Polycarbonate vs. Other Plastics: Why Polycarbonate is the Material of Choice for Automotive Lenses

In the world of automotive manufacturing, the materials used for critical components such as headlamps can significantly affect vehicle performance, safety, and longevity. One material that stands out for its use in automotive lenses is polycarbonate (PC). While there are several plastic materials available for automotive applications, polycarbonate continues to be the material of choice for headlamps and other lighting lenses. But what makes polycarbonate so desirable compared to other plastics? Let’s explore the reasons why polycarbonate is the material of choice for automotive lenses and how it outperforms its plastic counterparts.

1. Exceptional Impact Resistance

When it comes to automotive lenses, impact resistance is a non-negotiable requirement. Headlamp lenses are exposed to numerous potential hazards, including road debris, gravel, stones, and even collisions with other vehicles. Without adequate protection, lenses could crack or shatter, impairing the functionality of the vehicle's lighting system and posing safety risks.

Polycarbonate stands out because of its exceptional impact resistance. Compared to other plastics, such as acrylic or polypropylene, polycarbonate is significantly tougher and more resistant to cracking or breaking upon impact. This resilience makes polycarbonate ideal for use in automotive lenses, where durability is crucial to ensuring safety during driving. For instance, polycarbonate is 250 times more impact-resistant than glass, making it the preferred material for automotive applications where the lens must endure high-impact conditions, such as when debris strikes the headlamp during high-speed driving.

2. Optical Clarity and Light Transmission

In addition to being tough and impact-resistant, automotive lenses must also offer high optical clarity to ensure proper light transmission. The ability of a headlamp lens to transmit light efficiently is vital for providing clear and bright illumination, particularly at night or during adverse weather conditions.

Polycarbonate is an excellent material for automotive lenses because it offers high light transmittance, typically greater than 85%. This ensures that headlights maintain their full brightness, even after prolonged exposure to UV radiation, dirt, and weathering. While materials like acrylic and polymethyl methacrylate (PMMA) also have high light transmittance, polycarbonate excels in combining optical clarity with impact resistance, making it a superior choice for automotive lighting applications.

3. Lightweight Nature

Another key consideration for automotive manufacturing is weight reduction. Lighter vehicles lead to improved fuel efficiency, better handling, and increased overall performance. Polycarbonate offers a significant advantage over traditional glass and some other plastics due to its lightweight nature.

While glass is heavier and more prone to breakage, polycarbonate is much lighter, which is particularly advantageous when designing automotive lenses. The reduced weight helps car manufacturers achieve better performance, fuel efficiency, and ease of installation without compromising on strength or durability. Polycarbonate’s light weight is a key factor in the automotive industry’s trend toward weight-saving technologies, making it an essential material for modern vehicles that require robust yet lightweight components.

4. UV Resistance and Weatherability

Automotive lenses are subjected to a wide range of weather conditions, from intense sunlight to snow, rain, and sleet. Over time, exposure to UV rays can cause plastic materials to degrade, become brittle, yellow, or lose their clarity. This deterioration can significantly affect the lens's performance and aesthetic appeal.

Polycarbonate, while prone to UV degradation without proper treatment, can be easily coated with UV-protective layers to enhance its weatherability. This coating helps prevent the lens from yellowing or becoming cloudy over time, ensuring that the headlamps retain their transparency and functionality for the life of the vehicle. Compared to other plastics like acrylic, polycarbonate’s ability to be effectively treated for UV resistance makes it a more durable and longer-lasting solution for automotive lenses. Even when exposed to prolonged UV radiation, polycarbonate lenses maintain their clarity and optical performance.

