Sustainable Manufacturing Practices in Automotive Lighting Production

As the global automotive industry accelerates toward a greener future, sustainability has become more than just a trend—it is a fundamental responsibility. From electric vehicles to energy-efficient components, manufacturers are being called upon to reduce environmental impact while maintaining performance and innovation. In the automotive lighting sector, sustainable manufacturing practices play a vital role in balancing productivity with environmental stewardship. Jinway Technology Co., Ltd., as a specialist in OEM automotive lighting solutions, is actively contributing to this transformation through advanced technologies, efficient processes, and intelligent resource management. One of the most significant environmental challenges in traditional manufacturing is excessive energy consumption. Automotive lighting production involves multiple stages, including tooling, assembly, surface treatment, coating, and testing. Each stage requires equipment, electricity, and raw materials. Jinway addresses this challenge by integrating energy-efficient systems into its production lines, especially in its UV coating lines and ovens. UV curing technology, in particular, is far more energy-efficient than traditional heat-based curing methods. It uses ultraviolet light to instantly harden coatings, significantly reducing processing time and power usage while delivering a superior surface finish.

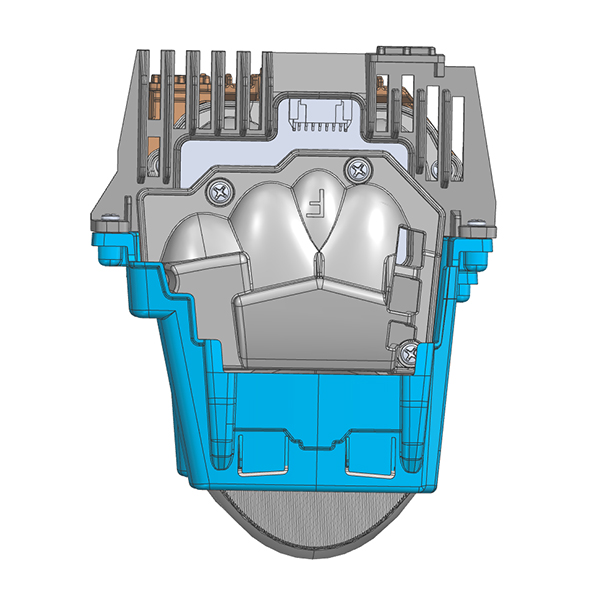

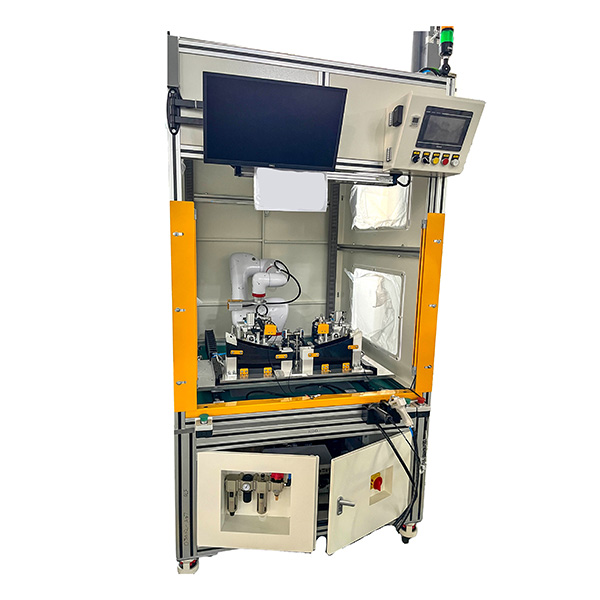

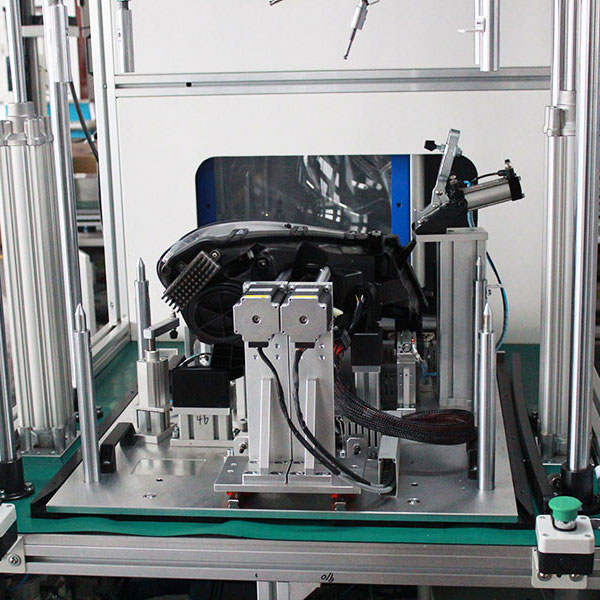

Material optimization is another key element in sustainable manufacturing. Automotive lighting components typically use polycarbonate plastics, metals, and specialized coatings. Minimizing material waste during production is essential for reducing environmental footprints. Jinway’s advanced tooling solutions, developed in cooperation with DJ Mould, enable high-precision manufacturing with minimal material loss. Well-designed molds ensure accurate dimensions and consistent quality, meaning fewer defects, fewer rejected parts, and less wasted material. This precision not only benefits the environment but also improves cost efficiency for OEM customers. Automation and intelligent control systems also contribute significantly to sustainable practices. Jinway’s auto lamp assembly lines, built with Cexcel, are designed to maximize productivity while reducing unnecessary material and energy usage. Automated processes reduce human error and increase consistency, which lowers the rate of defective products. With fewer defects, there is less rework and scrap, and therefore less waste. At the same time, automated systems optimize cycle times and energy use, ensuring that production processes are both fast and efficient.

