Precision Dispensing Technology in Automotive Lighting Sealing Applications

Precision dispensing technology has become essential in modern automotive lighting, where sealing quality directly influences durability, safety, and long-term visual performance. As lighting systems evolve—with LED modules, adaptive beams, and intricate internal assemblies—manufacturers face increasing pressure to maintain airtight, moisture-free environments inside each lamp. Precision dispensing ensures that the sealant is applied exactly where needed, in the correct volume, and with consistent quality throughout every production cycle. Automotive headlamps and tail lamps are exposed to harsh conditions including rain, dust, UV radiation, road debris, and constant temperature fluctuations. Even a microscopic leak can allow moisture to enter the lamp body, resulting in fogging, corrosion, and premature LED failure. The goal of precision dispensing is to create a uniform, continuous seal barrier that prevents contaminants from breaching the housing. Manual sealing, once common in older manufacturing environments, simply cannot match the consistency required for today’s high-specification lighting systems.

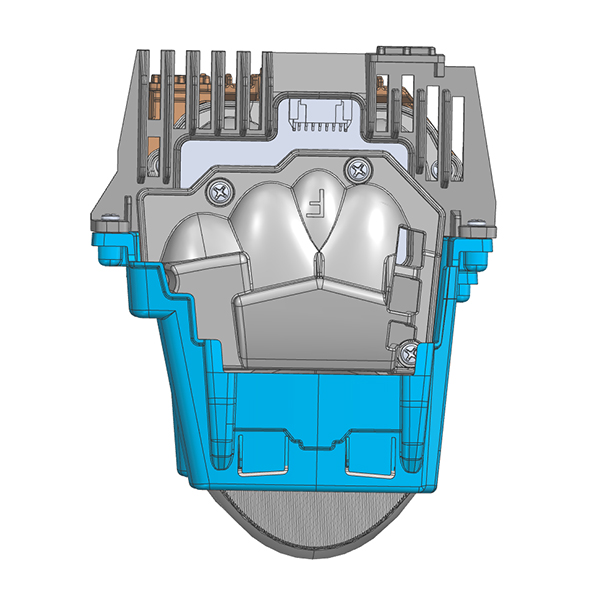

Accuracy in sealant application is critical because too little sealant may create gaps, while too much can overflow into optical zones, wiring paths, or mounting interfaces. Overflow not only wastes materials but can also interfere with light projection or require rework. Precision dispensing equipment controls bead size, width, and volume at every point along the lamp geometry. This level of control supports more elegant lamp designs, thinner housing profiles, and lightweight assemblies that demand tighter tolerances. Lighting assemblies today incorporate multi-material interfaces such as plastics, metals, and coated surfaces, each with its own adhesion requirements. Precision dispensing systems accommodate different sealant chemistries—silicones, polyurethanes, and UV-curable adhesives—allowing manufacturers to match material characteristics to performance needs. High-temperature LED environments may require sealants engineered to resist thermal expansion, while housings meant for off-road or heavy-duty vehicles demand increased chemical and vibration resistance.

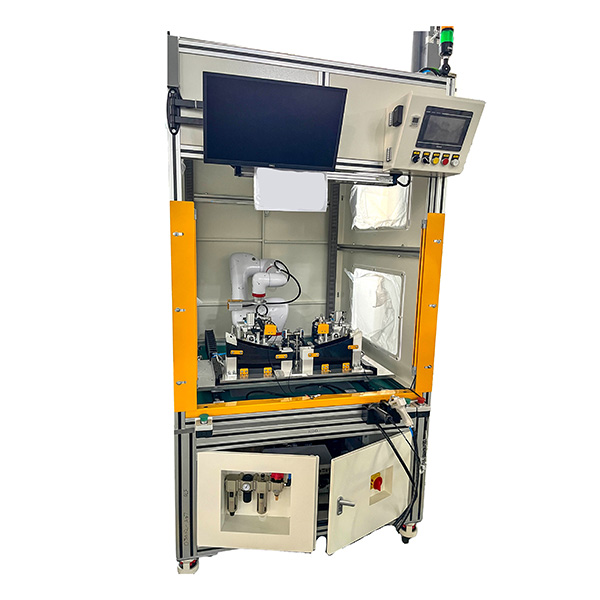

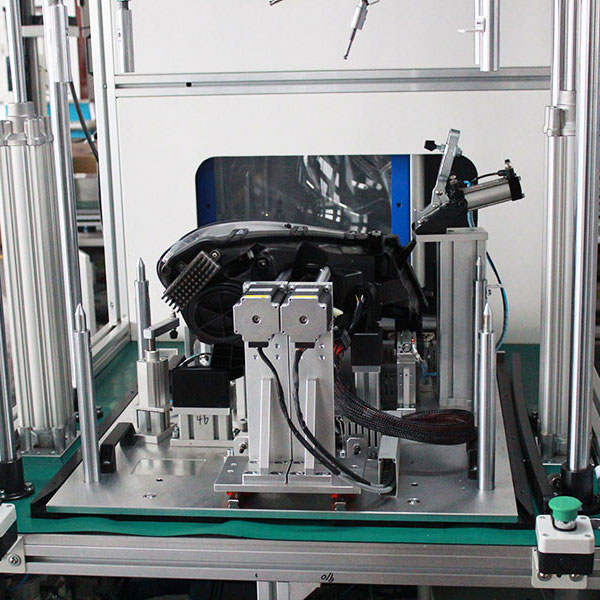

Automation plays a central role in advanced dispensing processes. Robotic dispensing arms follow pre-programmed paths tailored to each lamp shape, eliminating variability caused by human factors. Motion control, nozzle pressure, and dispensing speed are synchronized to maintain seamless application even along corners, grooves, or uneven surfaces. Machine vision systems are increasingly used to guide robots, detect gaps, and ensure that each lamp receives the correct sealing before final assembly or curing takes place. In addition to accuracy, precision dispensing improves production efficiency. Automated systems enable continuous output, reduce cycle time, and minimize downtime associated with material changeovers or manual adjustment. Real-time monitoring and sensor feedback ensure that viscosity changes—caused by temperature, humidity, or aging material—do not compromise seal quality. This reduces scrap rates and extends production stability, particularly during long manufacturing runs.

Quality assurance is another critical advantage. Precision dispensing technology allows for standardized process metrics that can be measured, recorded, and reviewed for audits or customer requirements. Data logging systems track bead diameter, flow rate, curing cycle timing, and other parameters. This digital traceability is vital in the automotive industry, where each component must meet rigorous OEM and supplier quality standards. Stable dispensing performance strengthens compliance with ISO/TS guidelines and other global certifications. As automotive lighting transitions further into LED and smart systems, internal components become more sensitive to environmental stress. Sealing not only protects electronics but also maintains optical clarity by preventing condensation. Precision dispensing enables rugged performance without increasing design complexity or adding excess material cost. It has become indispensable for supporting advanced thermal management systems and modular lamp construction.

Ongoing innovation continues to push the industry forward. Emerging technologies include AI-assisted bead path optimization, sensors that detect incomplete seals, and dispensing systems that adjust automatically for variation in parts or sealant batches. Manufacturers that invest in these capabilities are better positioned to deliver lighting systems that meet modern consumer expectations for style, longevity, and reliability. In today’s competitive automotive landscape, precision dispensing is no longer just a support function—it is a core manufacturing capability that defines product performance. By combining automated equipment, skilled engineering, proper sealant selection, and rigorous quality control, precision dispensing ensures that every lighting system remains sealed, protected, and dependable throughout the vehicle’s lifespan.