Rendering Mold Dispensing Machines: Enhancing Accuracy in Lighting Production

In today’s automotive lighting industry, precision is everything. As headlights and taillights evolve into complex optical assemblies with tighter tolerances, perfect sealing, bonding, and component placement have become essential for product reliability and safety. Rendering Mold Dispensing Machines play a vital role in meeting these high standards, offering manufacturers a way to achieve consistent accuracy during critical production steps. These machines are designed to dispense adhesives, sealants, and resins with exceptional control. Automotive lighting components often require intricate sealing paths, UV-resistant bonding, and micro-level precision to ensure proper fit and long-term performance. Manual application not only slows down production but also increases the risk of inconsistency. Rendering Mold Dispensing Machines eliminate these challenges by delivering uniform material flow and precise dosing for every product, regardless of complexity.

One of the key advantages of using dispensing machines in lighting production is the improvement in product quality. Modern headlights include multiple reflectors, lenses, and electronic modules, all of which must be sealed tightly to prevent moisture ingress, fogging, or optical distortion. High-precision dispensing ensures that sealing materials are accurately applied along edges and joints, allowing lamps to remain durable under harsh weather, temperature changes, and long-term vibrations. Efficiency is another major benefit. Automated dispensing systems significantly reduce production cycles by working faster than manual operators. They can maintain a stable flow, adjust automatically to different molds, and repeat the same task thousands of times without deviation. For manufacturers in the OEM automotive lighting industry—where large volumes and tight deadlines are the norm—this level of consistency directly contributes to reduced lead times and increased productivity.

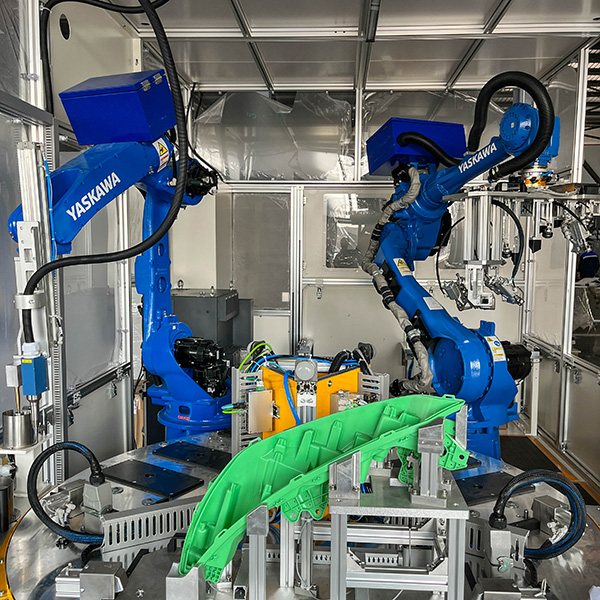

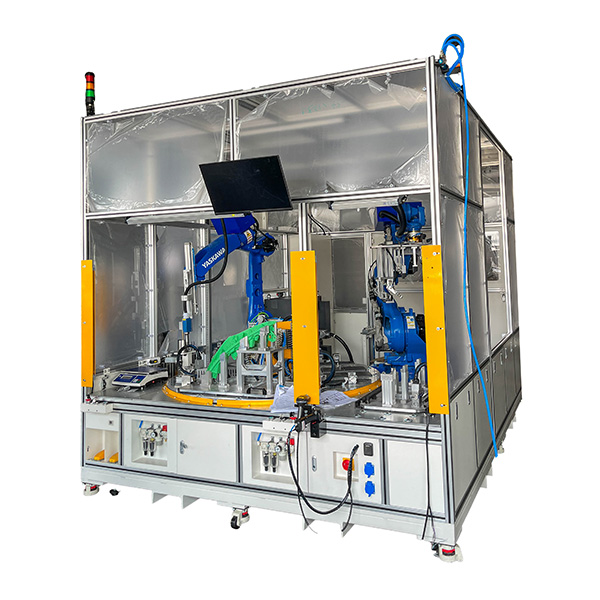

In addition to accuracy and speed, modern dispensing machines support better integration within automated assembly lines. For companies like Jinway, which offer complete turnkey solutions including tooling, assembly lines, and coating systems, rendering mold dispensing machines fit naturally into the production ecosystem. Their compatibility with robotic arms, conveyors, and smart sensors allows them to perform seamlessly as part of a fully automated workflow. Technological advancements have also improved the capability of these machines. Today’s dispensing systems can handle multiple material types, detect irregularities in real time, and adapt their flow rate through intelligent algorithms. This reduces waste, enhances safety, and ensures optimal adhesion strength in every lighting component produced. Such improvements align perfectly with global automotive trends toward smarter and more sustainable manufacturing processes.

Ultimately, Rendering Mold Dispensing Machines contribute to the overall goal of zero-defect production. By ensuring accurate material application and preventing issues like leakage, incomplete sealing, or uneven adhesive distribution, they help eliminate the root causes of product failure. This enhances customer satisfaction and ensures compliance with the stringent standards of automotive OEMs worldwide. As the automotive lighting industry moves toward more advanced designs and higher performance expectations, the need for precise, reliable, and automated dispensing solutions will only continue to grow. With strong technical expertise and integrated production capabilities, companies like Jinway are well-positioned to support these needs and deliver superior lighting components to the global market.