Predictive Maintenance with Optical Systems: Keeping Equipment Reliable

In modern manufacturing, reliability is the foundation of productivity. Unexpected equipment failures can halt production lines, delay deliveries, and increase costs. To combat these risks, predictive maintenance has emerged as a powerful strategy, shifting the focus from reactive repairs to proactive interventions. Optical systems now play a crucial role in predictive maintenance, offering precise monitoring capabilities that help manufacturers identify issues before they escalate. By combining optics with data analytics, companies can achieve unprecedented levels of reliability and efficiency. Traditionally, maintenance followed two approaches: reactive and preventive. Reactive maintenance responds to failures after they occur, often resulting in costly downtime. Preventive maintenance schedules routine servicing at set intervals, regardless of actual equipment condition, which can lead to unnecessary repairs. Predictive maintenance, however, leverages real-time monitoring to forecast failures based on actual equipment performance. This method ensures that interventions happen only when needed, reducing both downtime and maintenance costs.

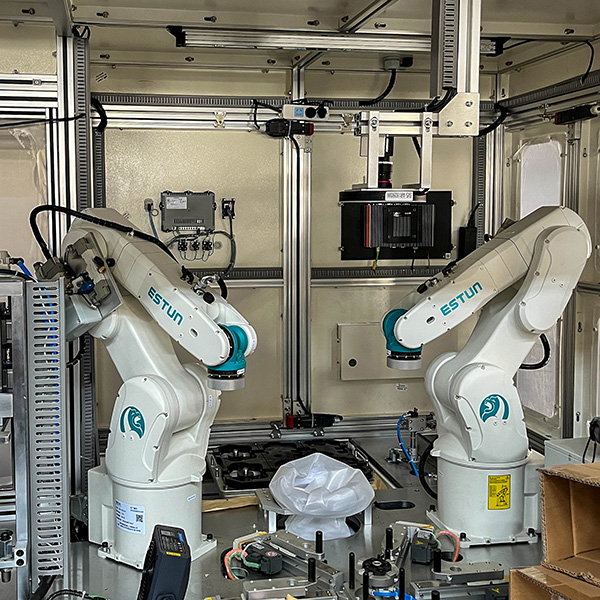

Optical systems provide non-invasive, high-precision monitoring tools that are ideal for predictive maintenance. Cameras, lasers, and photometric sensors can detect subtle changes in equipment condition, such as wear, vibration, misalignment, or surface degradation. Unlike manual inspections, optical systems capture continuous data, offering a complete picture of machine health over time. This constant vigilance ensures that no early warning signs are missed. One of the greatest advantages of optical systems is their ability to detect microscopic changes long before they cause failures. For example, optical sensors can identify early cracks in mechanical parts, shifts in alignment within optical test equipment, or gradual reductions in lighting intensity in photometric systems. By catching these signs early, manufacturers can schedule repairs or part replacements at the most convenient times, avoiding sudden breakdowns.

The real power of optical systems in predictive maintenance comes when they are paired with data analytics and artificial intelligence. Machine learning algorithms analyze the vast amount of optical data collected, identifying patterns and predicting potential failures with high accuracy. These insights allow manufacturers to not only prevent failures but also optimize equipment usage, extending the lifespan of machines and improving return on investment. Implementing predictive maintenance with optical systems provides multiple benefits. Downtime is minimized, as maintenance occurs only when necessary. Resources are used more efficiently, avoiding unnecessary repairs or part replacements. Reliability increases, ensuring that production schedules remain on track. Additionally, predictive maintenance improves safety by reducing the likelihood of catastrophic equipment failures that could endanger workers or damage products.

Optical-based predictive maintenance is valuable across a wide range of industries. In automotive manufacturing, it ensures that testing equipment and assembly lines remain precise and reliable. In aerospace, it helps monitor critical components where even the smallest defect can have serious consequences. In energy and utilities, optical monitoring systems track wear in turbines, solar arrays, or high-voltage equipment. No matter the industry, the principle remains the same: proactive detection safeguards operations. As factories continue to adopt Industry 4.0 technologies, predictive maintenance with optical systems is becoming an integral part of smart manufacturing. By combining precision optics with intelligent analytics, manufacturers are building production environments that are more reliable, cost-effective, and sustainable. Investing in these systems today ensures long-term resilience, enabling companies to stay competitive in demanding global markets.

Predictive maintenance with optical systems represents a major step forward in equipment reliability. By identifying small issues before they escalate, integrating with AI-driven analytics, and reducing downtime, these systems transform maintenance from a burden into a strategic advantage. For manufacturers committed to efficiency and quality, optical-based predictive maintenance is not just a technology upgrade—it is a cornerstone of modern production.