Managing Thermal Stability in High-Precision Photometric Systems

In the world of high-precision photometric testing, temperature control plays a crucial but often underestimated role. Managing thermal stability is not simply about keeping systems cool—it’s about ensuring that light measurements remain accurate and repeatable over time. Even small temperature changes can cause optical misalignments, sensor drift, and inconsistent readings, all of which compromise the reliability of test results. As industries like automotive, aerospace, and electronics demand increasingly tight quality standards, maintaining thermal stability in photometric systems has become essential for guaranteeing consistent performance and compliance.

Photometric testing involves measuring the intensity, distribution, and color of light with exceptional accuracy. However, these measurements are extremely sensitive to temperature variations. Light sources such as LEDs and halogen lamps exhibit thermal-dependent behavior—brightness and color can shift as the junction temperature changes. Detectors, including CCD and CMOS sensors, also show increased noise levels when their internal temperature rises. Mechanical components such as mounts or lenses expand slightly with heat, causing alignment shifts that can alter the optical path. All of these effects, though small, can combine to create large measurement deviations if thermal conditions are not properly managed.

Thermal instability in photometric systems originates from several sources. High-power light sources generate substantial heat during testing, especially when operated continuously. Detectors, amplifiers, and control electronics dissipate energy as heat during data processing. Even external factors such as room temperature changes or airflow from nearby equipment can affect the testing environment. When combined, these heat sources create complex temperature gradients that can distort measurements if not carefully controlled. Understanding and mitigating these influences is the first step toward achieving consistent results.

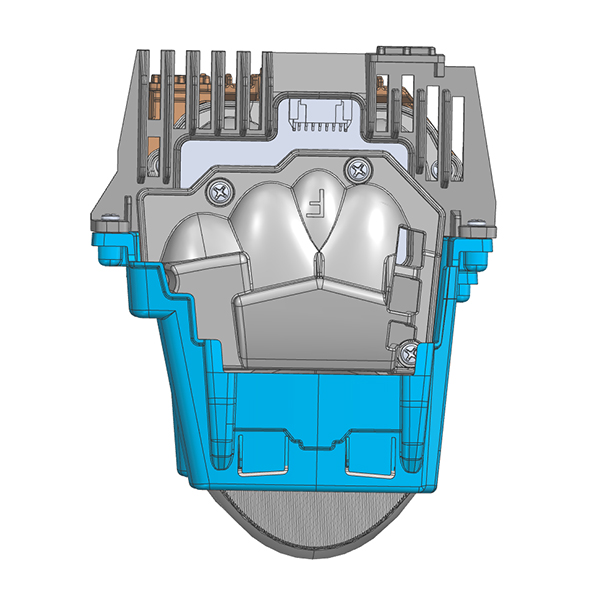

The foundation of thermal management begins with mechanical and material design. Engineers select materials with low thermal expansion rates—such as Invar, stainless steel, or carbon fiber composites—to build optical mounts and support structures. These materials resist dimensional changes when heated, preserving precise optical alignment. Components are often thermally isolated from one another to prevent heat transfer between sensitive elements like light sources and detectors. In addition, airflow paths are designed to avoid introducing turbulence that could destabilize light beams or cause uneven cooling.

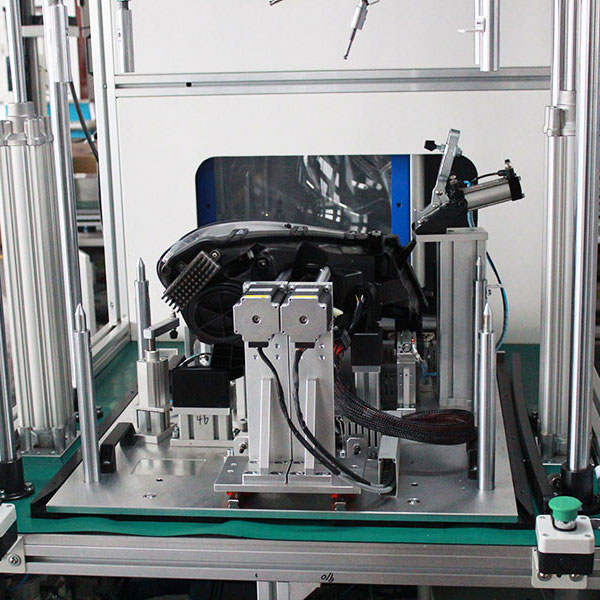

While passive design strategies are essential, modern photometric systems rely on active temperature control to maintain stable conditions during testing. Thermoelectric coolers (Peltier devices) are frequently used to stabilize sensor temperatures within a fraction of a degree. High-power light sources may require liquid or air cooling systems to manage heat buildup. Temperature control units equipped with PID (Proportional-Integral-Derivative) controllers monitor and adjust temperature in real time, ensuring that each test is conducted under consistent conditions. These active control systems form a closed thermal loop, maintaining stability even when environmental conditions fluctuate.

