Inside Jinway’s UV Coating Line Where Performance Meets Perfection

In the world of automotive lighting, surface quality is just as important as internal engineering. Headlamps, taillights, and other lighting components must deliver clear, consistent illumination while maintaining a flawless appearance under some of the harshest environmental conditions. Achieving this level of performance requires more than advanced materials alone—it demands cutting-edge surface treatment technology. At Jinway Technology Co., Ltd., the UV coating line represents the point where engineering precision meets aesthetic excellence, ensuring each lighting component reaches its highest potential.

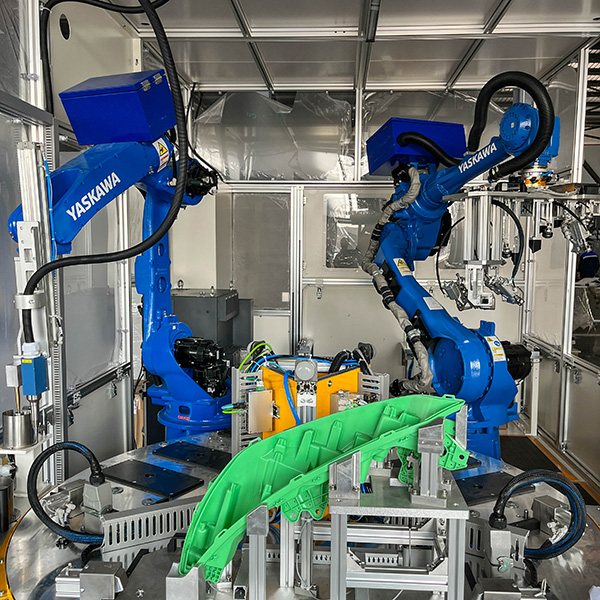

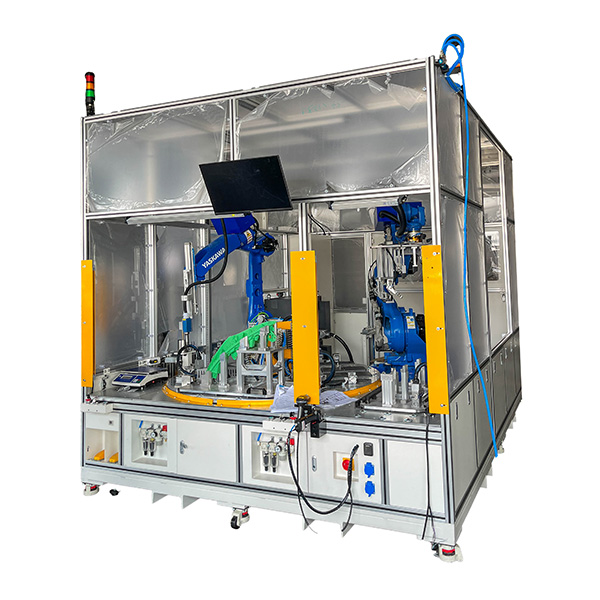

From the outside, a UV coating line may seem like just another part of an industrial production facility. Inside, however, it is a carefully controlled environment where temperature, airflow, coating thickness, and curing intensity are constantly monitored. Every stage is designed to eliminate defects and maximize consistency. The result is a durable, crystal-clear surface that enhances both the functionality and the visual appeal of automotive lighting components. The process begins with meticulous surface preparation. Before any coating can be applied, each lens or lighting component must be perfectly clean. Even microscopic dust particles or oil traces can affect adhesion and final appearance. Jinway integrates advanced cleaning systems into its UV coating line to remove contaminants, using a combination of air treatment, washing, and drying processes. This ensures that every surface entering the coating stage is flawlessly prepared for optimal results.

Next comes the coating application itself, where precision is everything. A specialized UV-curable coating is uniformly applied across the surface of the component using highly controlled spraying or flow-coating methods. The thickness of this layer is carefully regulated to provide maximum protection without distorting optical performance. A layer that is too thin may offer insufficient protection, while a layer that is too thick can reduce light transmission and clarity. Jinway’s automated coating systems maintain an ideal balance, producing a smooth, even finish on every piece. Once applied, the coating is instantly cured using high-intensity ultraviolet light. This curing process is one of the key advantages of UV coating technology. Unlike traditional thermal drying, which can take significant time and energy, UV curing hardens the coating in seconds. This not only increases production efficiency but also creates a harder, more durable surface. The cured coating offers excellent resistance to scratches, chemicals, and UV radiation, which helps prevent yellowing, fading, and degradation over time.

In partnership with Wenton, Jinway’s UV coating lines and ovens are designed to integrate seamlessly into larger automotive lighting production systems. This integration allows for a smooth, continuous workflow, minimizing downtime and maximizing output. At the same time, intelligent monitoring systems track each stage of the process, ensuring consistent quality from the first component to the last. Any deviation in parameters such as temperature or curing intensity is immediately detected and corrected, guaranteeing a stable and repeatable outcome. Performance is only part of the story. Aesthetics play an equally vital role in modern automotive design. Vehicle manufacturers rely on clear, glossy, and visually flawless lighting components to enhance brand image and overall vehicle design. The UV coating applied on Jinway’s lines delivers a premium, high-gloss finish that meets the strict aesthetic requirements of today’s automotive brands. It enhances surface smoothness, improves light transmission, and gives headlamps and taillights a refined, high-end appearance.

Beyond visual appeal and durability, Jinway’s UV coating technology also supports more sustainable manufacturing practices. UV-curable materials typically contain fewer volatile organic compounds (VOCs) compared to traditional solvent-based coatings. Combined with the energy efficiency of UV curing, this significantly reduces the environmental impact of the coating process. By adopting cleaner and more efficient technology, Jinway helps its OEM partners achieve their sustainability goals without compromising quality. Ultimately, Jinway’s UV coating line is more than just a piece of equipment—it is a symbol of the company’s dedication to innovation, precision, and excellence. Guided by a strong technical team and supported by trusted partners, Jinway continues to refine its processes, improve efficiency, and deliver outstanding results to customers around the world. Inside Jinway’s UV coating line, performance truly meets perfection. Every component that passes through it reflects a commitment to quality, a focus on detail, and a clear vision for the future of automotive lighting manufacturing.