Ensuring Safety and Standards: The Role of Photometric Optic Test Machines in Automotive Lighting

In the automotive industry, lighting is far more than a design feature—it's a critical safety component. Headlights, taillights, and indicators must perform flawlessly in all conditions to ensure road safety and regulatory compliance. At Jinway Technology Co., Ltd., we recognize the crucial role that precision lighting plays in today’s vehicles, and we’re proud to support this mission with our advanced Photometric Optic Test Machines.

What Is Photometric Testing?

Photometric testing refers to the process of evaluating the optical characteristics of automotive lamps. These tests measure key performance metrics such as luminous intensity, beam angle, light uniformity, and cutoff precision. The goal is to ensure every lamp meets strict international safety standards such as ECE (Europe), SAE (USA), and DOT.

These standards are not just checkboxes—they are safeguards that prevent glare, ensure visibility, and protect both drivers and pedestrians.

The Role of Photometric Optic Test Machines

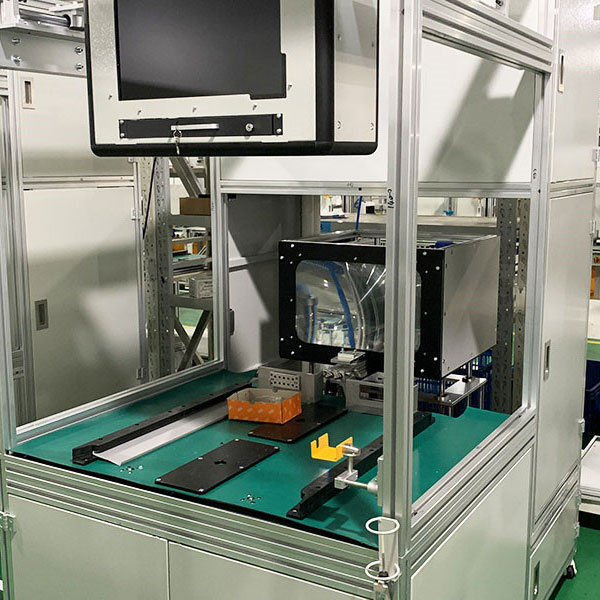

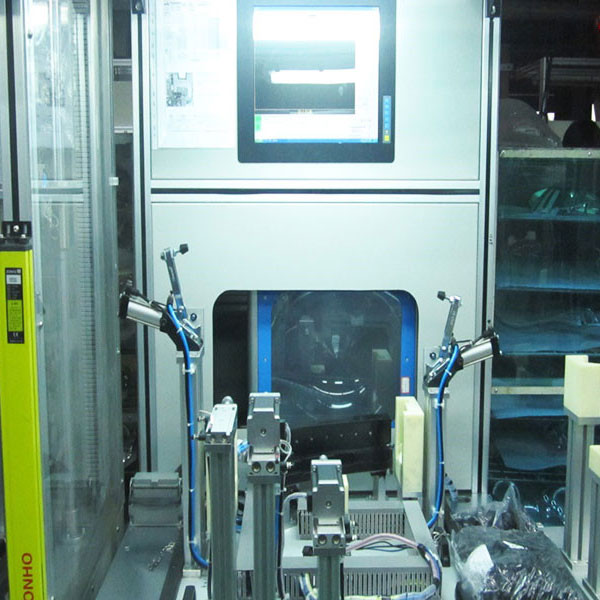

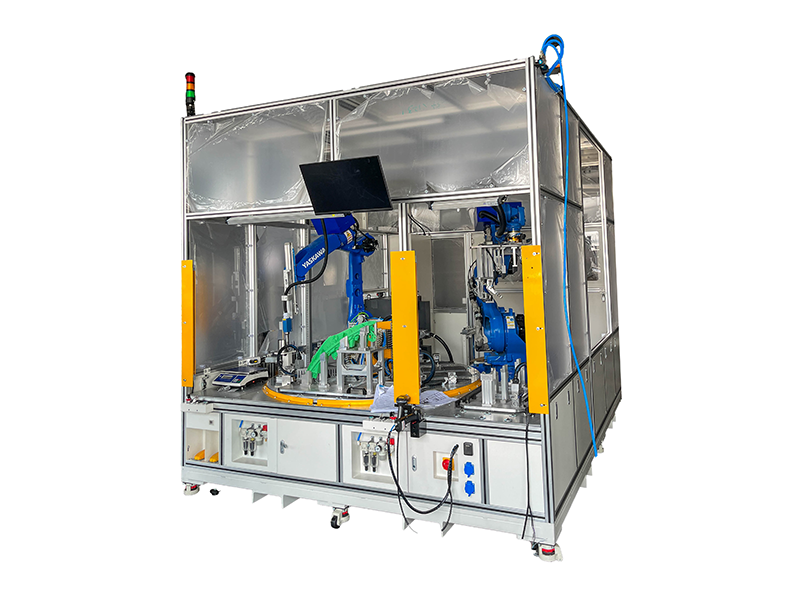

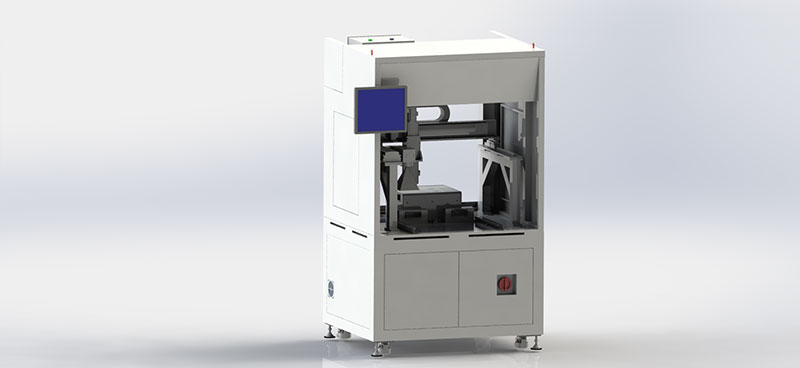

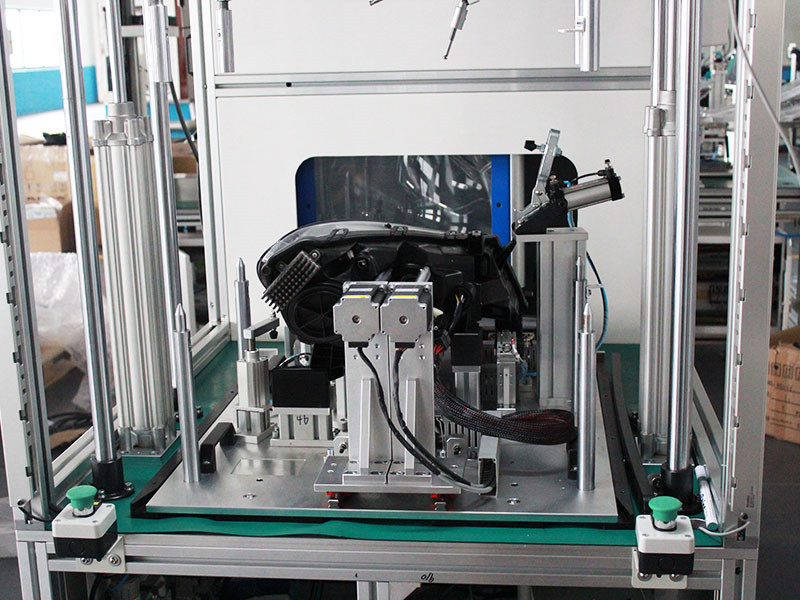

Photometric optic test machines are specialized systems designed to automatically test and verify the optical output of vehicle lighting components. At Jinway, our machines are equipped with high-precision sensors, light measurement modules, and intelligent control software to deliver accurate, repeatable, and rapid test results.

Our systems can be configured to test various lamp types, including halogen, xenon, LED, and even adaptive matrix beam systems.

Jinway's Integrated Testing Technology

At Jinway Technology, we go beyond just offering standalone testing devices. Our Photometric Optic Test Machines are designed to integrate seamlessly into full-scale automated production lines. This means lighting components can be assembled, optically tested, and passed or rejected without any manual intervention.