5. Ease of Molding and Design Flexibility

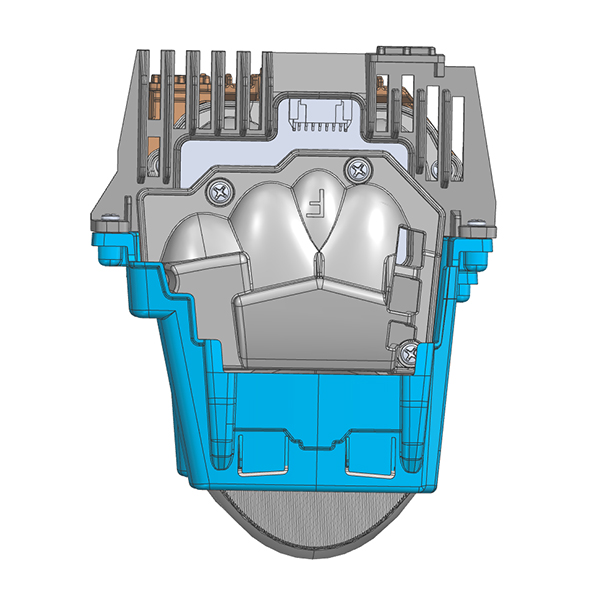

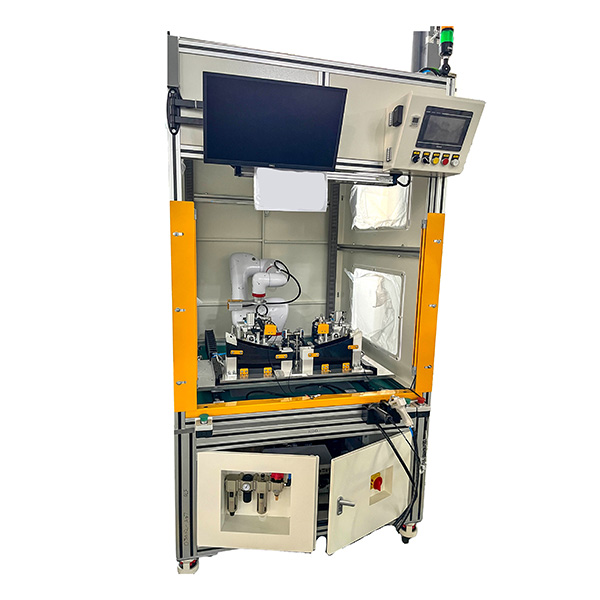

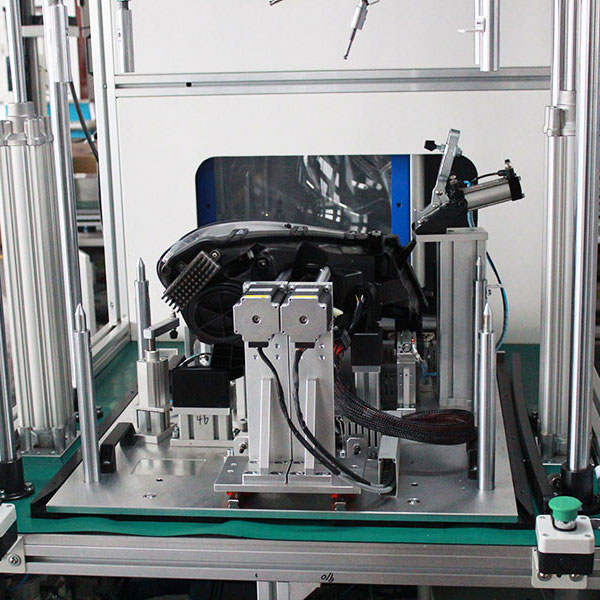

Automotive headlamps often feature complex designs that require precise molding and shaping. Polycarbonate excels in thermoplastic molding, which allows manufacturers to create intricate, customized shapes with ease. This flexibility in design makes polycarbonate ideal for a wide range of automotive lighting applications.

In contrast, materials like acrylic or glass require more challenging and costly manufacturing processes, which can limit design options or increase production time and costs. Polycarbonate, on the other hand, is easy to mold, enabling manufacturers to create headlamp lenses with complex geometries or unique shapes without adding excessive costs. Polycarbonate’s design flexibility is especially valuable for modern automotive trends, which often demand sleek, aerodynamic, and futuristic designs for headlights.

6. Cost-Effectiveness

While polycarbonate can be more expensive than some other plastics, the combination of its durability, optical clarity, impact resistance, and design flexibility often makes it a more cost-effective choice in the long run. The durability of polycarbonate lenses means that they require fewer replacements and repairs, saving on both material and labor costs.

Additionally, the ease of molding polycarbonate reduces manufacturing time, making it more efficient to produce automotive lenses. In comparison, materials like glass or acrylic may involve more complex production processes and higher material costs, making them less competitive for large-scale automotive production.

7. Environmental Considerations

As the automotive industry increasingly focuses on sustainability and reducing environmental impact, the choice of materials is more important than ever. Polycarbonate, being a highly durable material, contributes to the overall longevity of automotive parts, reducing the need for replacements and waste generation. Moreover, polycarbonate is recyclable and can be reused in other applications, supporting the industry’s shift toward more sustainable practices.

Conclusion:

When it comes to selecting the best material for automotive lenses, polycarbonate continues to stand out as the superior choice. Its combination of impact resistance, optical clarity, UV protection, lightweight nature, and design flexibility makes it the ideal material for headlamp lenses that need to perform under extreme conditions.