What Is Photometric Testing and Why Is It Critical in Headlamp Manufacturing?

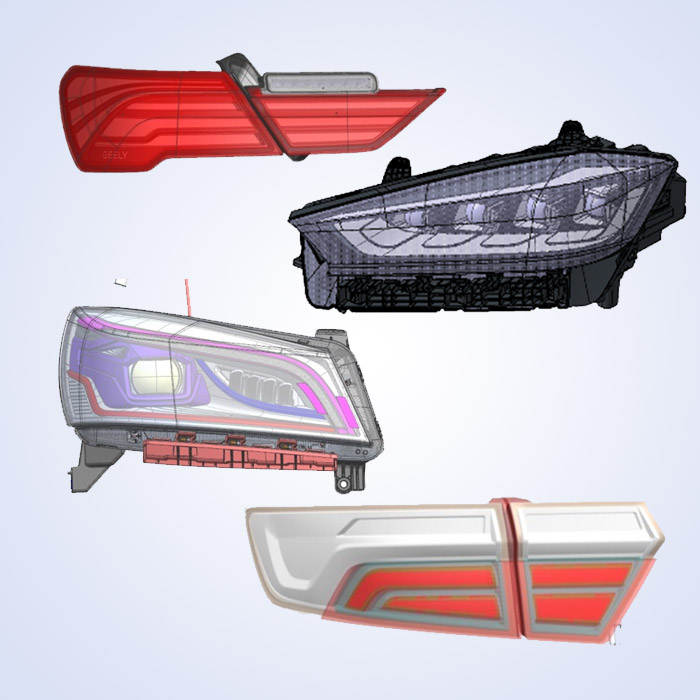

In the realm of automotive manufacturing, few components are as critical to safety and performance as the headlamp. As the primary source of visibility during nighttime driving or poor weather conditions, headlamps must function with absolute precision. One essential process that ensures this precision is photometric testing—a rigorous and highly technical evaluation that validates the performance of vehicle lighting systems.

At Jinway Technology Co., Ltd., we specialize in automated photometric optic test machines, helping headlamp manufacturers meet both regulatory requirements and consumer expectations.

What Is Photometric Testing?

Photometric testing is the process of measuring visible light emitted by a lighting device to determine its optical performance. In automotive applications, it’s primarily used to verify whether headlamps, taillights, fog lamps, and other lighting systems comply with international safety standards and deliver the required illumination for safe driving.

These tests assess:

Luminous intensity (candela): How much light is emitted in a particular direction

Illuminance (lux): How much light falls on a surface

Beam pattern and shape: Including the cutoff line, spread, and symmetry

Light color and chromaticity: Ensuring proper hue and temperature (e.g., white vs. blue light)

Uniformity: Avoiding bright spots or dark zones in the beam

Why Photometric Testing Is Crucial in Headlamp Manufacturing

1. Safety and Visibility

Headlamps must illuminate the road without dazzling other drivers. A poorly aligned beam, excessive brightness, or inadequate spread can lead to accidents, legal liability, or failures in regulatory inspection. Photometric testing ensures each headlamp delivers optimal light output while staying within glare limits.

2. Regulatory Compliance

Countries and regions enforce strict lighting regulations, such as:

ECE Regulation 112 / 123 (Europe)

SAE and FMVSS 108 (United States)

CCC (China Compulsory Certification)

Manufacturers must pass photometric tests to gain approval for vehicle sale in these markets. Failure to comply may lead to fines, recalls, or bans from entering certain regions.

