Engineering Anti-Yellowing Solutions for Long-Life Headlamp Lenses

Headlamp lenses are among the most exposed components on a vehicle, constantly facing sunlight, heat, moisture, chemicals, and road debris. Over time, these environmental factors can cause lens materials—especially plastic lenses—to yellow, haze, or lose transparency. This degradation not only affects vehicle appearance but also reduces light output and compromises driving safety. Engineering effective anti-yellowing solutions has therefore become a critical focus in long-life headlamp lens manufacturing. Yellowing is primarily caused by ultraviolet (UV) radiation and thermal aging. Prolonged UV exposure breaks down polymer chains in lens materials, leading to discoloration and surface oxidation. Heat generated by lighting sources and environmental temperature cycles accelerates this process, while moisture and chemical exposure further contribute to surface degradation. Without proper protection, even high-quality optical materials can suffer noticeable performance loss over time.

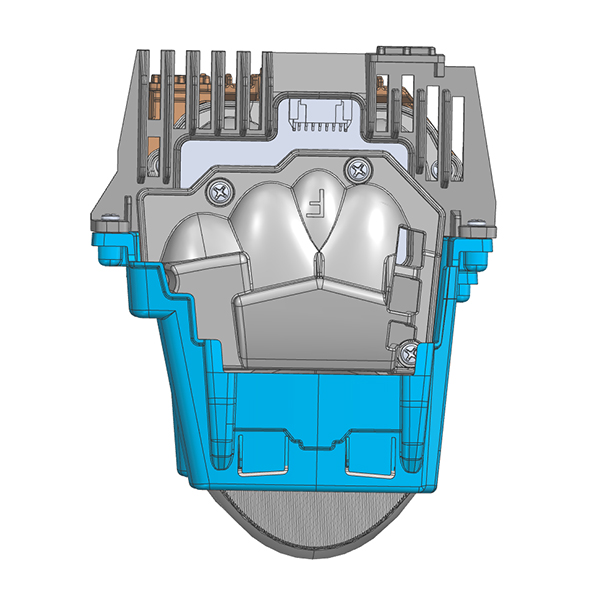

The foundation of anti-yellowing performance begins with material selection. Optical-grade polycarbonate and other advanced polymers are commonly used for headlamp lenses due to their impact resistance and clarity. However, these materials must be specially formulated with UV stabilizers and antioxidants to resist long-term degradation. Selecting materials with proven aging performance is a crucial first step toward extending lens lifespan. Surface protection plays an equally important role in preventing yellowing. UV coating technology is widely used to create a protective barrier that shields lenses from ultraviolet radiation, heat, and environmental contaminants. A well-engineered UV coating not only blocks harmful rays but also enhances scratch resistance and surface hardness. Uniform coating thickness and strong adhesion are essential to ensure long-term protection without affecting optical clarity.

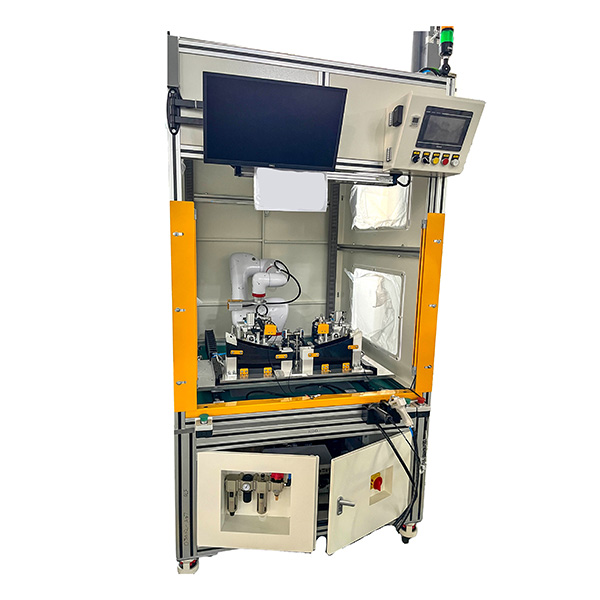

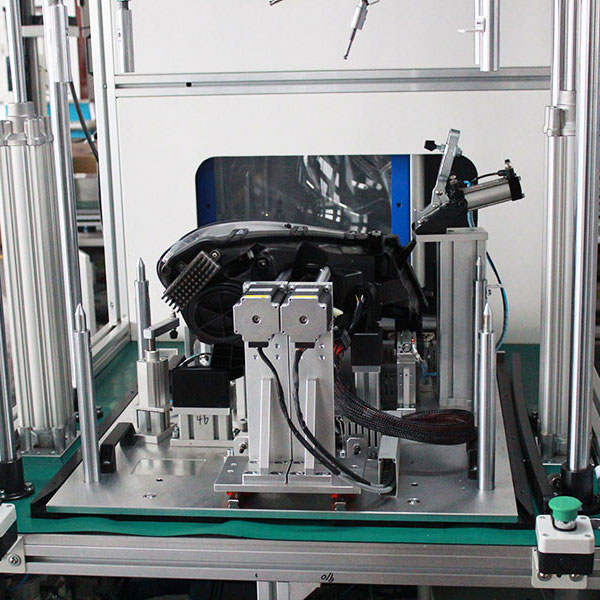

The coating process itself must be carefully engineered to deliver consistent results. Factors such as coating formulation, application method, curing temperature, and UV exposure time all influence the final performance. Advanced UV coating lines with precise process control help ensure uniform coverage and stable curing, reducing the risk of weak spots that could lead to premature yellowing. In addition to coating, lens design and manufacturing precision contribute to anti-yellowing performance. Smooth surface finishes reduce the likelihood of micro-cracks and stress points where degradation can begin. Precision tooling and controlled molding processes help minimize internal stress within the lens, improving resistance to thermal and environmental aging.

Testing and validation are essential to confirm the effectiveness of anti-yellowing solutions. Accelerated aging tests, UV exposure simulations, thermal cycling, and humidity testing allow manufacturers to evaluate long-term performance within shorter timeframes. Optical measurements before and after testing help verify that light transmission, clarity, and color stability remain within acceptable limits. At Jinway Technology, anti-yellowing engineering is approached as a complete system solution. By combining qualified materials, advanced UV coating lines, precision tooling, and rigorous testing processes, Jinway helps OEM customers produce headlamp lenses that maintain clarity and performance throughout the vehicle’s service life. This integrated approach not only enhances durability but also supports consistent quality across global markets.

As automotive lighting continues to evolve and vehicle lifespans extend, the demand for long-lasting, visually stable headlamp lenses will only grow. Through continuous innovation in materials, coatings, and manufacturing processes, engineered anti-yellowing solutions remain key to ensuring safety, aesthetics, and long-term value in modern automotive lighting systems.