Sustainable Automation: How Energy-Efficient Test Systems Lower Costs and Carbon Footprints

As industries move toward greener practices, sustainability is no longer an option but a necessity. Energy efficiency and carbon reduction are becoming central goals for manufacturers worldwide, and automation plays a vital role in achieving them. At Jinway Technology Co., Ltd., we focus on building sustainable automation systems that not only enhance production quality but also minimize energy consumption. By designing energy-efficient test systems, we help manufacturers reduce operational costs while supporting global efforts to lower carbon footprints.

The Link Between Automation and Sustainability

Automation has traditionally been associated with productivity and precision. However, the latest generation of automation technologies extends beyond efficiency to include environmental responsibility. Modern test systems are now designed to consume less energy, use smarter controls, and integrate renewable-friendly power strategies. This shift enables factories to meet both economic and environmental goals simultaneously, creating a more resilient and future-ready production environment.

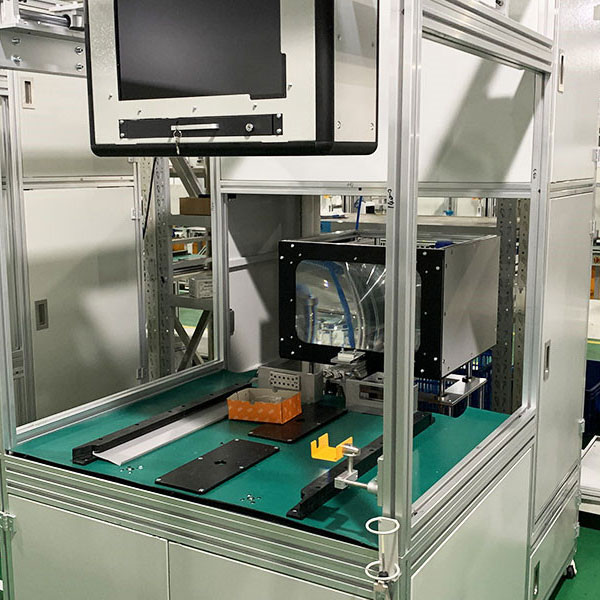

Energy Efficiency in Test Systems

Energy-efficient test systems are engineered to maximize performance while minimizing power consumption. For example, advanced photometric testing equipment uses optimized LED light sources, precision optics, and low-power sensors that achieve accurate results without unnecessary energy waste. Intelligent control algorithms further enhance efficiency by powering down components when not in use or dynamically adjusting energy loads based on testing requirements. These design choices significantly reduce the overall electricity demand of production lines.

Cost Savings Through Efficiency

Reducing energy consumption directly translates into lower operational costs. In large-scale manufacturing facilities where hundreds of tests may be performed every hour, even small energy savings per cycle can accumulate into significant annual reductions in electricity bills. For companies operating in regions with high energy costs or carbon taxes, energy-efficient systems offer a clear financial advantage. At Jinway, our clients often find that the return on investment in sustainable automation comes not only from improved quality but also from long-term cost savings.

Reducing Carbon Footprints

Beyond financial benefits, energy-efficient test systems contribute to the reduction of greenhouse gas emissions. Since most industrial electricity still comes from fossil fuel sources, lowering energy usage directly decreases a company’s carbon footprint. By implementing sustainable automation, manufacturers can demonstrate commitment to corporate social responsibility and meet increasingly stringent environmental regulations. In industries like automotive, where suppliers are expected to align with global sustainability goals, this can be a powerful differentiator.

Intelligent Power Management

A critical enabler of sustainable automation is intelligent power management. Modern test systems are equipped with smart controllers that can balance energy loads, reduce idle consumption, and recover energy where possible. For example, regenerative braking in motor-driven systems allows excess energy to be redirected rather than wasted. Similarly, predictive control software ensures that systems only consume the energy they need, precisely when they need it. These intelligent mechanisms maximize efficiency without compromising accuracy.

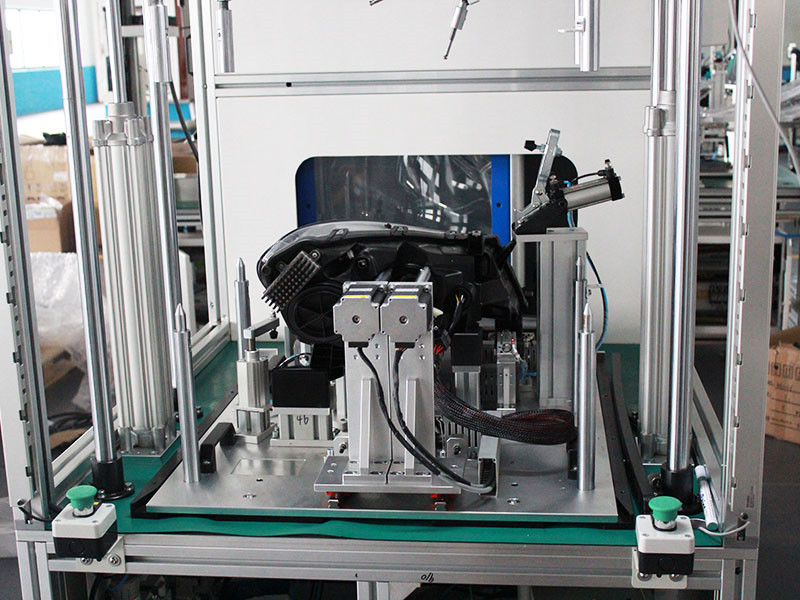

Case Study: Automotive Lighting Tests

Automotive lighting is one area where sustainable automation delivers measurable results. Traditional optical test setups often consumed excessive energy due to high-intensity lamps and inefficient cooling systems. By switching to LED-based light sources, advanced optics, and optimized sensor arrays, energy consumption is drastically reduced while testing accuracy improves. Jinway’s energy-efficient systems enable automotive suppliers to meet strict photometric standards while lowering both costs and environmental impact.

Long-Term Reliability and Maintenance

Energy-efficient systems are not only greener—they are also more reliable. Reduced energy demands place less stress on components, leading to longer equipment lifespans and lower maintenance requirements. This directly supports sustainability by decreasing the need for spare parts and minimizing resource use over the lifecycle of the equipment. The combination of low energy consumption and high reliability makes these systems an ideal investment for future-focused manufacturers.

Toward a Greener Manufacturing Future

The push for sustainability in manufacturing will only accelerate as global industries adopt carbon-neutral goals. Emerging technologies such as AI-driven process optimization and integration with renewable power grids will further enhance the sustainability of automation systems. At Jinway Technology Co., Ltd., we continue to innovate in this direction, ensuring that our clients benefit from systems that combine top performance with minimal environmental impact.

Conclusion

Sustainable automation is transforming the way manufacturers think about production. Energy-efficient test systems are not only tools for ensuring quality and precision—they are also powerful drivers of cost savings and carbon reduction. By designing systems that consume less power, operate more intelligently, and last longer, Jinway Technology Co., Ltd. helps industries align with global sustainability goals. The future of manufacturing belongs to companies that can balance productivity with environmental responsibility, and sustainable automation is the key to achieving that balance.