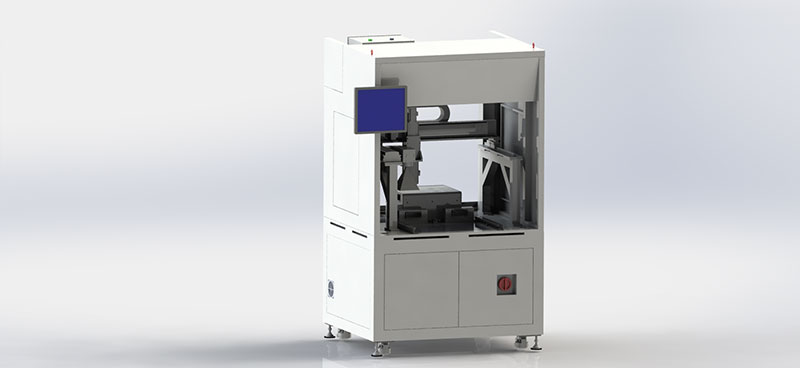

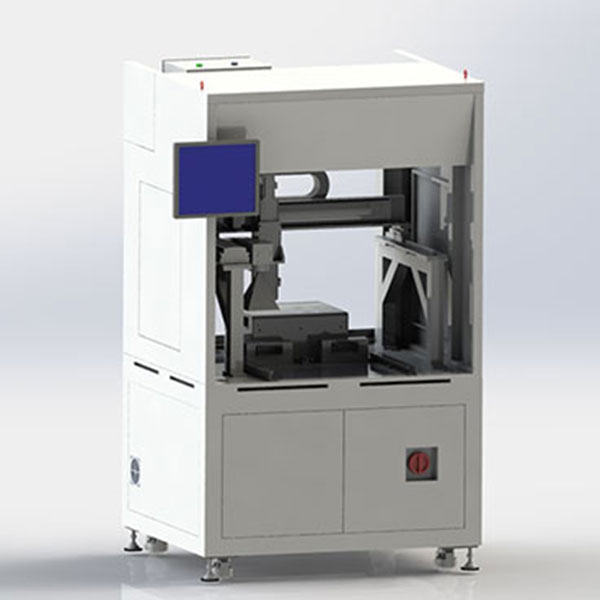

Hybrid Testing Platforms: Combining Mechanical, Optical, and AI Systems

In the modern manufacturing environment, quality assurance is no longer a one-dimensional task. Products today are more complex, customer expectations are higher, and industry standards are stricter. To meet these demands, hybrid testing platforms have emerged as a powerful solution. By combining mechanical testing, optical inspection, and artificial intelligence (AI) systems, manufacturers can achieve a level of precision and reliability that single-method approaches cannot deliver.

Traditional testing relied heavily on mechanical or optical systems in isolation. Mechanical testing provided durability and stress insights, while optical inspection ensured visual quality. However, as product complexity grew—especially in sectors like automotive, aerospace, and electronics—these standalone approaches often proved insufficient. The introduction of AI into this landscape has created an integrated testing ecosystem capable of addressing multiple dimensions of product performance simultaneously.

Mechanical testing remains essential in validating structural integrity and functional performance. Whether it is measuring stress resistance in automotive components or endurance in aerospace parts, these tests ensure that products can withstand real-world conditions. When integrated into a hybrid platform, mechanical testing data can be correlated with optical and AI insights to provide a complete picture of product behavior.

Optical systems add another critical layer of precision. Photometric, spectrometric, and imaging technologies can identify surface defects, color inconsistencies, and alignment errors with unmatched accuracy. Unlike human inspectors, optical systems do not tire, and they offer repeatable, objective measurements. In a hybrid setup, optical inspection complements mechanical testing by catching defects that stress testing alone would miss.

Artificial intelligence transforms hybrid testing platforms from static systems into adaptive solutions. AI algorithms analyze vast streams of data from both mechanical and optical systems, identifying patterns, predicting failures, and continuously improving accuracy. With machine learning, these platforms can adapt to new product designs or process variations without extensive reprogramming. This flexibility makes hybrid systems future-proof in fast-changing industries.

The true value of hybrid testing lies in integration. Mechanical stress data, optical defect detection, and AI-driven analytics are combined into a single platform that delivers real-time insights. Instead of waiting for end-of-line inspections, manufacturers can monitor product quality continuously and intervene early when anomalies are detected. This closed-loop approach reduces waste, improves efficiency, and enhances overall reliability.

Hybrid testing platforms are finding applications across a wide range of industries. In automotive manufacturing, they ensure headlights meet both structural and optical performance standards while predicting long-term reliability. In electronics, they verify solder joint strength, surface alignment, and circuit board integrity. Aerospace manufacturers rely on hybrid platforms to confirm both material durability and flawless finishes. Even emerging fields like renewable energy and smart devices benefit from this comprehensive testing approach.

By combining mechanical, optical, and AI systems, hybrid testing platforms move manufacturers closer to the goal of zero-defect production. Instead of reactive quality control, these platforms enable proactive quality assurance, catching errors before they escalate into costly recalls or warranty claims. They also provide traceable data records, helping companies meet regulatory requirements and customer demands for transparency.

Hybrid testing platforms represent the next evolution in manufacturing quality assurance. By uniting the strengths of mechanical durability testing, optical precision, and AI intelligence, these systems deliver insights that no single method could achieve alone. As industries grow more complex and competitive, hybrid testing will play a central role in ensuring safety, reliability, and customer satisfaction.