The Science Behind Uniform UV Curing in High-Volume Lighting Production

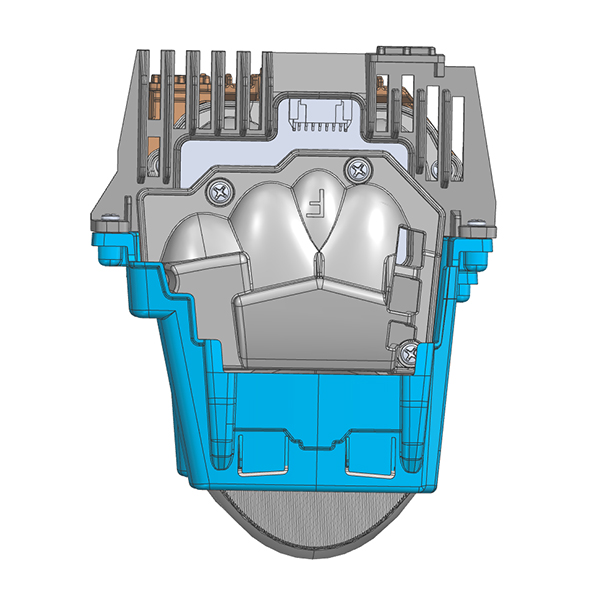

Uniform UV curing is a critical step in modern automotive lighting production, especially as LED modules, robust coatings, and decorative elements become increasingly essential to lamp performance and styling. At its core, UV curing transforms liquid coatings—whether protective layers, adhesives, or inks—into solid, durable films in a matter of seconds. But achieving truly uniform curing across thousands of components requires far more than just exposure to light. It demands science-driven process control, engineering accuracy, and deep knowledge of material behavior. The challenge begins with the chemistry of UV-curable coatings. These coatings contain photoinitiators—compounds that react instantly when exposed to wavelengths in the ultraviolet spectrum. Once activated, the molecules form long polymer chains, creating a strong, cross-linked surface. For the reaction to work fully, every part of the coated area must receive the right dose—measured in millijoules per square centimeter—of UV energy. Too little, and the coating remains tacky, undercured, or weak. Too much, and the same coating may become brittle, haze, or discolor over time.

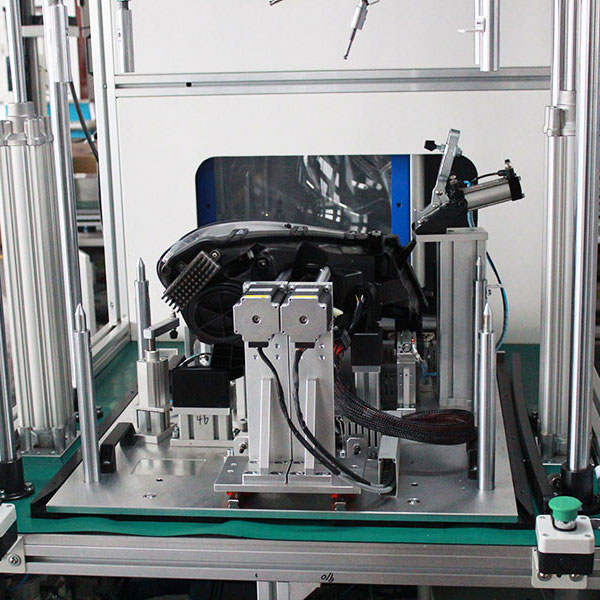

Consistency is essential for large-scale production lines that operate continuously. Parts move through conveyors at fixed speeds, and lamps vary in geometry from simple flat lenses to multi-surfaced reflectors. That introduces a unique difficulty—UV light does not cure uniformly on its own. Shadows, curves, and internal contours can create dead spots, leaving uncured pockets invisible to the naked eye. This is why UV curing systems are engineered with reflectors, multi-angle lamp arrays, and precise positioning to eliminate uneven exposure. Controlling wavelength is equally important. Different coating chemistries activate at different UV bands—typically UVA (around 365–405 nm), UVB, or UVC. The curing equipment must match the formulation exactly. High-intensity LED UV curing systems are becoming standard because they offer stable wavelength output and longer lamp lifespans than traditional mercury lamps. For automotive lighting, where coating performance affects weather resistance, optical clarity, and long-term yellowing, the match between chemistry and wavelength is non-negotiable.

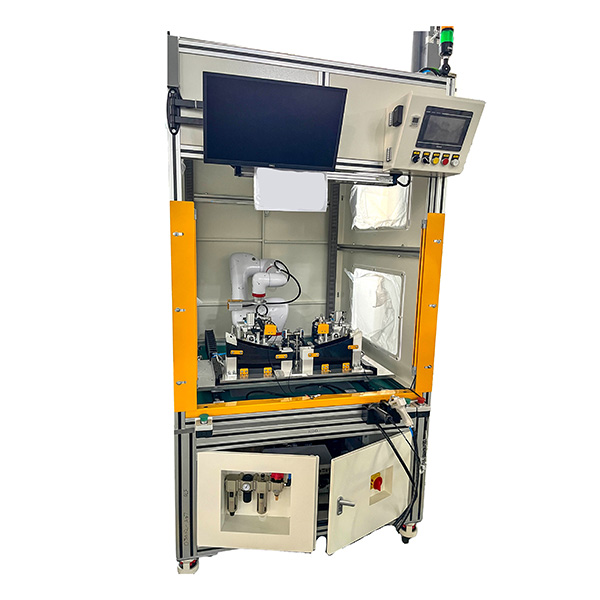

Thermal management is an often overlooked factor. Even though UV curing is fast, the energy absorbed can increase surface temperature. If not controlled, heat may warp plastic substrates, distort optical surfaces, or introduce stress into bonding layers. Uniform curing requires stable lamp temperature, efficient cooling systems, and controlled conveyor dwell time. A balanced thermal profile ensures that the coating cures fully without compromising material integrity beneath it. Another cornerstone of uniform UV curing is in-line measurement. Sensors monitor light intensity, lamp output, and real-time exposure levels. Because lamp performance can degrade gradually over time—even LED sources lose intensity—automotive plants calibrate curing equipment frequently. Some factories deploy closed-loop controls where sensors adjust intensity automatically to maintain target curing energy, ensuring that every job meets specification regardless of lamp age or environmental conditions.

Uniform curing also supports long-term durability in real-world vehicle environments. Automotive lighting faces UV sunlight, car wash chemicals, gravel spray, and constant vibration. A properly cured coating forms a complete polymer network that resists cracking, peeling, or moisture penetration. Uniformity ensures that no weak points exist—critical for preventing fogging, corrosion of metallic components, or delamination between lenses and housings. As production volumes continue to climb, high-speed curing systems allow higher throughput without sacrificing quality. Multi-lamp curing tunnels, rotational fixtures, and simultaneous dual-surface curing enable automotive suppliers to meet OEM demands for millions of parts per year with zero process variation. In many cases, UV curing integrates seamlessly with smart manufacturing technologies—barcode tracking, MES systems, and automated inspection—for a full digital quality history.

The future of uniform UV curing is moving toward even greater precision. AI-driven models can predict optimal lamp arrangement, robotic alignment ensures repeatable exposure paths, and smart coatings may one day self-adjust to curing energy variations. With electric vehicles driving new lighting designs—from light bars to signature patterns—the demand for perfect coating performance will only increase. Uniform UV curing is where chemistry, optics, engineering, and automation converge. By mastering the science behind it, manufacturers like Jinway deliver coatings that are not only visually flawless but engineered for long-life reliability on the road.