Reducing Warranty Claims with Advanced Optical Testing at the Factory Level

In the competitive landscape of modern manufacturing—especially in the automotive and electronics industries—product reliability and customer satisfaction are critical to brand reputation and long-term success. Warranty claims, which often result from undetected defects or performance issues, can have significant financial and reputational consequences. One of the most effective strategies to reduce these claims is the implementation of advanced optical testing at the factory level. At Jinway Technology Co., Ltd., we specialize in providing high-precision optical testing systems that help manufacturers identify flaws early, ensuring only top-quality products leave the production line.

The Cost of Warranty Claims

Warranty claims are more than just a sign of product failure—they also reflect a breakdown in the manufacturing or quality control process. Each claim typically involves costs related to repair, replacement, logistics, labor, and in some cases, legal liability. More importantly, a high volume of claims can damage brand trust, reduce customer loyalty, and trigger safety recalls or regulatory scrutiny.

Most warranty issues in sectors like automotive lighting, LED modules, or consumer electronics are related to visual performance problems: uneven lighting, misalignment, color variation, flickering, or early failure. These issues are often preventable with robust inspection systems that identify and flag anomalies during production.

The Role of Optical Testing in Quality Assurance

Optical testing involves measuring light-related properties such as intensity, uniformity, color accuracy, and beam distribution. In products where light is a functional or aesthetic element—like automotive headlamps, signal lights, or display panels—these characteristics must meet exact specifications.

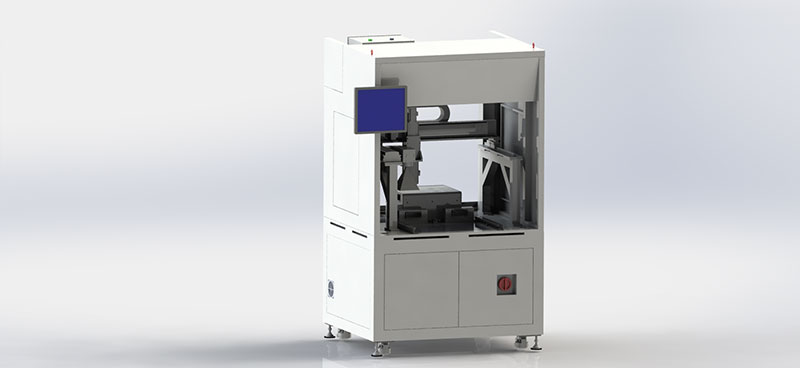

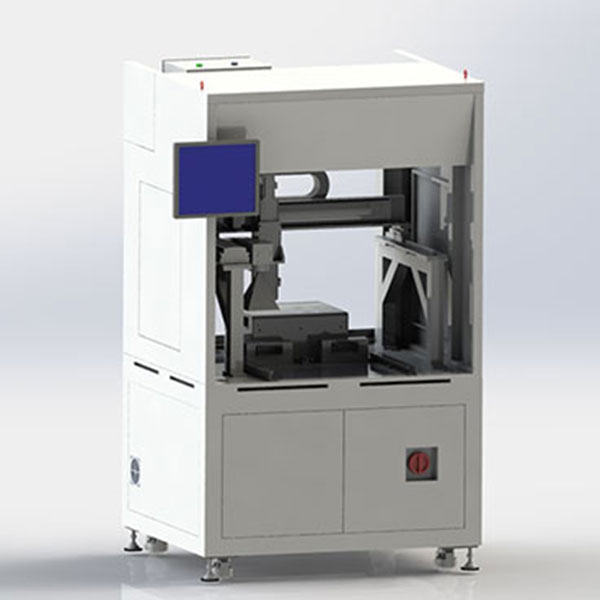

Jinway’s advanced optical test systems are designed to verify that each unit performs to required standards before it moves on to the next production stage or is shipped. By integrating real-time photometric, colorimetric, and visual inspection technologies into the production line, we help manufacturers detect defects that could otherwise result in failures in the field.

