaluating both static and dynamic performance, confirming that these intelligent systems operate within regulatory limits under all scenarios. Traceability is another major advantage. Approval authorities and OEM customers often require documented evidence of compliance. Modern photometric systems generate digital reports, beam images, and data logs that can be stored for audits and certification records. This documentation provides confidence that the product meets global standards not just in theory, but in measurable performance.

Durability testing also relies on photometric verification. Over time, components may degrade due to heat, UV exposure, or vibration. By conducting photometric measurements before and after environmental testing, manufacturers can confirm that light output remains within approved limits throughout the product’s lifespan. This ensures long-term compliance, not just initial certification. Ultimately, photometric optic test machines are critical because they transform lighting performance into objective, quantifiable data. They safeguard regulatory approval, support engineering optimization, ensure production consistency, and protect road safety. In the highly regulated automotive industry, reliable photometric testing is not simply a quality tool—it is the foundation of headlamp approval and global market success.