From Manual to Automated: Upgrading Legacy Lighting Production Lines

Condensation inside headlamps is a persistent challenge in automotive lighting, affecting visibility, aesthetics, and long-term reliability. When moisture accumulates inside a lamp housing, it can scatter light, distort beam patterns, accelerate corrosion, and damage sensitive electronic components. Eliminating condensation risks is not simply a design concern—it is a manufacturing discipline driven by precise process control at every stage of production. Condensation occurs when humid air becomes trapped inside the headlamp and temperature changes cause water vapor to condense on internal surfaces. Vehicles experience rapid thermal shifts from engine heat, sunlight, rain, and nighttime cooling. If sealing systems are imperfect or moisture remains inside during assembly, condensation becomes unavoidable. Effective prevention starts by controlling the manufacturing environment and ensuring moisture is never introduced in the first place.

Precision tooling is the foundation of condensation-free headlamp production. High-accuracy molds ensure that lenses, housings, and mating surfaces fit together seamlessly without micro-gaps. Variations in flatness or alignment can create invisible pathways for air and moisture to enter. Maintaining tight dimensional tolerances through advanced machining, mold maintenance, and regular calibration ensures consistent part geometry and reliable sealing interfaces. Material selection plays a critical role in moisture management. Plastics used for housings must exhibit low moisture absorption and high dimensional stability, while gaskets and sealants must maintain elasticity and compression across wide temperature ranges. Selecting materials with proven resistance to heat, UV exposure, and aging helps preserve sealing integrity throughout the lamp’s service life. Strict incoming material inspection prevents batch variation from undermining long-term performance.