Coating technology is another area where sustainability is making a major impact. Traditional solvent-based coatings can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and health risks. Jinway’s UV coating and anti-fog coating systems are designed to minimize or eliminate VOC emissions. These advanced coating solutions are environmentally friendly while still providing excellent durability, scratch resistance, and clarity for automotive lighting components. By choosing cleaner coating technologies, Jinway helps customers meet stricter environmental regulations without sacrificing quality. Water conservation is also becoming an increasingly important focus. In many manufacturing environments, water is used for cooling, cleaning, and surface preparation. Jinway implements optimized cleaning processes and recirculation systems that reduce total water consumption. By using closed-loop systems and environmentally friendly cleaning agents, the company minimizes water waste and limits harmful discharge into the environment. These practices reflect Jinway’s commitment to sustainable resource management at every level of production.

Beyond environmental responsibility, sustainable manufacturing also supports long-term economic sustainability for customers. Durable lighting components that resist UV damage, fogging, and wear last longer and require fewer replacements. Jinway’s UV-coated and anti-fog treated lamp components offer extended service life, reducing the need for frequent repairs or part replacements. This extended lifespan not only reduces material consumption over time but also provides significant cost savings for vehicle manufacturers and end users. Jinway’s commitment to sustainability extends to its role as a technology partner in product development. By participating actively in the design stage of new automotive lighting projects, Jinway offers valuable suggestions for improving efficiency, reducing material use, and enhancing recyclability. This early-stage involvement helps OEM manufacturers incorporate eco-friendly design principles from the very beginning, ensuring that sustainability is built into the product, not added as an afterthought.

As global regulations become stricter and consumer awareness continues to rise, sustainable manufacturing is no longer optional—it is essential for long-term success. Automotive brands are under increasing pressure to demonstrate environmental responsibility throughout their supply chains. Jinway, with its advanced production systems, strategic partnerships, and strong technical team, is well positioned to support this shift. By providing efficient assembly lines, low-emission coating technologies, precision tooling, and integrated quality control systems, Jinway enables its customers to achieve both high performance and high environmental standards. In an industry that is constantly evolving, sustainable manufacturing is not a final destination but an ongoing journey of innovation and improvement. Jinway Technology Co., Ltd. remains committed to advancing this journey by combining smart engineering with responsible practices. Through continuous optimization and future-focused solutions, Jinway is not only shaping the future of automotive lighting—but doing so in a way that protects the world we drive through.