How Jinway Integrates Testing and Final Inspection Systems for Zero Defect Goals

Achieving zero defects is no longer an ambition—it is an expectation in today’s automotive manufacturing environment. As global OEMs demand higher precision, shorter lead times, and flawless product consistency, suppliers like Jinway Technology have transformed their production philosophy. At the heart of this transformation is the integration of advanced testing and final inspection systems that ensure every automotive lighting component meets rigorous quality benchmarks before it reaches the customer.

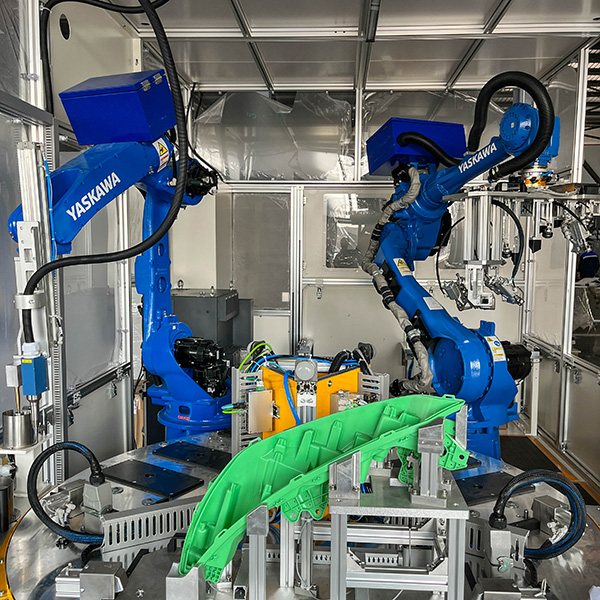

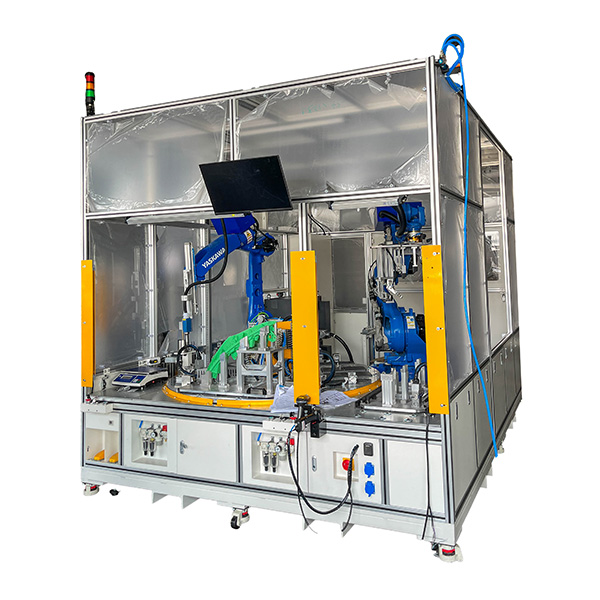

Jinway’s approach begins long before the final inspection stage. Quality assurance is built into every level of production, starting from the tooling and assembly lines to the UV coating and anti-fog processes. Each workstation is equipped with monitoring technologies that capture real-time data on critical parameters such as dimensional accuracy, coating thickness, air leakage, and alignment precision. By detecting variations early, Jinway minimizes the risk of defects progressing to later stages, significantly reducing rework and waste. One of the core strengths of Jinway’s system lies in the harmonization of mechanical, electronic, and optical testing capabilities. Automated photometric inspection machines verify light distribution patterns, brightness levels, and color temperatures to ensure global automotive lighting standards are met. Vision inspection systems detect micro-defects such as surface blemishes, dust inclusions, and irregular coatings that the human eye may overlook. These automated inspections eliminate subjective judgment and ensure every product adheres to consistent quality criteria.

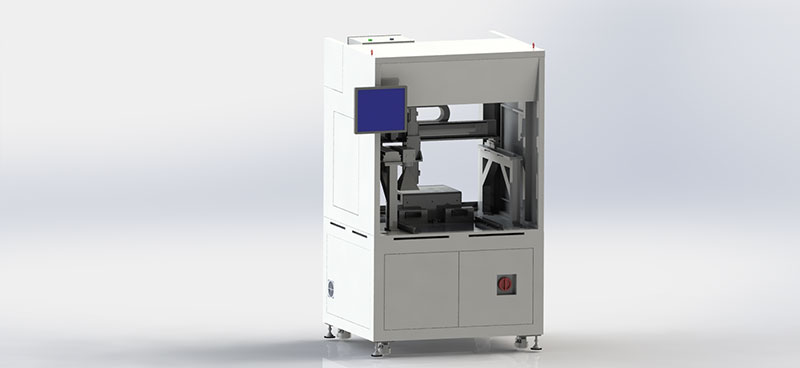

Also important is Jinway’s integration of air leakage testing and final sealing checks, crucial for ensuring long-term reliability of headlamps and tail lamps. Advanced pressure sensors and digital monitoring platforms ensure that each unit maintains its structural integrity under varying environmental conditions. With high sensitivity and high repeatability, these systems guarantee that no moisture or dust can infiltrate the lighting components during their service life. In the final assembly stage, Jinway combines automated inspection stations with detailed manual verification to ensure complete reliability. This includes engraving systems that mark each unit with traceable identifiers, allowing full tracking from raw materials to finished products. Traceability is central to Jinway’s zero-defect goals, ensuring that any deviation can be quickly traced back to its root cause and corrected without delay.

Data plays a critical role in Jinway’s quality ecosystem. All testing and inspection systems are linked to a centralized digital management platform that records performance metrics, inspection results, and production trends. This continuous stream of data allows Jinway’s engineering team to identify patterns, optimize processes, and implement preventive measures. Instead of reacting to defects, the company predicts and prevents them through statistical analysis and real-time decision-making. Ultimately, Jinway’s integration of testing and final inspection systems reflects its commitment to delivering world-class automotive lighting solutions. By combining automation, intelligent monitoring, and traceable quality control processes, the company ensures each product maintains flawless performance and long service life. Achieving zero defects is not just a goal—it is woven into Jinway’s manufacturing culture, enabling the company to build lasting trust with global automotive OEMs.