Testing Adaptive Headlamps and Intelligent Light Patterns Evaluation

As vehicles become increasingly intelligent, lighting systems are evolving beyond simple illumination. Modern cars now feature adaptive headlamps and intelligent light patterns—technologies designed to enhance visibility, improve driver comfort, and boost road safety. These systems adjust light direction, intensity, and distribution in real time, responding dynamically to traffic conditions, speed, weather, and terrain. However, ensuring that such systems operate safely and effectively requires advanced photometric testing. Rigorous evaluation guarantees that adaptive lighting systems perform consistently and comply with global safety standards, making them both innovative and reliable.

Automotive lighting has come a long way from traditional halogen bulbs to LED and laser-based illumination. Adaptive headlamps represent the next frontier, using sensors, cameras, and intelligent algorithms to optimize light output automatically. They can dim specific portions of the beam to avoid dazzling oncoming drivers, extend range on open roads, or widen illumination in urban environments. Intelligent light patterns further enhance performance by shaping beams to suit real-world driving scenarios. Testing these complex systems ensures that advanced lighting doesn’t just look futuristic—it functions with precision and safety.

Adaptive headlamps introduce new challenges for test engineers. Unlike conventional lamps that have fixed beam patterns, adaptive systems continuously change their output based on sensor feedback. Testing must therefore go beyond static measurements; it must analyze light behavior dynamically. Photometric testing systems measure luminous intensity, distribution uniformity, color temperature, and response time across a variety of simulated driving conditions. This ensures that headlamps respond accurately to environmental cues and maintain compliance with ECE, SAE, and DOT regulations.

A key focus of adaptive headlamp testing is the evaluation of dynamic light distribution. Advanced test benches equipped with goniophotometers and moving mirrors simulate real-world scenarios where light patterns shift in milliseconds. Engineers capture and analyze these transitions to verify that beam movements are smooth, precise, and safe for all road users. Any lag, misalignment, or uneven transition could lead to glare or insufficient road illumination. Through controlled testing, manufacturers can fine-tune algorithms and mechanical components to achieve optimal light distribution performance.

Adaptive lighting systems rely heavily on environmental sensors—cameras, radar, and LiDAR—to detect vehicles, pedestrians, and road features. Photometric testing must therefore include sensor-response validation. Engineers recreate conditions such as approaching headlights, streetlights, and varying weather to evaluate how quickly and accurately sensors trigger lighting adjustments. The timing between detection and response is critical; even slight delays can affect driver visibility and safety. Testing ensures that the headlamp’s reaction is instantaneous and correctly aligned with its intended purpose.

Intelligent light systems use advanced optics and control software to create customized light shapes. For example, matrix LED systems can selectively turn off individual LEDs to block glare for oncoming vehicles while maintaining illumination elsewhere. Testing these intelligent patterns involves assessing pixel-level control, uniformity, and precision of light cutoff. Engineers use high-resolution imaging systems to analyze the exact shape of projected beams and confirm that they meet defined optical boundaries. This ensures compliance with global photometric standards and guarantees that adaptive beams enhance visibility without causing discomfort to other drivers.

Simulating real-world environments is a critical step in adaptive lighting evaluation. Test chambers equipped with rotating mirrors, projection screens, and environmental controls recreate various road and weather conditions—fog, rain, snow, and tunnel lighting. Photometric systems record how adaptive headlamps adjust to these changing environments. Additionally, on-road testing complements laboratory simulations by validating system performance in unpredictable, real-life situations. This combination ensures that adaptive lighting behaves reliably under every possible driving scenario.

