Reducing Scrap Rate in Lighting Production Through Smart Equipment Design

Scrap reduction is a major priority in automotive lighting manufacturing, where components involve high-value materials, precision optics, and complex assemblies. Every rejected lens, housing, or assembled lamp represents not only material waste but also lost time, labor, and production capacity. Smart equipment design has become one of the most effective strategies for lowering scrap rates while improving overall manufacturing efficiency. A key principle of smart equipment design is preventing errors before they occur. Traditional systems often rely on end-of-line inspection to catch defects, but by then, value has already been added. Modern lighting production equipment integrates mistake-proofing features—often called poka-yoke mechanisms—that ensure parts are positioned correctly, components match the right model, and assembly steps occur in the correct sequence. These safeguards reduce the chance of human or process errors that lead to scrap.

Precision control systems also play a major role. Automotive lighting components demand tight tolerances in optical alignment, sealing, and coating thickness. Smart machines use servo-driven positioning, automated calibration, and real-time monitoring to maintain process stability. When motion paths, pressures, or temperatures drift outside set limits, the system can automatically correct the parameter or stop production before defects accumulate. Integrated sensing technology further enhances scrap reduction. Sensors monitor variables such as adhesive flow rate, UV curing intensity, air pressure, and part presence. If a dispensing nozzle becomes partially blocked or a UV lamp loses output, the system detects the issue instantly. This early detection prevents large batches of defective parts from being produced before the problem is noticed.

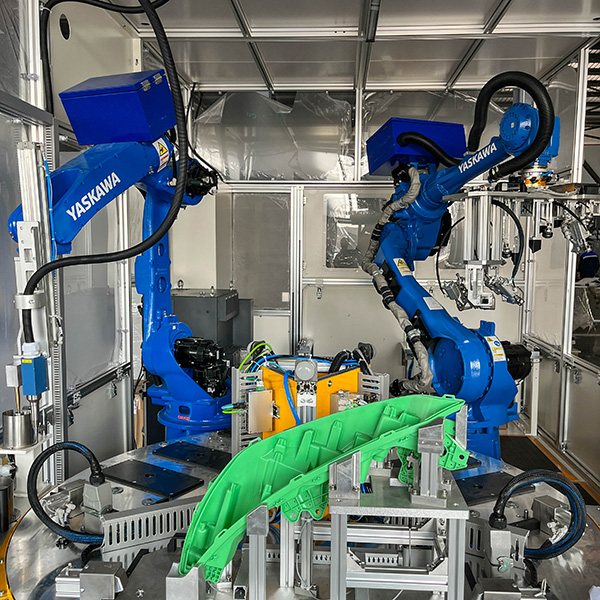

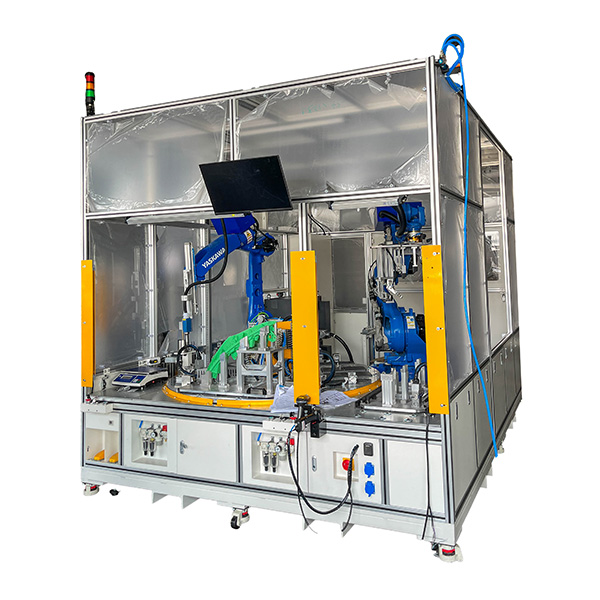

Vision systems have become a cornerstone of smart equipment in lighting production. Cameras combined with image-processing software inspect part orientation, surface quality, and assembly accuracy at multiple stages. Optical defects, misalignments, or contamination can be identified in milliseconds. Because inspection occurs in-line rather than only at the end, defective parts can be removed immediately, protecting downstream processes from compounding the issue. Automation consistency also reduces scrap caused by variability. Robotic dispensing ensures uniform sealant beads, automated coating systems maintain even film thickness, and precision alignment stations position lenses and projectors accurately every time. Removing dependence on manual operations minimizes inconsistencies that can lead to rework or rejection.

Data connectivity is another critical factor. Smart equipment collects production data continuously and feeds it into manufacturing execution systems. Engineers can analyze trends in cycle time, defect frequency, or process variation to identify root causes before they escalate. Predictive maintenance tools use equipment data to anticipate wear or failure, allowing repairs before machine conditions cause quality issues. Smart design also includes user-friendly interfaces and guided workflows. Clear visual instructions, interlocked safety features, and automated recipe selection reduce operator mistakes during changeovers or multi-model production. By simplifying complex tasks and limiting manual adjustments, equipment helps maintain stable output even when product types change frequently.

Material handling systems contribute as well. Gentle, controlled transport prevents scratches or damage to sensitive optical surfaces. Anti-static devices and clean-air enclosures reduce contamination that can lead to cosmetic or functional defects. These protective design features help preserve product quality throughout the production line. Ultimately, reducing scrap through smart equipment design is about building intelligence into every stage of manufacturing. By combining precision mechanics, automation, sensing, data analysis, and user-focused design, lighting manufacturers can minimize waste, lower production costs, and maintain the high quality standards demanded by global automotive customers. In a competitive market, smart equipment transforms scrap reduction from a reactive effort into a proactive, system-wide strategy.