Space, EVs, and Beyond: How Optical Test Systems Are Expanding Across Industries

Optical test systems have long played a central role in industries that demand precision in light output, positioning, and appearance—most notably, the automotive sector. However, with the rise of new technologies and stricter quality demands across sectors, these systems are now finding applications in a growing list of high-tech industries. From electric vehicles (EVs) to aerospace, medical devices, and smart consumer products, the need for advanced optical testing has never been greater. At Jinway Technology Co., Ltd., we are at the forefront of this expansion, adapting our photometric and vision-based test solutions for use in sectors that go far beyond their original automotive roots.

The Rise of Optical Testing in the EV Industry

The electrification of mobility has opened up new challenges in lighting and display systems that go well beyond what was seen in traditional vehicles. EVs feature extensive use of LED lighting, ambient illumination, adaptive headlamps, and high-resolution displays. These components must not only look good but also function with exceptional reliability, often under stringent energy efficiency and thermal management constraints.

Our optical test systems help EV manufacturers ensure that lighting modules meet strict performance standards across all operating conditions. Whether validating the color temperature of a dashboard display or testing the photometric performance of adaptive beam projectors, our solutions offer the high-resolution analysis and real-time data output required in modern EV production lines.

Meeting the Demands of Aerospace and Space Applications

The aerospace industry is another sector where optical testing is seeing rapid adoption. Illumination and display systems in aircraft cabins, cockpits, and navigation units must operate flawlessly under extreme environmental conditions—high altitudes, temperature shifts, vibration, and radiation exposure.

In space exploration, even more precise optical validation is required. Components such as solar sensors, camera optics, signal indicators, and inspection lights must undergo rigorous testing to verify both performance and durability. Our systems are tailored to meet these demands through high-sensitivity photometric measurement, color stability analysis, and structural alignment verification using machine vision.

As aerospace manufacturers increasingly rely on advanced LED and fiber-optic technologies, Jinway’s solutions are proving critical in achieving the accuracy, repeatability, and traceability needed for mission-critical operations.

Optical Testing in the Medical Technology Sector

Precision lighting is not only important in vehicles and aircraft but also in medical devices. Equipment such as surgical lights, endoscopic tools, diagnostic instruments, and wearable health monitors often incorporate illumination or display elements that require accurate calibration.

Optical test systems are used in the medical sector to ensure that devices emit light at the correct wavelength, intensity, and color for safe and effective use. For example, a slight deviation in color temperature in surgical lighting could affect a surgeon’s ability to distinguish tissue tones. In diagnostics, accurate light-based measurements are crucial for ensuring that sensor-driven results are reliable.

Our customizable testing platforms provide detailed spectral data, intensity distribution, and real-time quality validation—helping medical device manufacturers maintain compliance with both national and international safety standards.

Smart Consumer Electronics and IoT Devices

In consumer electronics, visual quality is a key factor in brand differentiation and user satisfaction. Devices such as smartphones, smartwatches, home assistants, and wearable displays rely heavily on LEDs, OLEDs, and miniaturized light sources for displays, indicators, and user interfaces.

Consumers expect these devices to deliver perfectly calibrated light output—free from color inconsistencies, flickering, or uneven brightness. Our compact and high-speed test platforms enable manufacturers to perform end-of-line inspection and calibration of light-emitting components, ensuring a consistent experience across all units.

For Internet of Things (IoT) devices, where form factors are small and lighting is often used for feedback and status indication, our systems help verify that visual signals remain consistent and accurate in every usage environment.

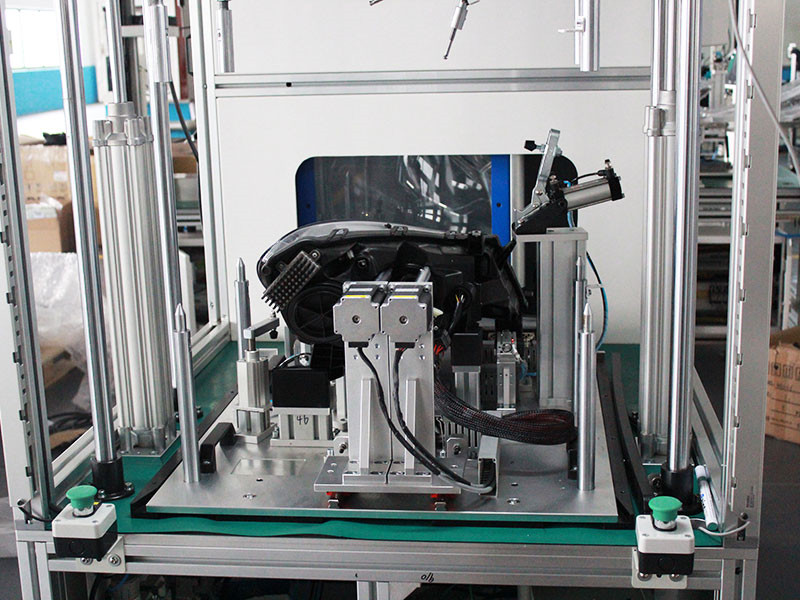

Enabling Modular and Scalable Testing Architectures

One key advantage of Jinway’s optical test systems is their modularity and scalability. As our clients expand into new industries, we adapt our systems to meet changing form factors, measurement requirements, and integration needs. Whether it's a benchtop unit for lab validation or an in-line system embedded in a high-speed production line, we ensure that performance, accuracy, and reliability are never compromised.

In industries such as space and medical, where traceability is critical, our systems are equipped with advanced data logging and connectivity features. Measurement results are recorded and can be linked to individual product IDs, allowing full traceability and compliance with quality audits.

Supporting Industry 4.0 and Smart Manufacturing

As more industries adopt Industry 4.0 principles—such as real-time monitoring, predictive analytics, and digital twins—the role of smart testing becomes increasingly important. Optical test systems are evolving to support these goals, providing rich datasets that can feed into AI models, MES platforms, and automated quality control systems.

Our solutions support data export in standardized formats and offer integration options for cloud-based analytics, edge computing, and remote diagnostics. This flexibility allows customers to use testing not just as a quality gate, but as a strategic tool for optimizing production, reducing downtime, and increasing product consistency.

Conclusion

What started as a specialized tool for headlamp validation has become a foundational technology across a wide array of industries. Optical test systems are now essential in sectors as diverse as electric vehicles, aerospace, medical technology, and consumer electronics—wherever precision light performance is required. At Jinway Technology Co., Ltd., we are committed to leading this evolution, designing adaptable, high-performance test systems that meet the diverse needs of tomorrow’s manufacturers. As technology advances, the scope and importance of optical testing will only grow—lighting the way forward across industries.