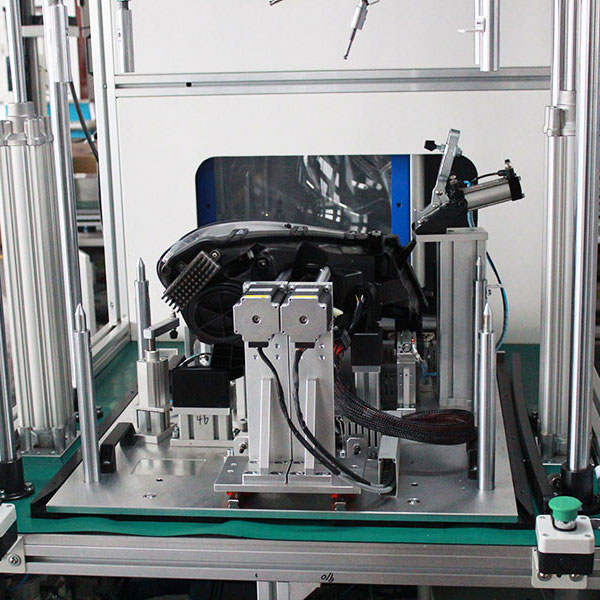

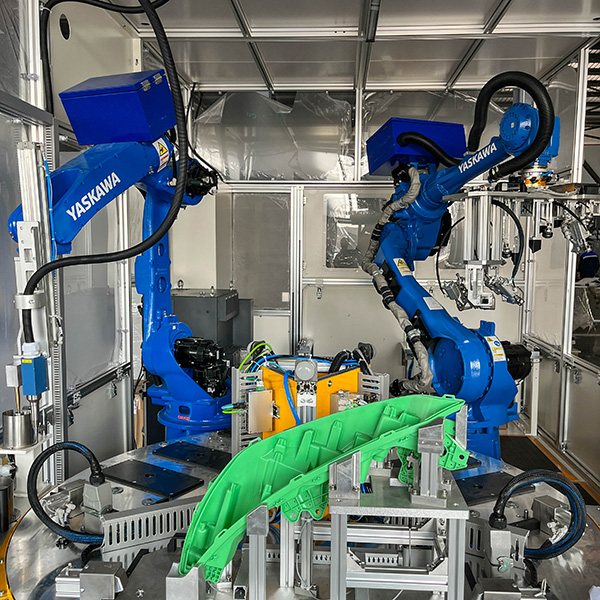

To handle the complexity of adaptive systems, modern test setups incorporate automation and data integration. Automated positioning systems align headlamps precisely, while high-speed cameras and photometers collect real-time performance data. Artificial intelligence analyzes these massive datasets to identify trends, deviations, and optimization opportunities. This automation not only speeds up the testing process but also increases consistency and reduces human error. The result is a faster, more accurate, and repeatable validation process for every headlamp system.

Meeting international lighting regulations is essential for bringing adaptive headlamps to market. Standards such as ECE R112, ECE R123, and FMVSS 108 define acceptable beam shapes, intensity limits, and glare control parameters. Photometric testing ensures that each adaptive lighting configuration remains within legal boundaries while still delivering maximum illumination. Advanced test systems can automatically generate compliance reports, streamlining the certification process and ensuring that all documentation aligns with regulatory requirements.

Artificial intelligence is transforming the way adaptive headlamps are tested and optimized. AI algorithms analyze photometric data to detect micro-level inconsistencies in beam transitions and predict potential failure points. Machine learning models can simulate thousands of road conditions, helping engineers refine system performance before physical testing. Over time, this data-driven approach reduces development cycles and improves both safety and efficiency, paving the way for smarter, self-optimizing lighting systems.

Once deployed, adaptive headlamp systems can benefit from continuous monitoring and predictive maintenance. Cloud-connected photometric test data helps manufacturers track long-term performance trends, identify early signs of degradation, and update control software remotely. This proactive approach ensures that lighting systems maintain peak performance throughout their lifespan, minimizing field failures and warranty claims while upholding safety standards.

The future of adaptive lighting testing lies in full-system simulation and digital twin technology. These innovations allow engineers to create virtual replicas of lighting systems, test them under dynamic conditions, and refine performance before physical prototypes are built. Combined with real-time feedback from AI analytics, digital testing will enable even faster innovation cycles and higher accuracy in adaptive headlamp development. As vehicles continue to move toward full autonomy, intelligent lighting will play an increasingly central role in ensuring visibility and communication between vehicles and their surroundings.

Testing adaptive headlamps and intelligent light patterns is a critical step in advancing modern automotive safety and performance. Through precise photometric evaluation, manufacturers ensure that lighting systems adapt seamlessly to dynamic environments without compromising visibility or comfort. By integrating automation, AI, and cloud-based monitoring, the industry is redefining how optical systems are tested, validated, and maintained. As vehicles become smarter and more connected, advanced photometric testing will remain essential—illuminating not just the road ahead, but the future of safe, intelligent mobility.