The Future of Automotive Lighting Manufacturing in the Era of Electric Vehicles

The rapid shift toward electric vehicles is transforming the entire automotive industry, and lighting manufacturing is no exception. As EVs become more advanced, efficient, and intelligent, the expectations placed on automotive lighting systems are evolving just as quickly. Manufacturers that once focused primarily on illumination and design must now adapt to new technological demands, tighter integration, and higher performance standards. One of the biggest changes brought by electric vehicles is the heightened focus on energy efficiency. EVs rely entirely on battery power, making every watt of consumption important. This has accelerated the adoption of high-efficiency LED and laser lighting systems, which offer strong illumination while minimizing energy usage. Automotive lighting suppliers are now expected to engineer components that not only perform well but also support the overall energy-saving goals of electric vehicles.

Beyond efficiency, the era of EVs is driving the industry toward smarter and more connected lighting solutions. Electric cars often include advanced driver-assistance systems, sensors, and onboard computers that rely on integrated lighting functions. Matrix LED headlights, adaptive beams, and welcome-light animations are becoming standard features, pushing manufacturers to develop lighting components with greater precision and tighter electronic integration. This requires suppliers to invest in new technologies, advanced tooling, and intelligent assembly systems that ensure perfect alignment and superior optical performance. Design innovation is another area experiencing rapid transformation. EVs provide designers with more freedom because electric motors and battery platforms change the structure of the vehicle. As a result, lighting has become an important branding tool, with many EV manufacturers using signature lightbars, dynamic indicators, and dramatic front and rear lighting to distinguish their models. This trend creates opportunities and challenges for lighting suppliers who must deliver highly customized components without sacrificing manufacturability or consistency.

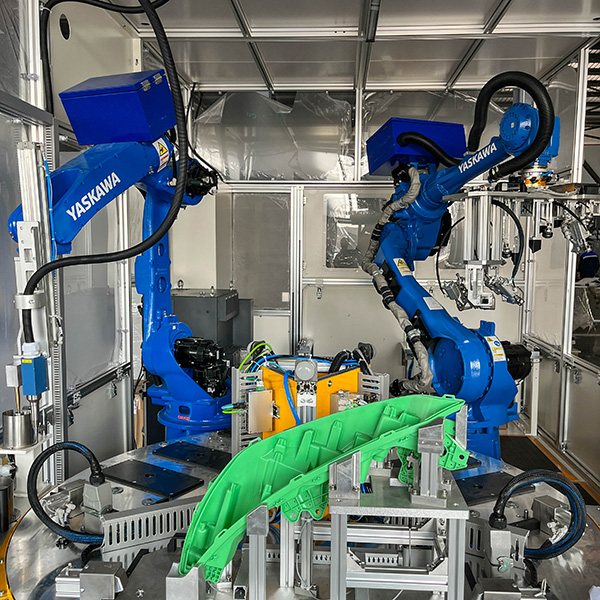

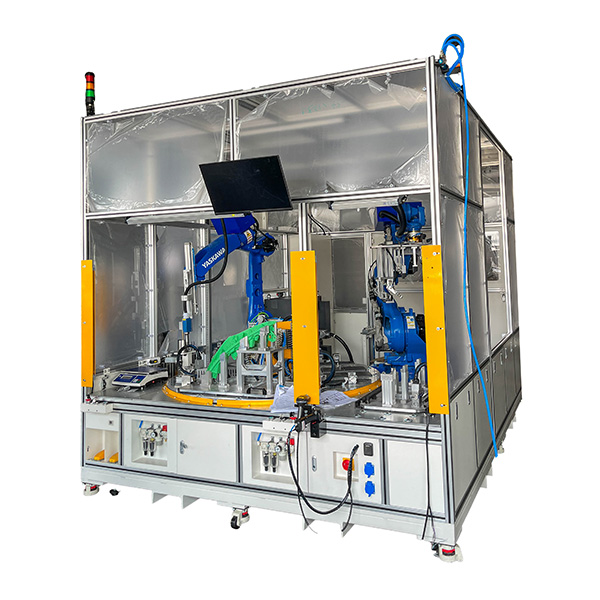

The rise of electric vehicles also increases the importance of high-quality surface treatments and coatings. Lightweight materials, aerodynamic designs, and transparent covers require more advanced coatings—from UV-resistant layers to anti-fog solutions—to protect lamp components from harsh environments. Companies like Jinway, with strong expertise in UV coating lines, anti-fog technology, and precision assembly, are well-positioned to support these emerging needs and ensure long-lasting performance. Automation and digitalization will play a major role in the future of EV lighting manufacturing. Smart factories equipped with robotic assembly lines, automated inspection systems, and data-driven quality control will become standard, enabling zero-defect production and greater repeatability. Photometric testing equipment, air leakage detection systems, and intelligent final inspection tools will continue to be essential for ensuring that lighting components meet increasingly strict global standards.

Finally, sustainability is shaping the future of the industry. EV manufacturers and their suppliers are under growing pressure to adopt environmentally friendly production methods. From greener materials and efficient coating lines to energy-saving processes and recyclable components, lighting makers must invest in sustainable solutions that align with the environmental mission of electric vehicles. The transition to electric mobility is not just a trend—it is a long-term shift that is redefining how automotive lighting is designed, produced, and validated. Manufacturers that embrace innovation, automation, and high-quality engineering will thrive in this new era. As electric vehicles continue to advance, companies like Jinway will play a critical role in delivering the next generation of high-performance, efficient, and visually striking lighting systems that define the future of automotive design.