The Importance of Technical Support in OEM Automotive Lighting Projects

In the fast-evolving automotive lighting industry, OEM manufacturers rely heavily on suppliers who can do more than just deliver components—they need partners who offer strong technical support throughout the entire product development cycle. As carmakers push for higher performance, advanced lighting technologies, and rapid innovation, the role of technical support has become crucial to ensuring efficiency, reliability, and competitive advantage. Technical support is essential from the earliest stages of an OEM lighting project. Before tooling, coating, or assembly even begins, engineers must collaborate closely to refine product concepts, optimize design structures, and confirm feasibility. This early involvement helps prevent costly redesigns later and ensures that every component—from projector lenses to leveling motors—can be manufactured with precision and consistency. Companies like Jinway provide valuable insights during this stage, offering advice on material selection, mold design, optical performance, and structural stability.

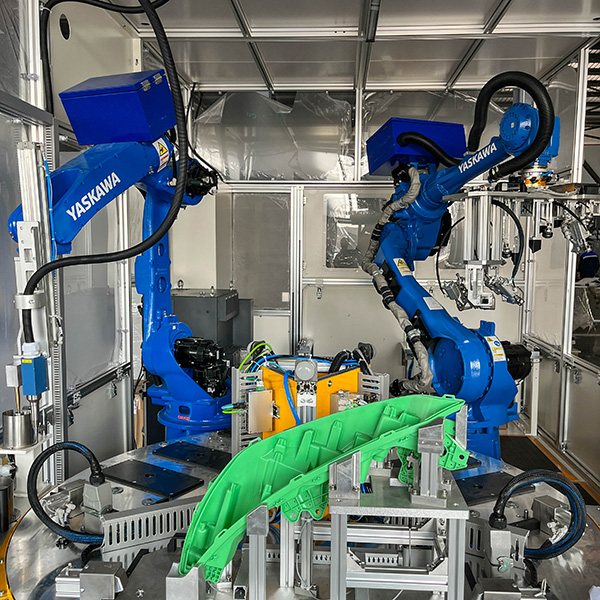

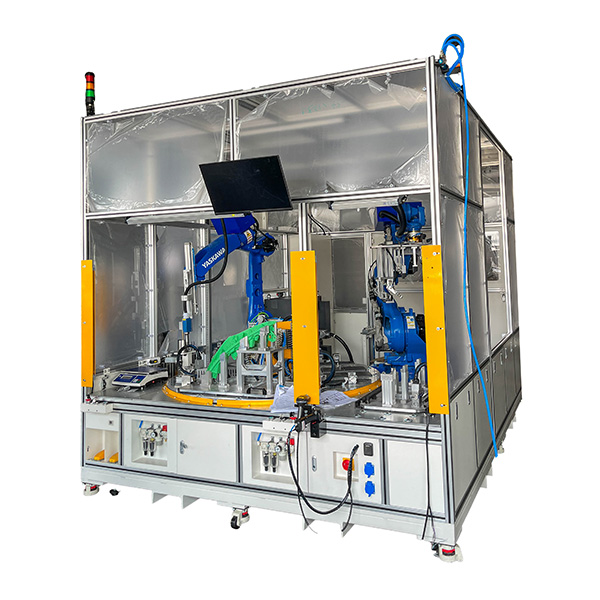

During the development phase, technical support becomes even more critical. Automotive lighting systems today involve complex technologies such as LED modules, advanced coatings, and multi-stage assembly processes. Without the right technical guidance, delays and performance issues can easily arise. By working side-by-side with OEM teams, Jinway’s engineers help refine specifications, adjust process parameters, and solve technical obstacles that could otherwise impact production schedules. This collaborative approach ensures that prototypes evolve smoothly into full-scale production. Once production begins, ongoing technical support is key to maintaining quality and reducing risk. Whether it involves adjusting coating line settings, fine-tuning assembly processes, or optimizing anti-fog and UV coating performance, consistent technical expertise ensures every stage meets global safety and durability standards. Jinway’s strong technical team monitors results, analyzes data from testing equipment, and provides continuous improvement suggestions to maintain flawless production outcomes.

Another major advantage of strong technical support is the ability to respond quickly to issues that arise unexpectedly. Even the most advanced production systems occasionally face challenges such as coating inconsistencies, assembly misalignment, or air leakage variations. A reliable support team can diagnose problems rapidly, implement corrective actions, and prevent disruptions in the supply chain. This responsiveness not only protects OEM production schedules but also reinforces customer confidence in the supplier’s capabilities. Technical support is also vital in the area of compliance and testing. Automotive lighting products must pass strict photometric, environmental, and safety tests before they can be approved for use. With advanced testing systems and engineering knowledge, Jinway helps OEM customers verify optical performance, structural integrity, and coating reliability. This ensures products meet international standards and perform safely on the road.

In the long term, strong technical support helps build trusted partnerships between suppliers and OEMs. It reduces total project cost, enhances product reliability, and speeds up time-to-market—factors that are critical in an industry driven by innovation and competition. For companies like Jinway, offering technical support is not just an added service; it is a core commitment that empowers customers to achieve successful, high-quality automotive lighting solutions.