Why Photometric Optic Test Machines Are Critical for Headlamp Approval

Headlamp approval is one of the most critical stages in automotive lighting development, as it determines whether a vehicle can legally enter a market. Beyond design aesthetics and brightness, regulators focus on how light is distributed on the road and how it affects other drivers. Photometric optic test machines are essential tools in this process, providing precise, repeatable measurements that verify whether a headlamp meets strict regulatory requirements. Photometric testing evaluates key optical parameters such as luminous intensity, beam pattern, cutoff sharpness, and glare control. These characteristics directly impact road visibility and driving safety. A headlamp that appears bright to the naked eye may still fail approval if its beam is uneven, poorly focused, or produces excessive glare. Photometric optic test machines capture these details with high accuracy, removing subjectivity from the evaluation process.

Global automotive regulations define specific photometric criteria that must be met. Standards such as ECE in Europe, SAE and FMVSS in North America, and GB regulations in China specify allowable intensity levels at precise angles and distances. Photometric test machines are designed to simulate these regulatory conditions, measuring light output across a defined grid and generating data that can be directly compared against approval limits. During product development, photometric testing plays a crucial role in design optimization. Engineers use test results to refine projector lenses, reflectors, and light source positioning. Small adjustments based on accurate data can significantly improve beam quality and compliance margins. Without reliable photometric testing, design iterations would rely on trial and error, increasing development time and cost.

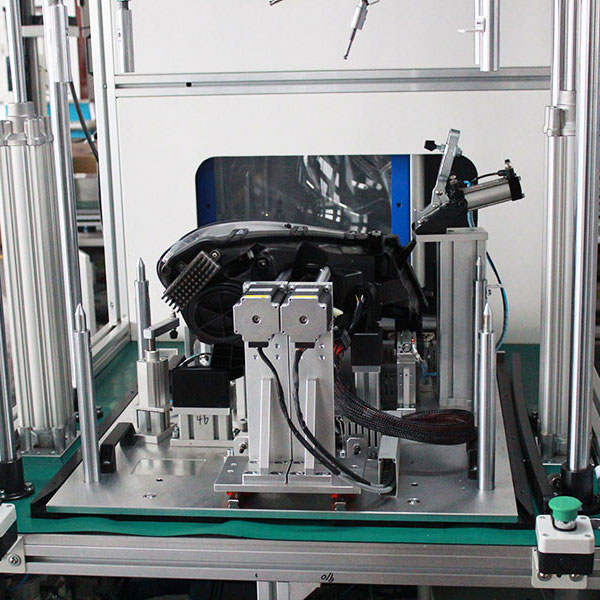

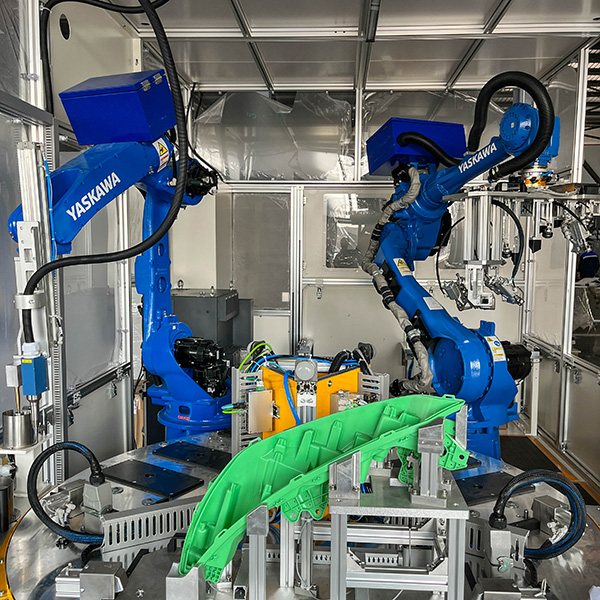

In mass production, photometric optic test machines ensure consistency from unit to unit. Even with precision tooling and automated assembly, minor variations can occur. In-line or end-of-line photometric testing identifies deviations early, preventing non-compliant products from reaching the market. This protects manufacturers from costly recalls, rework, and reputational damage. Photometric testing is also essential for verifying the performance of advanced lighting technologies. LED, matrix, and adaptive headlamp systems require precise optical control to function correctly. Photometric machines can assess dynamic beam patterns and complex light distributions, ensuring these advanced systems meet both functional and regulatory expectations.

Another important aspect is traceability and documentation. Approval authorities and OEM customers often require detailed photometric reports as part of the certification process. Photometric optic test machines generate standardized data sets and visual maps that provide clear evidence of compliance. These records support audits, homologation processes, and ongoing quality assurance. Environmental factors further highlight the importance of photometric testing. Temperature changes, aging, and component wear can affect light output over time. By incorporating photometric testing into validation and endurance testing, manufacturers can confirm that headlamps remain compliant throughout their expected lifespan, not just when new.

Ultimately, photometric optic test machines are critical because they bridge the gap between engineering intent and regulatory reality. They transform complex lighting performance into measurable, verifiable data that ensures safety, compliance, and market access. In a highly regulated industry, reliable photometric testing is not optional—it is the foundation of successful headlamp approval and global automotive lighting excellence.