Precision Mechatronics: Where Mechanics, Optics, and Control Systems Meet

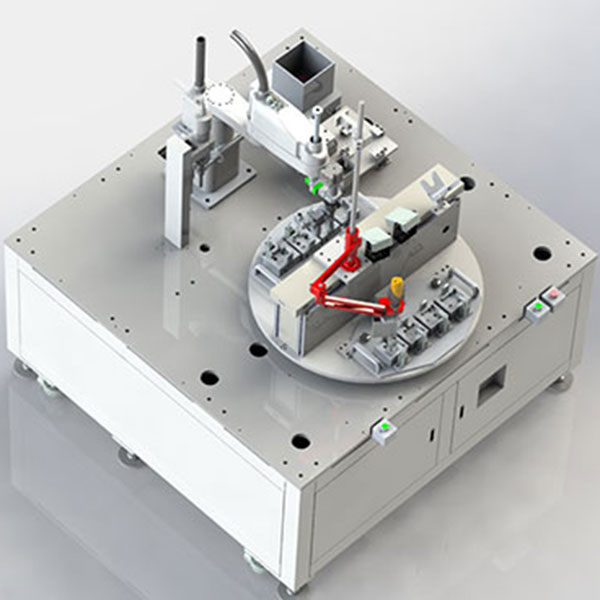

In the rapidly evolving world of manufacturing and testing, the demand for greater precision, speed, and reliability continues to grow. Achieving this balance requires more than just advanced machinery—it calls for the seamless integration of multiple engineering disciplines. Precision mechatronics is where mechanics, optics, and control systems converge to create solutions capable of operating at microscopic tolerances while delivering consistent results. At Jinway Technology Co., Ltd., we specialize in designing and building mechatronic systems that bridge these disciplines, enabling our clients to achieve breakthrough levels of accuracy in production and testing.

Defining Precision Mechatronics

Mechatronics is an interdisciplinary field that combines mechanical engineering, electronics, control systems, and computer science to design and manufacture advanced machines. When applied to precision applications, mechatronics goes a step further by integrating optics into the system design. This combination is essential in industries where measurements are taken at microscopic or nanoscopic scales, such as automotive lighting, optical testing, semiconductor manufacturing, and medical device production. By bringing these elements together, we create systems where mechanical stability, optical accuracy, and intelligent control work in harmony.

The Mechanical Foundation

At the core of any precision mechatronic system is its mechanical design. This involves creating rigid, vibration-resistant structures that can position components with micrometer accuracy. Mechanical elements such as linear motion stages, high-precision bearings, and damping systems form the foundation for reliable performance.

At Jinway, we employ advanced materials and manufacturing techniques to produce mechanical assemblies that can maintain stability under varying loads, temperatures, and operational conditions. The goal is to ensure that any movement—whether rotational or linear—occurs exactly as intended, without deviations that could compromise accuracy.

The Role of Optics in Precision Systems

Optics play a central role in applications where light is used for measurement, inspection, or alignment. In photometric and vision-based testing systems, optical components capture and analyze light to detect defects, measure dimensions, or assess performance.

High-quality lenses, filters, and light sources are selected and aligned with extreme care to ensure that measurements are not distorted by optical aberrations. In some cases, custom optical assemblies are designed to handle specific wavelengths, angles, or illumination patterns required for the application. Precision optics ensure that every photon contributes to a more accurate result.

Intelligent Control Systems

Control systems act as the "brain" of a precision mechatronic setup. They coordinate the movements of mechanical components, the operation of optical sensors, and the processing of data in real time. Advanced control algorithms use feedback from encoders, cameras, and other sensors to adjust positioning and performance instantly.

We integrate programmable logic controllers (PLCs), motion controllers, and embedded computing systems to achieve high-speed, closed-loop control. This allows our machines to react dynamically to changes, correct errors on the fly, and maintain the required level of precision over long operating cycles.

Integration for Accuracy and Stability

The true power of precision mechatronics lies in how mechanics, optics, and control systems are integrated. Even the most advanced components cannot achieve peak performance if they are not properly synchronized. This is where our expertise in system integration ensures that all subsystems communicate flawlessly.

Mechanical stability ensures that the optical system sees the exact target without distortion. Optical accuracy provides the control system with precise data. The control system, in turn, makes minute adjustments to keep the mechanical system operating at its optimal position. This constant feedback loop is the essence of precision mechatronics.

Applications Across Industries

Precision mechatronics has applications in a wide range of industries. In automotive manufacturing, it is used in headlamp photometric testing, where optics and mechanics measure light distribution against strict standards. In the semiconductor industry, it enables wafer inspection with nanometer-scale accuracy. In medical device production, it ensures surgical instruments are manufactured to exact specifications.

At Jinway, our systems are deployed in environments where product quality is critical and tolerances are non-negotiable. By leveraging precision mechatronics, we help clients improve their manufacturing efficiency and maintain compliance with stringent quality standards.

The Future of Precision Mechatronics

As industries demand ever-tighter tolerances and faster production speeds, precision mechatronics will continue to evolve. Emerging technologies such as AI-driven control systems, adaptive optics, and real-time data analytics will enhance system capabilities even further. Digital twin simulations will allow engineers to model mechatronic systems virtually before building them, ensuring optimal performance from the start.

Jinway Technology Co., Ltd. is at the forefront of these advancements, continuously integrating new technologies into our designs to push the limits of what precision machines can achieve.

Conclusion

Precision mechatronics represents the perfect balance of mechanical engineering, optical science, and intelligent control. It is the foundation of high-performance testing and manufacturing systems across multiple industries. By mastering the art of integration, we at Jinway Technology Co., Ltd. deliver solutions that meet the most demanding standards for accuracy, speed, and reliability—helping our clients stay ahead in an increasingly competitive industrial landscape.