Reducing Lead Time Without Compromising Quality — The Jinway Approach

In the highly competitive automotive lighting industry, speed and quality are often seen as opposing forces. OEM manufacturers demand shorter development cycles and faster delivery to keep pace with rapidly changing markets, yet they are unwilling to accept any compromise on performance, safety, or reliability. Jinway Technology Co., Ltd. has successfully balanced these two priorities by developing a production philosophy that reduces lead time while maintaining uncompromising quality standards. One of the key factors behind Jinway’s efficiency is its early involvement in OEM lighting projects. Rather than entering the process only at the production stage, Jinway actively participates from the design and development phase. By providing technical input on tooling structure, material selection, coating processes, and assembly feasibility, potential manufacturing challenges are identified and resolved early. This proactive collaboration minimizes redesigns, avoids trial-and-error adjustments, and significantly shortens the overall project timeline.

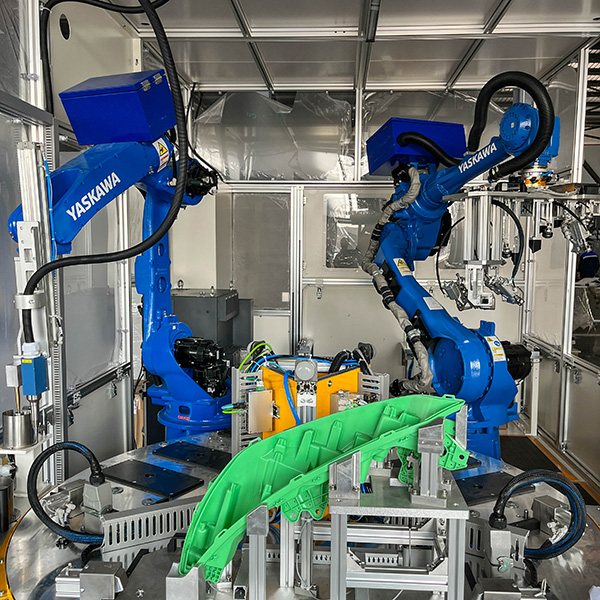

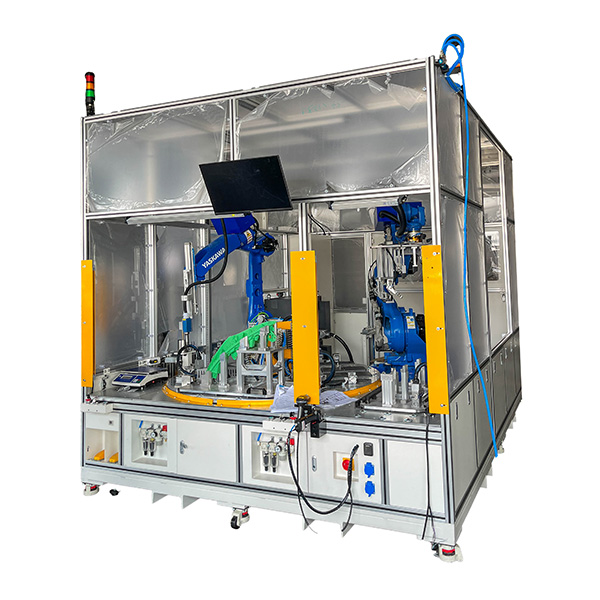

Integrated production capability is another cornerstone of Jinway’s approach. Through close collaboration with strategic partners—Wenton for UV coating lines and ovens, Cexcel for assembly lines, and DJ Mould for tooling—Jinway delivers complete, end-to-end solutions under a coordinated framework. This integration eliminates delays caused by fragmented suppliers, reduces communication gaps, and ensures that each production stage is aligned from the beginning. As a result, equipment installation, commissioning, and ramp-up are completed faster and more smoothly. Automation also plays a critical role in reducing lead time. Jinway’s advanced assembly lines and coating systems are designed for high efficiency and repeatability. Automated processes minimize manual intervention, reduce variability, and enable stable, continuous production. Tasks that traditionally required extended labor hours can now be completed in shorter cycles without sacrificing precision. This consistency allows Jinway to accelerate output while maintaining strict control over quality.

Quality assurance is deeply embedded in Jinway’s production workflow rather than treated as a final checkpoint. Real-time monitoring systems, automated inspections, and in-line testing equipment ensure that deviations are detected immediately. Photometric testing, air leakage detection, and visual inspection systems are integrated directly into the production line. By addressing issues at the source, Jinway avoids costly rework and delays that would otherwise extend lead times. Standardization combined with flexible customization further enhances efficiency. Jinway applies standardized process modules and proven system designs wherever possible, allowing for faster setup and reliable performance. At the same time, these modules are flexible enough to accommodate customized requirements for different OEM projects. This balance enables Jinway to respond quickly to customer needs without starting from scratch for every new project.

A strong technical team underpins all of these efforts. Jinway’s engineers and technicians possess deep expertise in automotive lighting production and are capable of rapid problem-solving. When challenges arise, the team responds immediately with data-driven solutions, preventing minor issues from escalating into major delays. Continuous training ensures the team stays aligned with the latest technologies and industry standards. Ultimately, Jinway’s ability to reduce lead time without compromising quality is the result of a well-coordinated system rather than a single tactic. Early-stage collaboration, integrated partnerships, intelligent automation, and built-in quality control work together to deliver reliable results. This approach not only helps OEM customers bring products to market faster but also strengthens long-term partnerships built on trust and performance. In an industry where timing and quality define success, Jinway Technology Co., Ltd. proves that speed and excellence can coexist. By refining processes and embracing smart manufacturing principles, Jinway continues to deliver high-quality automotive lighting solutions—on time, every time.