The Role of Precision Tooling in Automotive Lighting Production

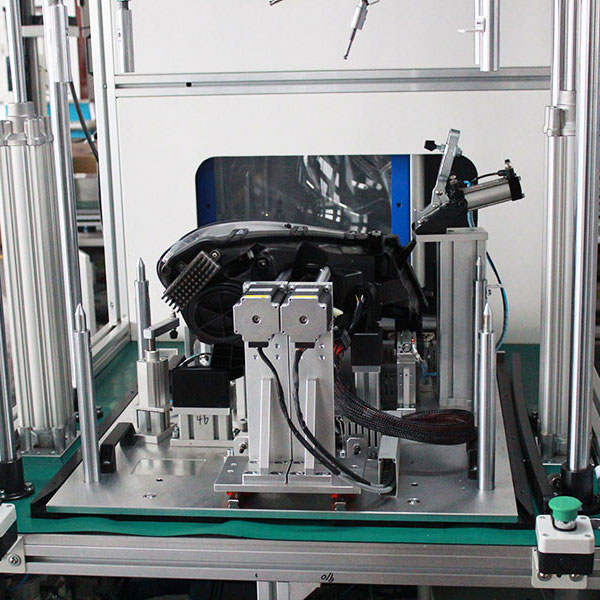

In automotive lighting production, precision is not optional—it is essential. As headlights and taillights evolve into highly engineered systems that integrate optics, electronics, and advanced materials, the accuracy of every component directly affects performance, safety, and appearance. At the foundation of this precision lies tooling. High-quality, precision tooling plays a decisive role in ensuring that automotive lighting components meet strict dimensional, functional, and aesthetic requirements. Automotive lighting components such as lenses, housings, reflectors, and internal brackets are manufactured with extremely tight tolerances. Even minor deviations in tooling can lead to misalignment, poor sealing, or inconsistent optical performance. Precision tooling ensures that each part is produced exactly as designed, allowing components to fit together seamlessly during assembly. This accuracy is especially critical for modern lighting systems that rely on precise beam patterns and controlled light distribution.

Tooling quality also has a direct impact on production efficiency. Well-designed and precisely manufactured molds enable stable, repeatable production with minimal variation. This reduces the need for frequent adjustments, lowers scrap rates, and shortens cycle times. In high-volume OEM automotive lighting production, these efficiencies translate into faster throughput and more reliable delivery schedules without compromising quality. Surface quality is another area where precision tooling plays a vital role. The finish of lighting components, particularly lenses and reflective surfaces, is heavily influenced by mold accuracy and surface treatment. High-precision tooling produces smooth surfaces that reduce the need for secondary finishing processes. This not only enhances visual appearance but also improves optical clarity and coating adhesion, supporting subsequent processes such as UV coating and anti-fog treatment.

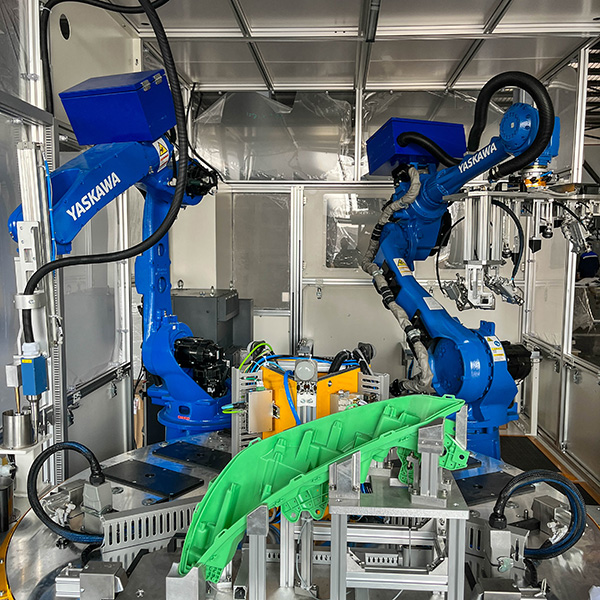

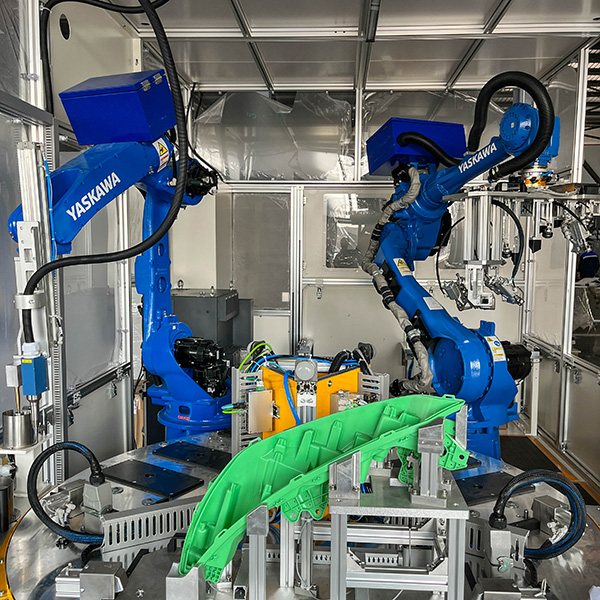

Precision tooling is also essential for ensuring effective sealing and long-term durability. Automotive lighting systems must be completely sealed to protect internal components from moisture, dust, and temperature fluctuations. Accurate tooling ensures consistent gasket grooves, bonding surfaces, and joint geometries, enabling reliable sealing during assembly. This directly contributes to improved resistance against condensation, air leakage, and environmental stress over the product’s lifetime. In addition, precision tooling supports the growing demand for complex and customized lighting designs. As automotive brands seek distinctive lighting signatures, tooling must accommodate intricate shapes, thin walls, and integrated functional features. Advanced tooling technologies make it possible to manufacture these complex geometries consistently and at scale, enabling innovation without sacrificing manufacturability.

From a quality control perspective, precision tooling simplifies inspection and testing. When parts are produced with high consistency, testing systems can operate more efficiently and accurately. This stability helps manufacturers achieve zero-defect goals by reducing variation and improving predictability across production batches. Ultimately, precision tooling is the backbone of successful automotive lighting production. It ensures dimensional accuracy, supports efficient assembly, enhances surface quality, and enables reliable long-term performance. As automotive lighting continues to advance toward greater complexity and higher standards, the importance of precision tooling will only increase. Manufacturers that invest in high-quality tooling are better positioned to deliver innovative, durable, and visually superior lighting solutions that meet the demanding expectations of today’s global automotive market.