Eliminating Condensation Risks in Headlamp Design Through Process Control

Condensation inside headlamps is one of the most common and frustrating challenges faced in modern vehicle lighting. While moisture droplets may be small, their impact can be big—reducing beam clarity, affecting optical patterns, and potentially causing warranty claims. Eliminating condensation risks requires more than a clever lamp design; it depends on rigorous process control from tooling to assembly and testing. Headlamp condensation typically forms when humidity becomes trapped within the lamp housing and condenses on the inside surface of the lens during temperature fluctuations. Vehicles experience wide environmental swings—from hot daytime driving to cold rain or nighttime temperatures. If any moisture exists inside the lamp or if pressure cannot equalize properly, condensation becomes inevitable. That is why manufacturers must tackle moisture intrusion long before the product leaves the factory.

Precision tooling plays a foundational role in minimizing condensation risk. Tooling that ensures accurate mating surfaces and uniform material thickness helps produce housings and lenses with consistent sealing interfaces. Even a microscopic gap caused by poor mold accuracy or part warpage can allow air and moisture to migrate. High-quality molds, controlled temperature settings, and dimensional monitoring help produce parts that seat perfectly during assembly. Material selection is equally critical. Lamp housings often use plastics with low moisture absorption, while rubber gaskets and sealants must maintain flexibility and compression over the vehicle’s lifetime. Choosing the wrong gasket formulation—or one that degrades under UV or engine heat—can lead to seal failure. Process control ensures every batch of materials meets specification before entering production, preventing unseen variation from turning into moisture problems later.

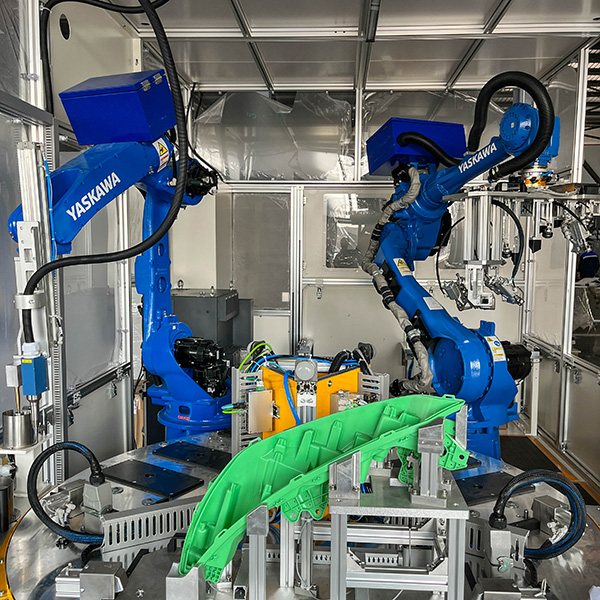

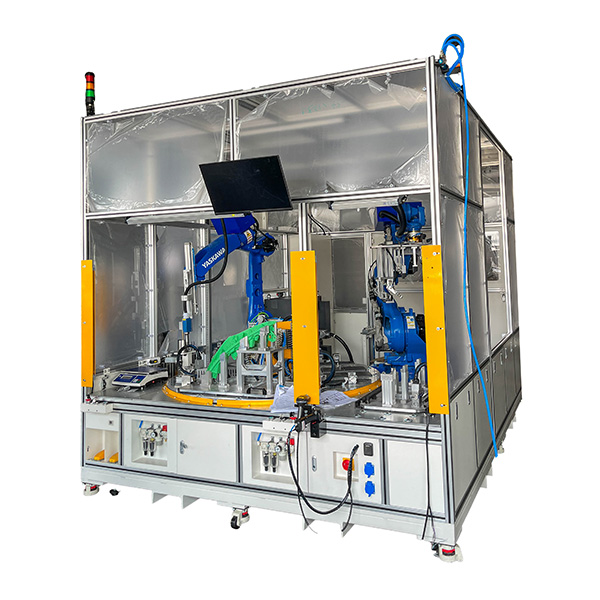

Sealing processes are where many condensation failures originate. Automated dispensing of adhesives and sealants ensures correct bead placement, bead volume, and surface wet-out across every lamp. If an adhesive is too thin, misplaced, or poorly cured, gaps may form even if the parts are perfectly manufactured. Advanced dispensing machines, combined with robotic paths and programmed accuracy, guarantee that sealing lines are applied to exact tolerances every time. Curing conditions for sealants and coatings must also be precisely controlled. Under-curing leaves weak bonds that slowly leak moisture; over-curing may crack or shrink sealants. Temperature, humidity, time, and UV exposure (when used) need to be monitored and recorded. This step often separates high-quality manufacturers from those relying on manual judgment. A controlled curing schedule creates uniform seals that remain robust under real-world stress.

Vent solutions are another tool for controlling condensation. Modern headlamps are designed to breathe—not leak. Special membranes or vents equalize pressure while blocking water. However, the placement, installation method, and cleanliness of vent components are highly sensitive factors. Process audits ensure vent holes remain unobstructed, membranes stay intact, and no contaminants interfere with airflow. Leak testing and moisture checks during final inspection act as a final safety net. Automated air-pressure decay tests, vacuum leak checks, and fog simulation chambers help detect defects that visual inspection might miss. These tests validate the cumulative accuracy of molding, sealing, and assembly steps before shipping.

When strong process control is in place, condensation becomes predictable and preventable—not a matter of luck. Lamp makers who enforce rigorous discipline across manufacturing—from raw materials to automated sealing and robust inspection—deliver durable headlamps that stay clear, bright, and reliable even in the most demanding environments. In a market where automakers expect zero returns, process control is not merely best practice—it is the core of dependable headlamp design.