Digital Twins in Factory Automation: Simulating Success Before Hardware Is Built

In the world of modern manufacturing, speed, precision, and adaptability are essential. Yet, the traditional model of building and testing physical systems before deployment can be costly, time-consuming, and prone to unforeseen issues. This is where digital twins—virtual replicas of physical systems—are transforming the factory automation landscape. At Jinway Technology Co., Ltd., we are embracing digital twin technology to simulate, validate, and optimize automation solutions before a single component hits the production floor. This article explores how digital twins improve design accuracy, reduce risk, and accelerate deployment timelines across a range of industrial applications.

What Is a Digital Twin?

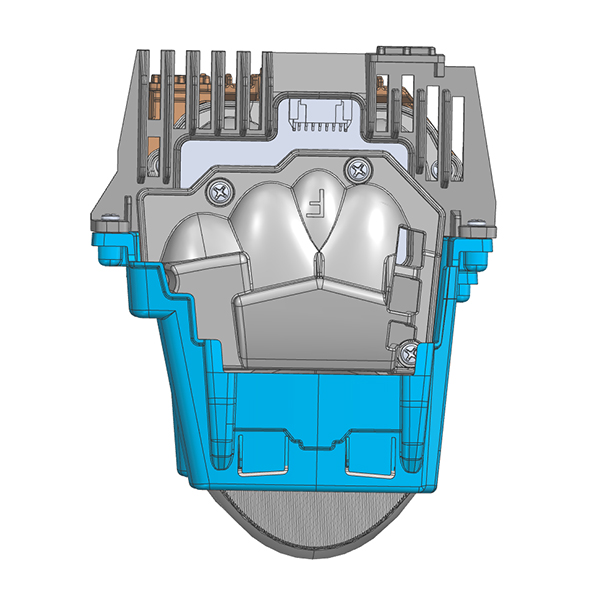

A digital twin is a high-fidelity virtual model of a physical machine, process, or production system. It replicates real-world behavior by incorporating data on geometry, motion, logic, sensors, and environmental conditions. The twin can be run in simulation software to mimic how the physical system would perform in a real factory setting—long before anything is physically assembled.

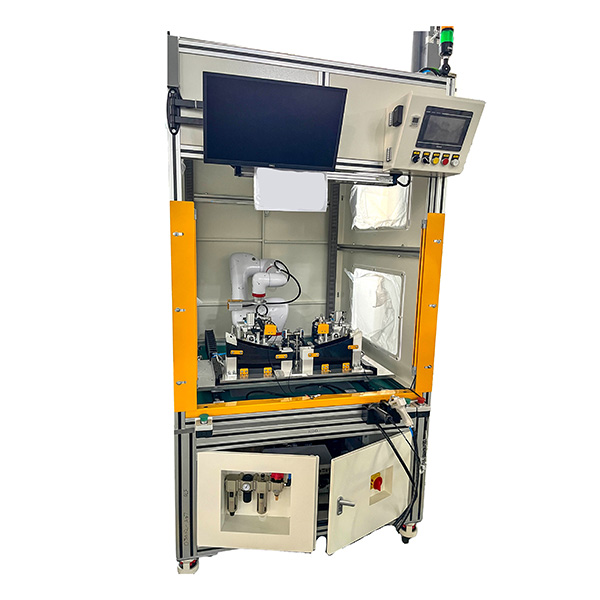

For automation, this means that entire production lines, robotic cells, or test stations can be modeled digitally. Motion paths, logic sequences, and human interactions can be tested virtually, providing an accurate picture of performance under real-world conditions.

Reducing Development Time and Costs

Building automation equipment is an investment, and delays caused by design errors or integration issues can be costly. By simulating systems using digital twins, we identify and resolve potential issues early in the design process. This reduces the number of prototype cycles required, lowers material waste, and shortens lead times.

