Lighting the Future: Trends in Automotive Lighting and Testing Technology

Automotive lighting has evolved from a simple utility to a defining element of both vehicle safety and brand identity. As modern vehicles become smarter, sleeker, and more safety-conscious, lighting systems are transforming to keep pace. From adaptive beam control to dynamic turn signals, today's headlights are not just brighter—they're intelligent. Alongside this evolution, testing technologies have also advanced. At Jinway Technology Co., Ltd., we play a pivotal role in this transition by providing high-precision photometric and optical test equipment that ensures every lamp meets exacting performance and regulatory standards.

Trend 1: The Rise of LED and Laser Headlamps

One of the most dominant trends in recent years is the shift from halogen and HID lamps to LED and laser headlamps. These technologies offer numerous benefits: energy efficiency, longer lifespan, compact size, and the flexibility to create unique design shapes. However, they also introduce new testing challenges. LED arrays must be tested for uniformity, color temperature, and beam pattern precision, all of which are critical for visibility and safety. Jinway’s advanced photometric testing systems are specially designed to measure these parameters with high-speed, high-resolution accuracy.

Trend 2: Adaptive Lighting and ADB Technology

Adaptive Driving Beam (ADB) technology is revolutionizing night driving. By automatically adjusting light distribution based on traffic and road conditions, ADB systems increase visibility while avoiding glare for other drivers. These systems require complex control algorithms and precise alignment of LED segments. Jinway’s optical test benches and goniophotometers allow manufacturers to validate adaptive functions by simulating real-world road scenarios and recording dynamic light behavior in controlled environments.

Trend 3: Integration with Advanced Driver Assistance Systems (ADAS)

Modern headlamps are now part of the vehicle’s ADAS ecosystem, integrating with cameras, sensors, and control units. Lighting is no longer isolated—it must respond intelligently to input from external systems. This requires not only functional validation of the lamp itself but also communication testing, signal response accuracy, and data synchronization. Jinway supports OEMs and Tier 1 suppliers with testing systems capable of evaluating both light output and electronic response, ensuring full system compatibility.

Trend 4: Style Meets Function—The Aesthetic Revolution

From sweeping DRLs (Daytime Running Lights) to sequential turn signals and logo projections, lighting is now a core part of vehicle aesthetics. Automakers use it to express brand identity and product differentiation. With more emphasis on design complexity, the need for precision testing grows. Light diffusion, edge clarity, and even color rendering are now critical quality metrics. Jinway’s integrating sphere systems and colorimetric test stations help manufacturers validate not just safety parameters, but design integrity.

Trend 5: Regulatory Compliance Becomes More Complex

As lighting technology advances, global regulations are evolving to keep pace. Standards from organizations like ECE (Europe), SAE (USA), and GB (China) are being updated to address adaptive lighting, color tolerances, and glare prevention. For manufacturers, keeping up with these changes can be a major challenge. Jinway’s test systems are developed with multi-standard compatibility, allowing manufacturers to test against different regional benchmarks within the same test setup. This ensures faster certification, reduced rework, and smooth international deployment.

The Role of Testing Technology in Innovation

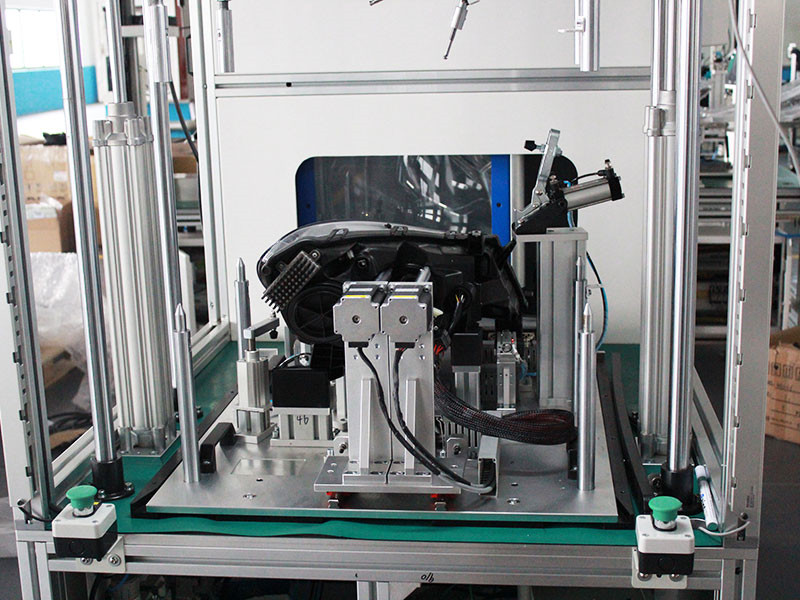

Innovation in lighting cannot thrive without equally advanced testing systems. As lamps become more intelligent and intricate, manufacturers must rely on highly automated, high-precision test equipment to maintain safety, performance, and consistency.

At Jinway Technology, we invest heavily in R&D to ensure our machines match the pace of innovation. From fully automated photometric test lines to modular optical inspection units, our solutions are designed to:

Validate light output, distribution, and intensity

Measure beam pattern conformity in real-time

Provide colorimetric and spectrophotometric data

Interface with MES systems for traceability and analytics

What Sets Jinway Technology Apart

With over 15 years of industry experience, Jinway Technology is a trusted partner for automotive lighting manufacturers around the world. Our test solutions are:

Customized to match your specific lamp architecture and testing needs

Compliant with global regulatory standards

Smart-factory ready, with data integration and remote diagnostics

Built for efficiency, with automation that reduces test time and human error

Whether you’re producing standard headlights, ADB systems, or decorative lighting modules, we offer scalable, future-ready solutions to ensure your products light the way—safely and brilliantly.

Conclusion: Lighting the Road Ahead

The future of automotive lighting is bright—both literally and figuratively. As design, safety, and intelligence converge, the demands on testing systems will only grow more complex. At Jinway Technology Co., Ltd., we are committed to staying at the forefront of this transformation.

Our mission is to support manufacturers in delivering lighting solutions that are not just compliant, but cutting-edge. Through innovation, precision, and partnership, we help you shape the future—one beam of light at a time.