Anti-Fog Coating Technology: Improving Safety and Visibility on the Road

Clear visibility is one of the most critical elements of safe driving. Whether during cold mornings, abrupt weather changes, or humid environments, fogged automotive lamps and mirrors can significantly reduce a driver’s ability to see and be seen. As modern vehicles become more advanced, consumers and OEM manufacturers demand lighting systems that perform consistently under all conditions. This is where anti-fog coating technology plays a transformative role. It ensures that headlights, taillights, fog lamps, and even interior lighting components maintain maximum clarity, no matter what the road or weather presents.

Fogging occurs when moisture condenses on cooler surfaces, such as the inner or outer side of a lamp lens. This condensation diffuses light output and reduces the effectiveness of the illumination. For headlamps, this loss of clarity can diminish beam quality, shorten visibility range, and potentially increase reaction time during nighttime or low-visibility driving. Anti-fog coating technology was developed to counter this challenge by providing a treated surface that resists condensation and keeps the lighting output crisp and bright.

The science behind anti-fog coatings typically involves hydrophilic materials that spread water droplets into ultra-thin, transparent layers rather than allowing them to form visible mist or beads. Instead of scattering light, this uniform water film maintains high transparency. In some advanced systems, hydrophobic coatings are used to repel water altogether, preventing moisture from settling on the lens surface. Both approaches significantly enhance optical clarity and ensure that lamps perform reliably in humid, rainy, or cold environments.

In the automotive lighting industry, anti-fog coating technology has become a fundamental requirement, especially as OEM manufacturers raise standards for durability and safety. Jinway Technology Co., Ltd. is actively contributing to this progress with its robust expertise in coating lines and advanced production systems. With strong partnerships and experience in UV coating, anti-fog processes, and assembly solutions, Jinway supports the full cycle of automotive lighting development—from early design recommendations to final inspection.

The integration of anti-fog coating is not just about enhancing performance but also ensuring long-term reliability. Condensation issues, if left untreated, can lead to multiple downstream problems. These include discoloration, corrosion of internal components, weakening of adhesives, and gradual reduction of light transmission—all of which compromise the overall lifespan of the lamp. Anti-fog coatings help maintain optical clarity while protecting the structural integrity of the lighting unit. This makes them invaluable not only for performance but also for cost efficiency, as fewer warranty claims, repairs, and replacements are needed.

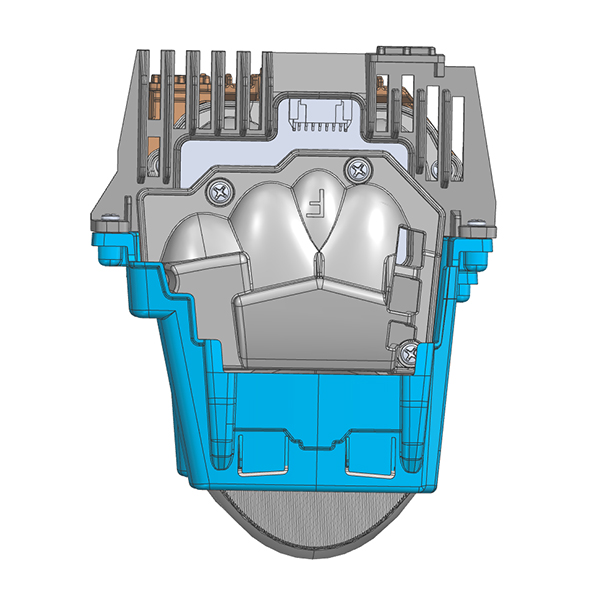

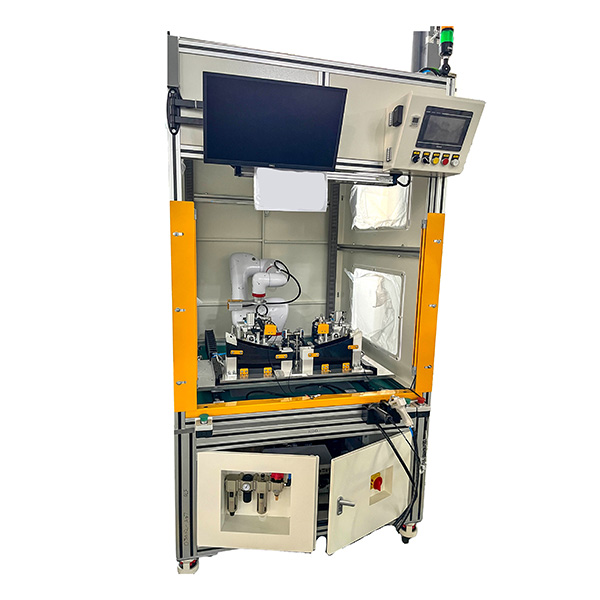

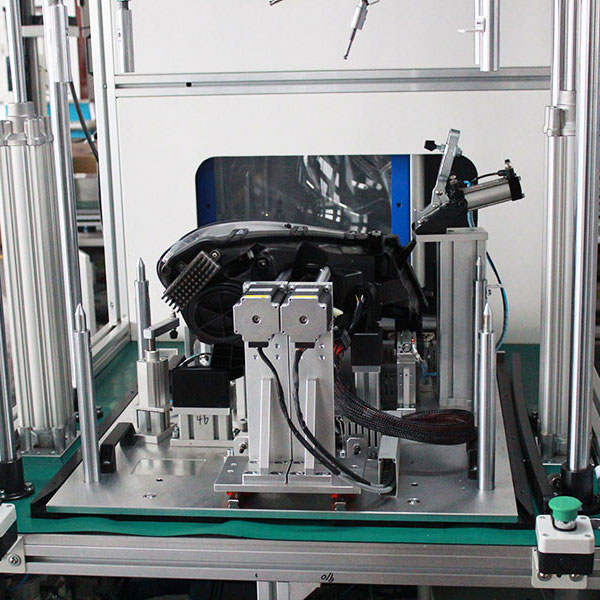

The application of anti-fog coatings requires precision, consistency, and advanced equipment. Jinway’s coating lines are designed to deliver uniform coverage, strong adhesion, and fast curing times. Every stage—surface preparation, coating application, drying, and testing—is optimized to meet strict OEM standards. Automated systems ensure that each lamp receives the exact amount of coating, eliminating variability and ensuring reliable performance across high-volume production. This level of technical accuracy reflects Jinway’s commitment to providing customers with products that meet the highest industry expectations.

Moreover, anti-fog coating technology contributes to safety in ways that go beyond traditional lighting performance. As vehicles adopt adaptive lighting systems, dynamic bending lights, and more complex optical structures, even small amounts of fogging can negatively affect beam shape and precision. Clear lenses are essential for ensuring that intelligent lighting functions operate accurately and consistently. Anti-fog coatings therefore play a crucial role in supporting the evolution of advanced vehicle technologies.

As global weather conditions become increasingly unpredictable, the demand for enhanced visibility and dependable lighting systems continues to grow. Anti-fog coating is no longer an optional feature—it is a necessity for modern automotive design. Jinway Technology recognizes this shift and continues developing specialized coating solutions that improve safety, enhance optical performance, and extend product longevity.

With a strong foundation in tooling, coating lines, assembly systems, and inspection equipment, Jinway remains a trusted partner for OEM manufacturers striving to elevate their automotive lighting products. Anti-fog coating technology represents just one area where Jinway’s technical expertise brings tangible improvements to road safety and driving confidence. By ensuring that every beam shines clearly under all conditions, anti-fog coatings make vehicles safer—and drivers more secure—wherever the journey leads.