By integrating these systems with our broader product line—including Auto Lamp Assembly Lines, Mold Dispensing Machines, and Final Inspection Units—manufacturers benefit from a fully connected, intelligent production workflow.

Benefits of Automated Optical Testing

The adoption of automated photometric testing delivers significant advantages:

Improved product quality through consistent, high-precision measurements

Faster cycle times thanks to in-line automation

Lower risk of non-compliance with regulatory standards

Detailed data logging for traceability and quality control

Reduced labor cost and human error in the testing process

In today’s competitive automotive landscape, these benefits can translate into fewer recalls, stronger brand reputation, and better overall performance.

Supporting Advanced Lighting Technologies

As automotive lighting evolves, so too must the testing equipment. Modern lighting systems feature adaptive lighting, daytime running light integration, and complex beam patterns, all of which require more sophisticated testing strategies.

Jinway’s testing platforms are constantly updated to accommodate the latest industry developments, ensuring our clients are ready for next-generation lighting systems.

Real-World Reliability and Global Standards

Our photometric test machines are trusted by leading OEM and Tier 1 clients—including global names such as Valeo, ZKW, Koito, and Hella. With Jinway, manufacturers can be confident their lighting products will pass global regulatory inspections and perform safely on roads worldwide.

About Jinway Technology Co., Ltd.

Founded in 2009 and based in Changzhou, China, Jinway Technology Co., Ltd. is a specialist in high-performance automation systems for the automotive lighting industry. We design, manufacture, and integrate a complete range of equipment—from assembly lines and dispensing machines to photometric testers and inspection units. Our goal is to help manufacturers achieve efficiency, consistency, and quality at every step of the production process.

Conclusion: Light the Road with Confidence

Photometric testing is not just about measuring light—it's about delivering safety, precision, and trust to every vehicle on the road. At Jinway Technology, we’re proud to empower manufacturers with the tools they need to meet the highest standards.