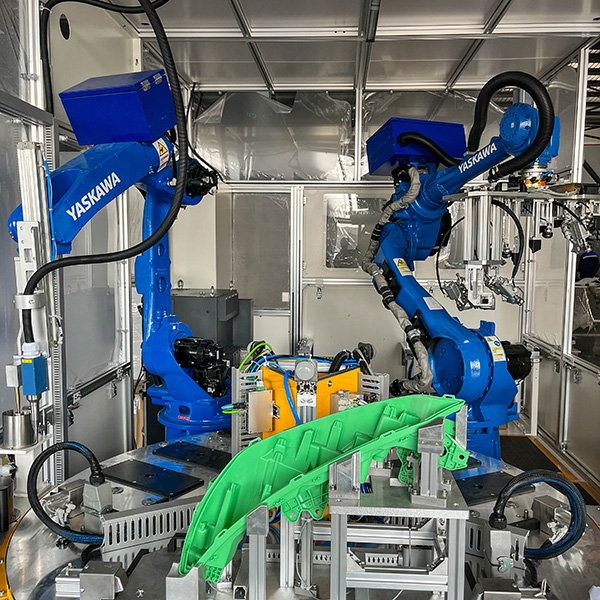

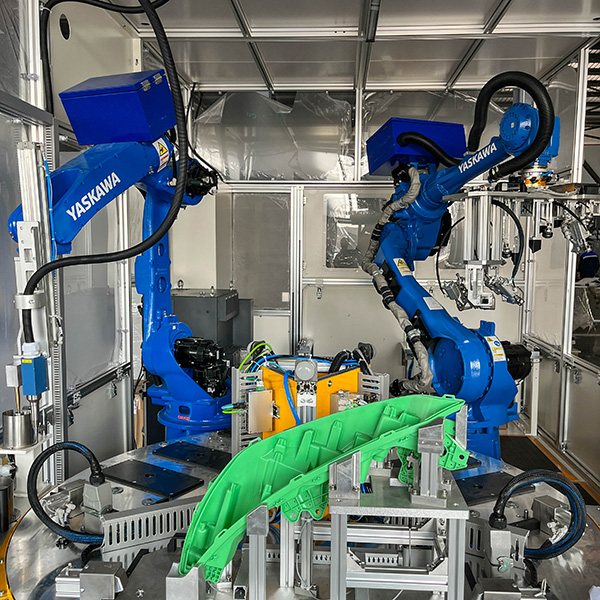

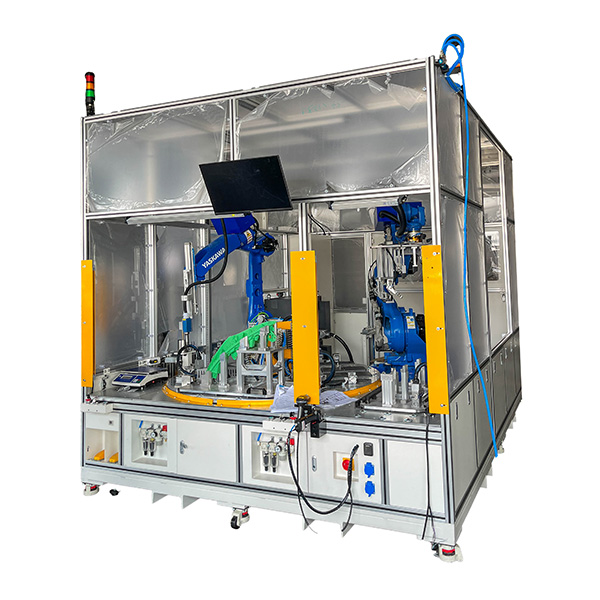

Sealing processes represent one of the most important control points in preventing condensation. Automated dispensing systems apply adhesives and sealants with precise bead width, height, and placement along lamp joints. Uniform sealant distribution ensures continuous barriers without gaps or excess material. Robotic dispensing reduces human error and ensures repeatability, which is essential for maintaining consistent quality in high-volume production environments. Curing conditions for sealants and coatings must also be carefully controlled. Under-cured sealants may remain porous or weak, allowing moisture infiltration over time, while over-curing can cause shrinkage or cracking. Monitoring temperature, humidity, UV exposure, and curing duration ensures the sealant reaches optimal mechanical strength and adhesion. Data-driven curing control transforms sealing from a variable step into a predictable and repeatable process.

Ventilation systems provide another layer of protection against condensation. Modern headlamps often incorporate breathable membranes that equalize internal pressure while blocking water ingress. Proper vent placement, installation accuracy, and cleanliness are critical to their effectiveness. Process control ensures vents remain unobstructed and correctly positioned, allowing lamps to “breathe” without compromising moisture protection. Environmental control during assembly is equally important. High-humidity production environments can trap moisture inside lamps before sealing occurs. Controlled assembly zones with regulated temperature and humidity reduce the risk of residual moisture being enclosed during final assembly. Cleanroom-style practices further minimize contamination that could compromise sealing performance.

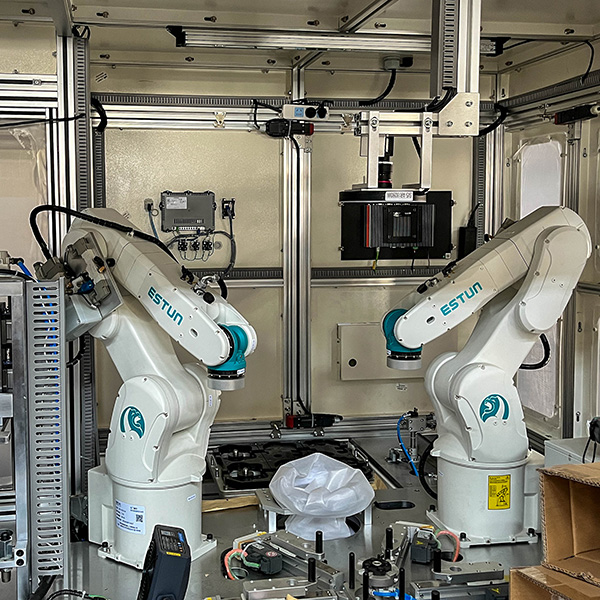

Inspection and validation serve as the final safeguards against condensation-related defects. Leak testing methods such as pressure decay tests, vacuum checks, and fogging simulations verify sealing integrity before products leave the production line. These tests identify weaknesses that may not be visible through standard visual inspection, ensuring only fully sealed lamps reach customers. Ultimately, eliminating condensation risks is a system-level achievement. It requires coordination between tooling precision, material quality, automated sealing, controlled curing, environmental management, and rigorous inspection. When every process step is aligned, condensation becomes a controlled variable rather than an unpredictable failure mode. In modern automotive lighting manufacturing, process control is the difference between short-term performance and long-term reliability. By embedding moisture prevention into every stage of production, manufacturers deliver headlamps that remain clear, bright, and dependable throughout years of real-world driving conditions.