Our engineering teams use digital twins to:

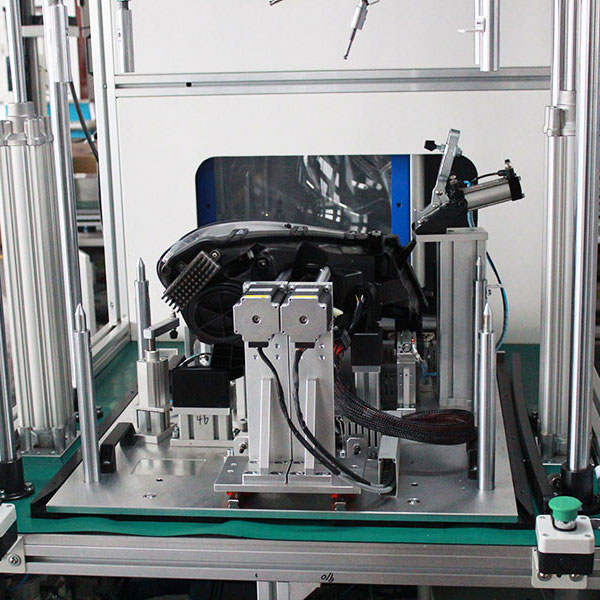

Verify mechanical clearances and robot reach

Validate PLC logic and sensor placement

Simulate part flow and takt time performance

Test user interfaces and safety interlocks

By catching these challenges digitally, we reduce on-site commissioning time and ensure that the first version of the physical system performs as intended.

Virtual Commissioning and PLC Testing

One of the most powerful applications of digital twins is virtual commissioning—testing and debugging PLC programs before deployment. We connect our control logic directly to the digital twin, allowing it to simulate responses from motors, actuators, and sensors in real time.

This means we can:

Validate sequence logic before the real machine is built

Run fault scenarios and verify safety responses

Tune performance settings in advance

Perform early operator training with the digital model

Virtual commissioning helps ensure that by the time the hardware is installed, the software is already proven. This reduces debugging time on site and minimizes disruption to existing production lines.

Improving Collaboration Across Teams

Digital twins serve as a central source of truth for collaboration between mechanical, electrical, software, and project management teams. Instead of waiting for the machine to be assembled, stakeholders can interact with the 3D simulation to review the concept, suggest changes, or conduct risk assessments.

This collaborative visualization fosters better alignment, especially in complex projects where multiple teams or vendors are involved. At Jinway, we use digital twin walkthroughs during client reviews to provide early visibility into design decisions and system behavior.

Enhancing Flexibility and Customization

Every customer’s production environment is unique, and standard automation systems rarely fit perfectly. With digital twins, we can test custom configurations for part handling, sensor positions, or vision alignment—ensuring that our solutions are precisely tailored to client needs.

For projects involving optical testing, lighting, or vision-based inspection, the ability to simulate lighting conditions, part surfaces, and image acquisition is particularly valuable. This helps optimize system layout and ensure robust defect detection before deployment.

Training and Operator Familiarization

Beyond engineering, digital twins are increasingly used to train operators and maintenance personnel. Instead of waiting for the system to be delivered, staff can begin interacting with the digital twin through human-machine interfaces (HMIs) and virtual environments.

This accelerates onboarding and reduces the learning curve once the system is physically installed. It also allows safety procedures and emergency scenarios to be rehearsed in a risk-free environment.

Data Feedback and Continuous Improvement

The value of digital twins doesn’t stop once the physical system is built. When connected to real-time production data, a digital twin can be used for performance monitoring, predictive maintenance, and continuous optimization.

For example, if the system begins to underperform, the digital twin can simulate how different changes—such as motor speeds or inspection timing—would affect output. This enables proactive adjustments without interrupting actual production.

Jinway’s solutions are designed to integrate seamlessly with factory data infrastructure, allowing clients to evolve their digital twins into live tools for decision support and system analytics.

Future-Proofing Automation Investments

Digital twin technology plays a vital role in building flexible, adaptable systems. As production requirements shift—whether due to product changes, volume increases, or quality improvements—the digital twin can be updated to simulate modifications and validate upgrades before making hardware changes.

This forward-thinking approach helps protect our clients’ investments by making systems easier to adapt, scale, and optimize over time.

Conclusion

Digital twins represent a leap forward in how automation systems are designed, tested, and deployed. By enabling us to simulate success before building hardware, they reduce risk, cut costs, and improve collaboration across the project lifecycle. At Jinway Technology Co., Ltd., we are integrating digital twin technology into every stage of our solution development process—ensuring that our automation and testing systems are not only accurate but also ready for the demands of the future.