Managing Optical Tolerances in Projector Lens Manufacturing

In modern automotive lighting systems, projector lenses play a crucial role in shaping light distribution, controlling glare, and delivering precise beam patterns. As vehicle safety standards become stricter and lighting designs more sophisticated, managing optical tolerances in projector lens manufacturing has become one of the most critical challenges in the industry. Even the smallest deviation in lens geometry or alignment can significantly affect lighting performance and regulatory compliance. Optical tolerance refers to the allowable variation in lens dimensions, surface accuracy, curvature, and positioning that still ensures acceptable optical performance. In projector lens manufacturing, these tolerances are often measured in microns. Slight inconsistencies in radius, thickness, or concentricity can lead to beam distortion, blurred cutoff lines, or uneven illumination on the road. For this reason, tolerance control must be addressed from the earliest design stage through to final inspection.

The foundation of effective tolerance management begins with precision tooling. High-quality molds and machining tools are essential to produce lenses with consistent geometry and surface finish. Advanced CNC machining and ultra-precision mold manufacturing help ensure that each lens meets exact design specifications. Stable tooling not only improves dimensional accuracy but also reduces variation across large production batches, supporting long-term consistency in mass manufacturing. Material selection is another key factor in managing optical tolerances. Optical-grade plastics and glass materials must offer excellent dimensional stability, low birefringence, and predictable behavior during molding or forming. Variations in material flow, shrinkage, or cooling can introduce subtle distortions that affect optical performance. Careful material qualification and process parameter control are therefore essential to minimize these risks.

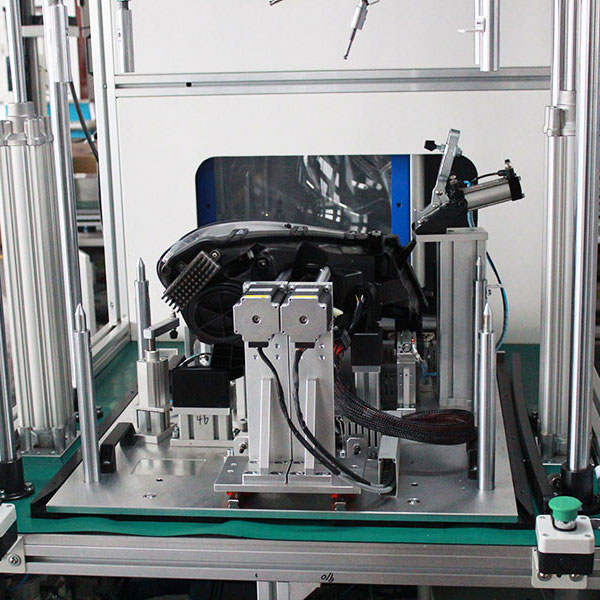

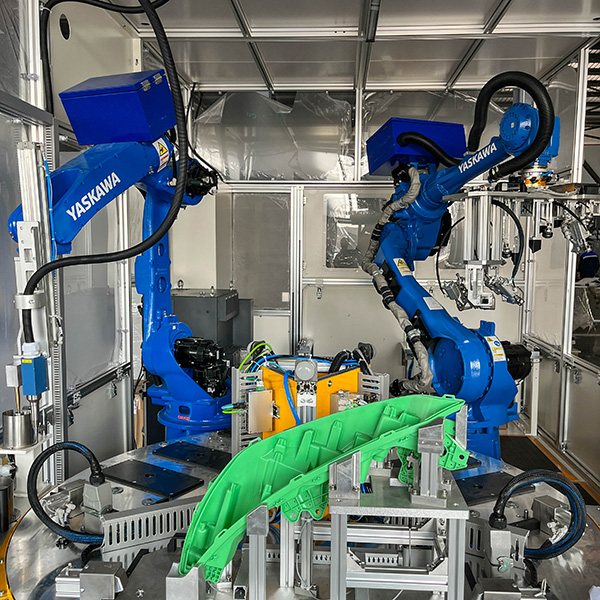

During production, process control plays a vital role in maintaining tight tolerances. Injection molding temperature, pressure, cooling time, and mold alignment must be precisely controlled to avoid warpage or internal stress. Automated production systems help maintain consistency by reducing human error and ensuring repeatable manufacturing conditions. In high-volume automotive lighting projects, this level of control is critical to meeting OEM quality expectations. Equally important is the alignment of projector lenses within the lighting assembly. Even a perfectly manufactured lens can fail to perform correctly if it is misaligned during assembly. Precision assembly lines, accurate positioning fixtures, and real-time monitoring systems help ensure correct lens placement relative to light sources and reflectors. This integration between lens manufacturing and assembly is essential for achieving stable beam patterns.

Testing and inspection provide the final assurance that optical tolerances are being maintained. Advanced photometric testing systems and optical measurement tools are used to evaluate beam shape, cutoff accuracy, and light distribution. By analyzing real performance data, manufacturers can quickly identify tolerance-related issues and make process adjustments before defects reach the market. At Jinway Technology, managing optical tolerances is treated as a system-level responsibility rather than a single production step. Through precision tooling, controlled manufacturing processes, automated assembly lines, and integrated photometric testing, Jinway supports OEM customers in achieving consistent, compliant, and high-performance projector lens systems. This comprehensive approach reduces rework, shortens development cycles, and enhances overall product reliability.

As automotive lighting continues to evolve toward higher precision and smarter functionality, tolerance management will remain a defining factor of manufacturing excellence. By mastering optical tolerances in projector lens production, manufacturers can ensure superior lighting performance, regulatory compliance, and long-term customer trust in an increasingly demanding global market.