Factory-Level Testing: The First Line of Defense

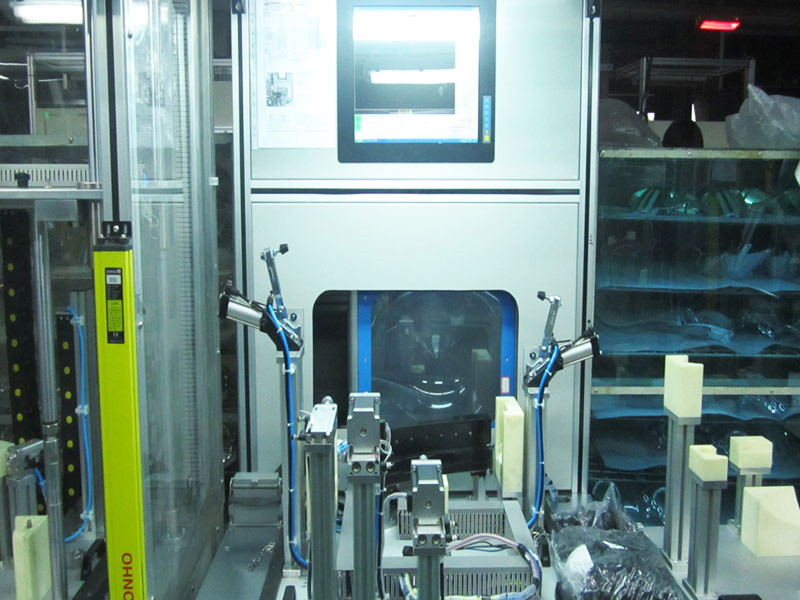

Testing at the end of the production line—commonly known as End-of-Line (EOL) Testing—is crucial, but it’s often too late in the process to prevent costly rework. That’s why we focus on integrated testing solutions that operate earlier in the line, during sub-assembly or component production. This early detection strategy allows manufacturers to address defects when they are easier and less expensive to fix.

For example, our photometric test machines can be embedded into the lighting module assembly process, checking each light for lumen output, beam pattern accuracy, and color uniformity before final assembly. If a module fails any test, it is flagged for review or automatic rejection—preventing the need for disassembly or return after shipping.

Key Features That Reduce Defect Escape Rates

Our systems at Jinway Technology include several features specifically designed to reduce the rate of undetected defects, which are the root cause of many warranty claims:

High-Resolution Vision Systems: Detect micro-level flaws such as cracks, surface scratches, and assembly misalignment.

Precision Photometric Sensors: Measure luminous intensity and beam patterns with high accuracy to ensure compliance with regulatory and brand standards.

Colorimeters and Spectrometers: Verify that LEDs and light sources emit the correct color temperature and chromaticity.

Machine Learning Integration: Recognizes subtle variations in product appearance and performance, learning over time to improve detection accuracy.

Automated Defect Classification: Identifies defect type and severity, enabling targeted responses such as rework, re-calibration, or part replacement.

These features enable near-zero-defect manufacturing, greatly minimizing the chances of faulty units reaching the customer.

Case Application: Automotive Headlamp Manufacturing

Automotive lighting is one of the most demanding areas for optical quality control. Even minor deviations in beam angle or brightness can lead to safety issues and customer complaints. With our integrated test systems, automotive OEMs can conduct 100% inspection of every lighting unit, ensuring that all beam patterns conform to regional regulations such as ECE or SAE.

By identifying issues like LED misalignment, lens defects, or housing warpage early, manufacturers avoid field failures and reduce the volume of warranty-related returns. Over time, this leads to lower warranty costs, stronger OEM relationships, and enhanced brand confidence.

Real-Time Data Logging and Traceability

One of the key advantages of Jinway’s solutions is the ability to log test data for every unit produced, creating a digital footprint that supports traceability and post-sale analysis. If a defect is later reported in the field, manufacturers can trace it back to specific batches or shifts, identify root causes, and implement corrective actions faster.

This data-driven approach also allows manufacturers to track defect trends over time, fine-tune production parameters, and proactively improve quality. As a result, manufacturers not only reduce claims but also build a continuous improvement loop within their quality control framework.

Building Customer Trust Through Quality Assurance

For manufacturers, every product that leaves the factory is a promise of performance. Advanced optical testing ensures that this promise is fulfilled, time after time. When customers consistently receive products that meet or exceed expectations, warranty claims go down and brand loyalty goes up.

Moreover, as products become more advanced and consumer expectations rise, the margin for error shrinks. Proactive quality measures like factory-level optical testing become essential—not just for compliance, but for competitiveness.

Conclusion

Reducing warranty claims begins on the production floor, not at the service desk. By investing in advanced optical testing systems at the factory level, manufacturers can dramatically improve product reliability, minimize costly returns, and protect their reputation. At Jinway Technology Co., Ltd., our mission is to provide the tools and technology that empower our clients to deliver consistently high-quality products—ensuring that what’s shipped is built to last.