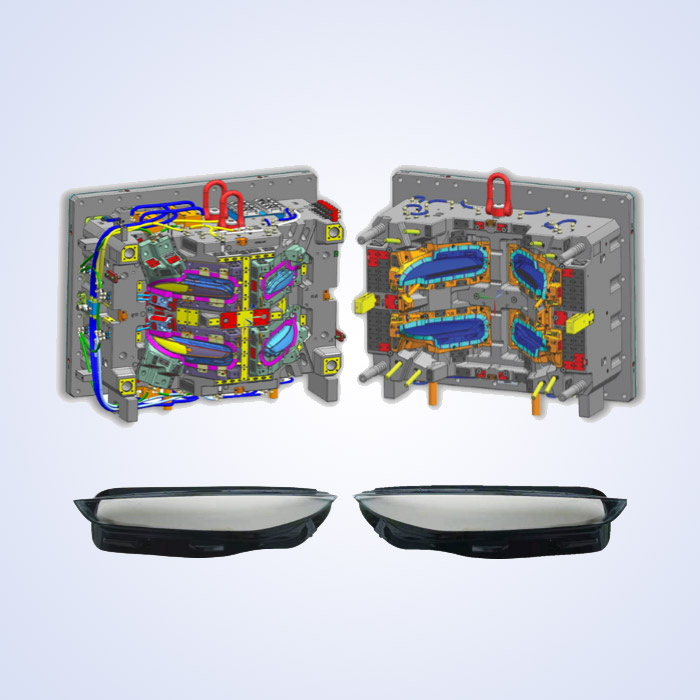

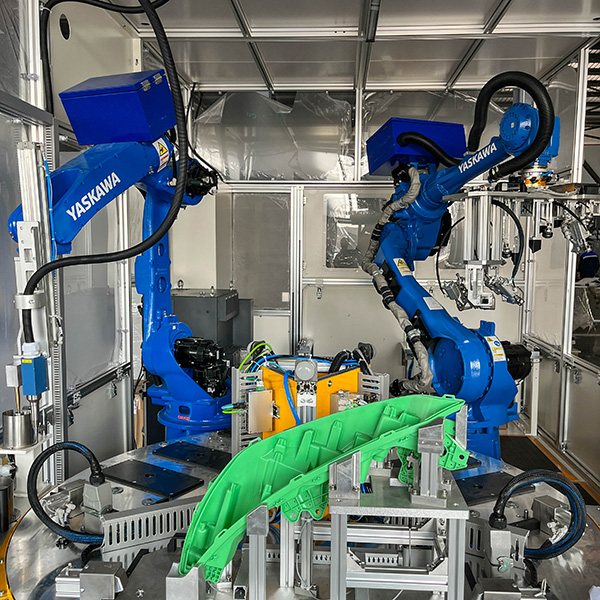

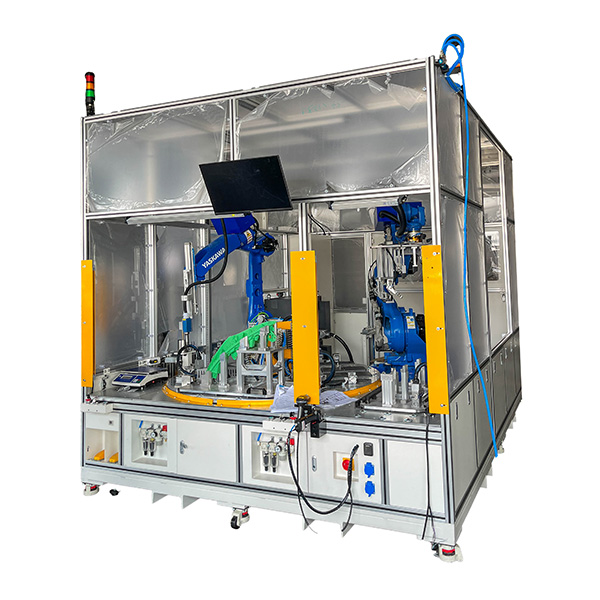

3. Consistency in Mass Production

In high-volume manufacturing, product variation is inevitable. Photometric testing provides automated quality control, ensuring each unit meets the same standard. At Jinway Technology, we integrate our test machines into automated production lines, providing real-time validation for every single lamp.

4. Support for Advanced Lighting Systems

Modern vehicles increasingly feature LED, matrix beam, and adaptive headlamp systems, which require complex, multi-zone testing. Photometric testing can measure different lighting modes—high beam, low beam, daytime running lights (DRLs)—and simulate on-road scenarios to validate smart lighting behavior.

How Photometric Testing Works: The Process Explained

Step 1: Test Setup and Positioning

The lamp is mounted at a fixed distance from a photometric sensor or imaging system, often in a dark room or enclosed chamber to eliminate ambient light.

Step 2: Light Activation

Different lighting functions are triggered (e.g., low beam, high beam), either manually or via automated PLC control.

Step 3: Data Acquisition

Sensors measure light output across various angles and locations. Some systems use goniophotometers or imaging photometers to capture the beam shape and intensity in real time.

Step 4: Evaluation and Comparison

The measured data is compared against regulatory and OEM specifications. Beam alignment, intensity, color, and cutoff accuracy are evaluated.

Step 5: Result Generation

Pass/fail results are logged, and defective units are flagged for rework. At Jinway, this process is automated and integrated with MES/ERP systems for traceability and audit readiness.

Jinway Technology’s Role in Photometric Testing

At Jinway Technology Co., Ltd., we design and manufacture intelligent photometric optic test machines tailored to the needs of modern automotive lighting production. Our systems offer:

Fast cycle times for in-line testing

Multi-function testing (low/high beam, DRL, position lamps)

Precision sensors and optics for high accuracy

Data storage and report generation

Compatibility with global standards (ECE, SAE, DOT, etc.)

Custom integration with headlamp assembly lines and final inspection stations

Our test machines are trusted by major automotive lighting brands and have been deployed in production environments across Asia, Europe, and North America.

Conclusion: Quality You Can See

In headlamp manufacturing, photometric testing isn’t optional—it’s critical. It ensures your product meets legal requirements, functions safely, and upholds your brand’s reputation. With vehicle lighting technology advancing rapidly, robust photometric testing has never been more important.

At Jinway Technology, we help manufacturers automate and elevate this essential process, delivering reliability and precision at scale. If you’re looking to optimize your headlamp production with integrated photometric testing, we’re ready to support you every step of the way.