From Manual to Automated: How Our Solutions Upgrade Legacy Production Lines

In today's fast-paced industrial environment, manufacturers are confronted with a dilemma: stick with familiar manual processes that have worked for decades or transition to automation to meet rising expectations for speed, quality, and traceability.

Legacy production lines, while once state-of-the-art, now often struggle to meet the requirements of Industry 4.0—smart, connected, data-driven manufacturing. The pressure to stay competitive and compliant is pushing many companies to rethink how they produce.

At Jinway Technology Co., Ltd., we’re helping manufacturers embrace this shift. Our custom-designed automation equipment brings modern performance and precision to traditional lines without requiring a total overhaul. Through a structured upgrade process, we bridge the gap between legacy systems and intelligent manufacturing.

The Hidden Costs of Manual Production Lines

While manual production lines may seem cost-effective in the short term, they often come with significant limitations and inefficiencies:

Labor Intensity and Cost Volatility

As wages rise and skilled labor becomes harder to find, labor-heavy lines lose their economic edge. Additionally, reliance on human operators creates variability in performance and output.

Inconsistent Product Quality

Manual operations inherently vary from one operator to another. This leads to fluctuations in product quality, increased defect rates, and greater reliance on rework.

Limited Data Collection and Traceability

Manual systems typically lack the ability to capture production data in real time. In today’s regulated industries, traceability is critical—not only for quality assurance but for compliance and customer trust.

Slow Adaptation to Product Changes

Legacy systems can be rigid. Updating them for new product variants or designs is often time-consuming, delaying time-to-market and limiting flexibility.

Why Automation is the Future

Automation doesn’t just replace labor—it enhances precision, accelerates throughput, and enables real-time process monitoring. In short, automation amplifies what’s possible.

✔ Increased Output & Repeatability

Automated systems can run continuously with minimal supervision, ensuring a steady output and drastically reducing the variation found in manual work.

✔ Integrated Quality Assurance

Our machines come equipped with in-line sensors, vision systems, and test modules that automatically detect defects, misalignments, or missing components—ensuring quality is built into every step.

✔ Full Data Capture and Reporting

Our systems record detailed production metrics, store images and test results, and feed them into MES or ERP systems for traceability, analysis, and continuous improvement.

✔ Operator-Friendly Interfaces

Touchscreen HMIs and user-friendly software interfaces make it easy for operators to run and maintain equipment without needing extensive retraining.

Jinway Technology's Approach: How We Transform Your Line

Upgrading a production line is not a one-size-fits-all process. At Jinway, we take a consultative, collaborative approach to ensure a smooth transformation from manual to automated systems.

Step 1: On-Site Evaluation and Analysis

We begin with a deep dive into your current production process:

✅ Mapping each station and manual operation

✅ Analyzing production bottlenecks

✅ Identifying failure points, inconsistencies, and labor-intensive steps

✅ Reviewing space, utilities, and line layout

This discovery process ensures our solution is built around your goals and constraints, not the other way around.

Step 2: Modular Automation Strategy

Instead of replacing your entire line, we identify modular opportunities for automation:

✅ Replacing manual gluing with automated precision dispensing

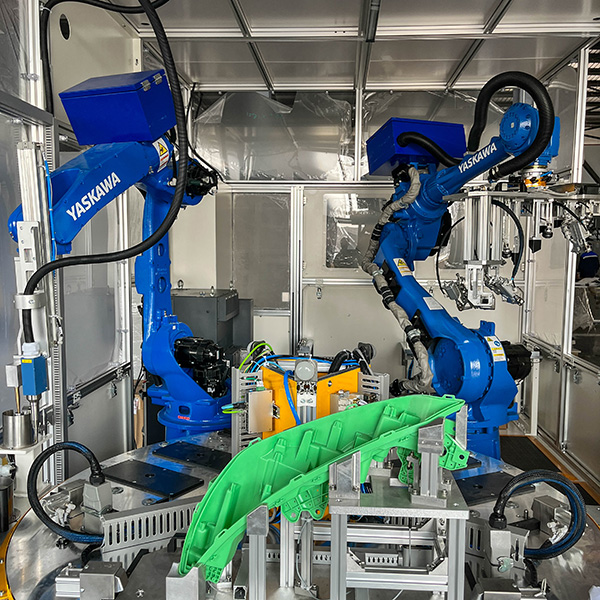

✅ Introducing robotic screwing or welding stations

✅ Adding in-line inspection cameras and sensors for quality control

✅ Integrating labeling, marking, and serialization units

✅ Installing automated test equipment (e.g., photometric test machines for automotive lights)

These modular upgrades allow for incremental transformation that minimizes downtime and capital expenditure.

Step 3: Design, Engineering, and Simulation

Our R&D and engineering team design equipment tailored to your products and processes:

✅ 2D/3D modeling and simulations

✅ Vision-guided robotics and alignment

✅ Multi-axis motion control

✅ Data interfaces for MES, barcode scanners, RFID, and more

✅ Custom fixtures and jigs for various SKUs or product families

We validate the system using digital twin simulation and rapid prototyping, ensuring performance before installation.

Step 4: Integration and Commissioning

Once ready, our automation equipment is installed, tested, and fully integrated into your line. This includes:

✅ Equipment calibration and debugging

✅ Operator training and SOP development

✅ Software integration with production databases

✅ Safety certifications and CE compliance

✅ Trial runs and fine-tuning under production conditions

Step 5: Ongoing Support and Optimization

After installation, we continue to support you with:

✅ Remote troubleshooting and diagnostics

✅ On-site service and preventive maintenance

✅ Software updates and performance monitoring

✅ Future upgrades and expansion planning

Our goal is not just to deliver a machine—but to optimize your manufacturing for the long term.

Real-World Example: Transforming a Legacy Headlamp Line

One of our clients, a regional automotive lighting manufacturer, operated a semi-manual headlamp assembly line plagued by inconsistent glue application, optical alignment failures, and a 5% rejection rate.

Jinway’s solution:

✅ A high-precision automatic gluing and curing station

✅ A smart photometric optic test machine for beam angle and intensity verification

✅ A robotic final inspection station with barcode integration and MES connection

Results:

✅ 50% faster cycle time

✅ Rejection rate reduced to <1%

✅ Improved compliance with SAE and ECE lighting standards

✅ Full traceability on every headlamp produced

The investment paid off in under 14 months, and the client has since expanded with additional Jinway systems.

Industries We Serve with Automation Solutions

While automotive lighting is our specialty, our solutions are deployed across a range of sectors:

Automotive Components: Lamps, mirrors, harnesses, modules

Consumer Electronics: PCB assembly, camera modules

Plastic Parts Manufacturing: Welding, gluing, hot riveting

Medical Devices: Small-scale precision assembly

Energy & Power: Battery pack testing, module assembly

Why Jinway Technology Co., Ltd.

✅ 15+ years of innovation in factory automation

✅ Tailor-made systems designed to fit YOUR product, not a generic template

✅ Expertise in combining mechanical engineering, optical testing, vision inspection, and software control

✅ Global presence, with equipment installed in factories across Asia, Europe, and North America

✅ Scalable, reliable, and backed by professional after-sales service

Conclusion: Turn the Page on Manual Limitations

Automation isn’t just a technology—it’s a strategy for growth, resilience, and competitiveness. At Jinway Technology, we empower manufacturers to transition from outdated methods to intelligent, efficient, and flexible production systems.