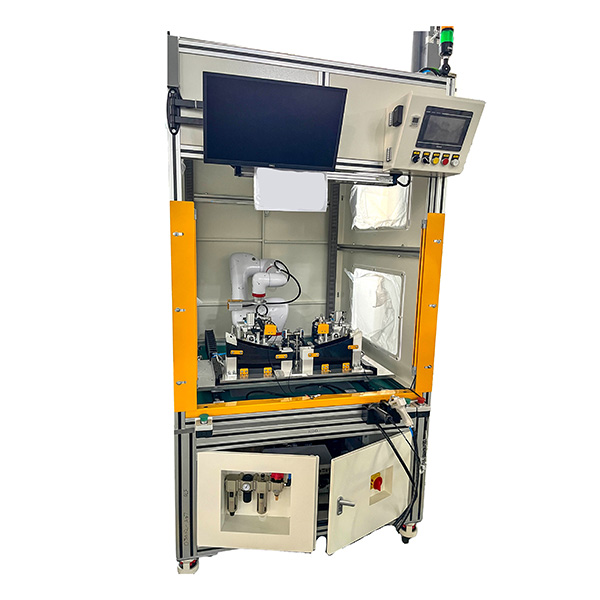

To further improve consistency, many high-end photometric test systems are placed inside temperature-controlled enclosures. These chambers create an isolated microenvironment, shielding the system from external variations such as room temperature swings, humidity changes, and vibrations. Within the enclosure, integrated climate systems regulate both temperature and humidity to keep the optical and electronic components operating within optimal limits. This approach allows manufacturers to reproduce identical testing conditions across multiple sessions, which is essential for traceable and repeatable measurements.

Even the best thermal designs require regular calibration to ensure accuracy. Photometric systems undergo calibration cycles that establish how performance varies with temperature. By testing reference light sources under controlled thermal conditions, engineers can generate correction curves that compensate for temperature-induced shifts. During actual testing, the control software automatically applies these compensation values, maintaining accuracy regardless of small temperature fluctuations. Regular calibration ensures long-term measurement reliability and helps detect early signs of thermal drift.

Modern photometric testing equipment integrates real-time thermal monitoring to provide immediate feedback on system conditions. Sensors embedded throughout the system continuously measure component temperatures and relay the data to control algorithms. When the system detects deviations, it automatically adjusts cooling or heating output to restore balance. In advanced setups, temperature data is logged over time, allowing engineers to analyze patterns and improve future designs. Some systems even use thermal imaging during maintenance to locate heat buildup areas that could affect accuracy or reliability.

When thermal stability is neglected, measurement accuracy quickly degrades. LEDs under test may produce misleading brightness data as their internal temperature changes, while color shifts can distort chromaticity and uniformity results. Sensors may register false readings due to noise fluctuations, and optical alignments can drift out of tolerance. Over time, these errors not only reduce product quality but also increase testing downtime due to frequent recalibrations or equipment wear. Consistent thermal management prevents these problems, maintaining both the precision and efficiency of the entire testing process.

As automation and digitalization evolve, thermal management is also becoming smarter. Artificial intelligence and machine learning algorithms are now being used to predict temperature variations based on historical performance data. These systems can make proactive adjustments to cooling or heating before a drift occurs, maintaining stability without human intervention. Combined with cloud-based monitoring and remote diagnostics, AI-driven control ensures maximum reliability while minimizing maintenance requirements. This level of intelligence represents the future of thermal stability management in precision photometry.

Managing thermal stability in high-precision photometric systems is not just an engineering challenge—it is a fundamental requirement for measurement accuracy. Every component, from light sources to detectors, depends on a stable thermal environment to deliver trustworthy results. Through a combination of smart design, active temperature control, environmental isolation, and advanced monitoring, manufacturers can achieve the consistency needed for modern testing standards. As photometric technology continues to advance, particularly in automotive and aerospace applications, maintaining precise thermal balance will remain a key factor in ensuring quality, reliability, and long-term system performance.