Why UV Coating Lines Are Essential for High-Performance Automotive Headlamps

In the rapidly advancing world of automotive technology, the performance of lighting systems—particularly headlamps—has become a crucial factor in vehicle design and safety. One of the most critical advancements in automotive lighting technology is the use of UV coating lines for enhancing the durability and performance of headlamp lenses. This innovative process, known as UV light curing coating, plays a pivotal role in meeting the increasing demands for higher performance and longer-lasting automotive headlamps. Here’s why UV coating lines are an essential part of high-performance automotive headlamp production.

1. Enhancing Durability and Scratch Resistance

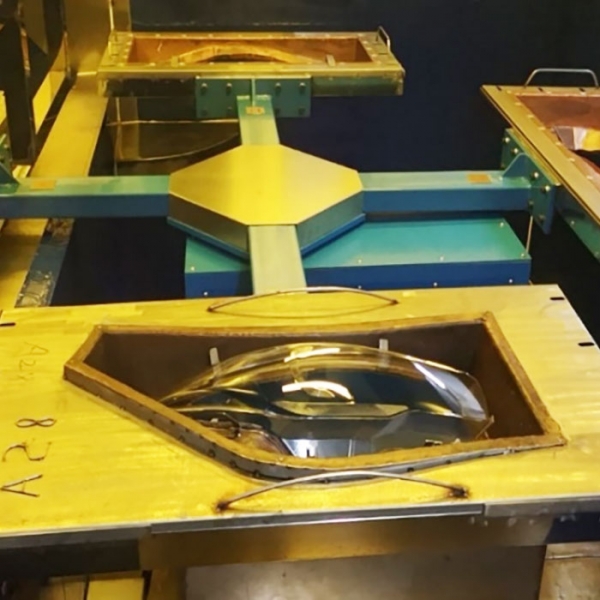

Automotive headlamps are exposed to a wide variety of environmental factors, including extreme temperatures, harsh weather conditions, UV rays, road debris, and even dirt and dust. These elements can cause damage to the lens surface, leading to scratches, yellowing, and clouding over time, which significantly reduces the performance and clarity of the headlights.

Polycarbonate (PC), a commonly used material for automotive lenses, is relatively soft compared to other plastics. As a non-crystalline plastic, it lacks the hardness required to withstand harsh conditions and impacts. To address this issue, UV coating is applied to PC lenses, providing a hard, protective layer that increases surface hardness, ensuring the lens remains clear and resistant to scratches. UV coatings, specifically those with a pencil hardness rating of 2H, ensure that the lens can endure the impact of road debris, sand, and other environmental challenges without losing its optical quality.

2. Improved Optical Clarity and Light Transmittance

Headlamp lenses must offer high levels of optical clarity to ensure proper light distribution on the road. The ability of the lens to transmit light efficiently is paramount, especially at night or during poor visibility conditions. UV coating not only strengthens the surface but also enhances the light transmittance of the lens. For automotive lighting, it is essential that the lens maintains a transmittance rate of 85% or higher to ensure optimal visibility and safety for drivers.

The UV coating process helps maintain the lens’s optical clarity by protecting it from yellowing or hazing caused by UV exposure and other environmental factors. This means the headlamp can provide consistent, bright illumination over its entire lifespan, ensuring that drivers are not compromised by cloudy or dimmed lights.

3. Protection Against UV Radiation

As headlamps are exposed to direct sunlight, their lenses are at risk of degradation due to prolonged UV radiation. Without adequate protection, the lens material can deteriorate, leading to fading, cracking, and a reduction in light transmission. UV coating lines protect the headlamp lenses from this degradation by applying a layer that blocks harmful UV rays, thereby preserving the lens material and extending its lifespan.

In addition to protecting the polycarbonate lens from UV radiation, the UV coating also prevents the lens from becoming brittle over time, a common issue when materials are exposed to sunlight and heat. This long-term protection is crucial for maintaining the performance and appearance of the headlamp throughout its use.

4. Temperature Resistance and High-Performance Standards

Automotive headlamps, especially those designed for high-performance vehicles, are subjected to extreme temperature fluctuations. When a vehicle is traveling at high speeds, the friction between the vehicle and air causes the temperature of the headlamp surface to rise significantly. In some cases, the temperature of the headlamp surface can reach 90-100°C.

Given the high temperatures, the headlamp lens material needs to be able to withstand thermal stress without losing structural integrity. UV coating provides a temperature-resistant barrier, ensuring that the polycarbonate lenses can maintain their shape and strength, even under extreme conditions. This resistance is critical for the long-term performance of headlamps, especially in high-performance and luxury vehicles that require reliable lighting under all conditions.

5. Cost-Effectiveness and Efficiency

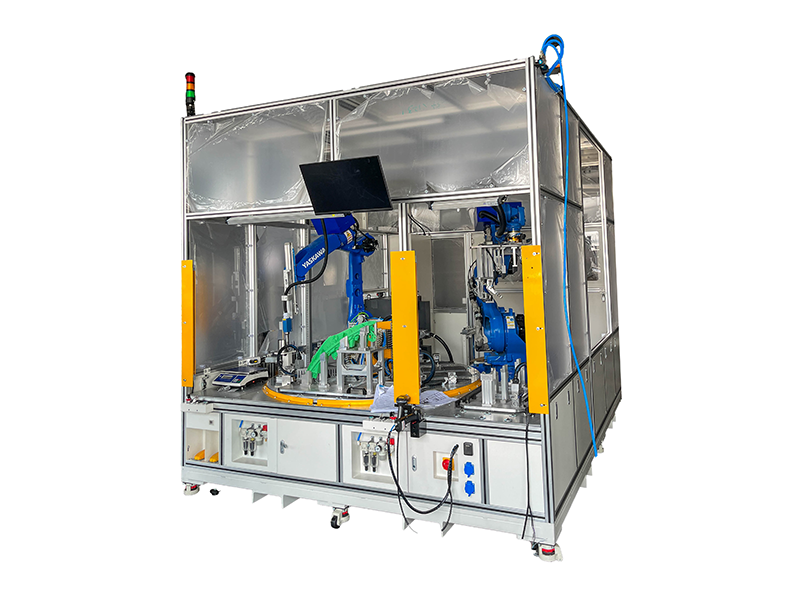

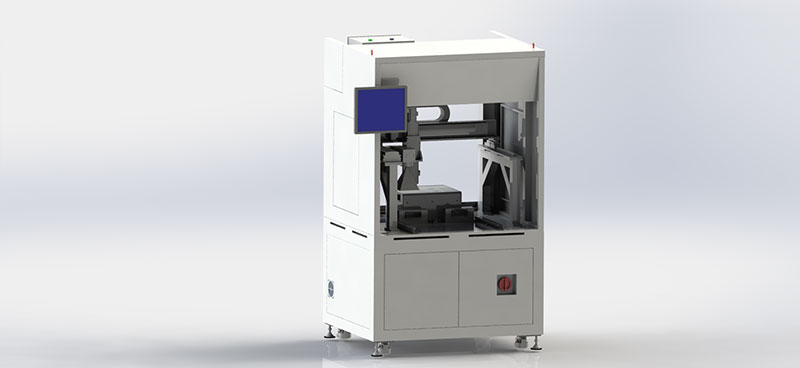

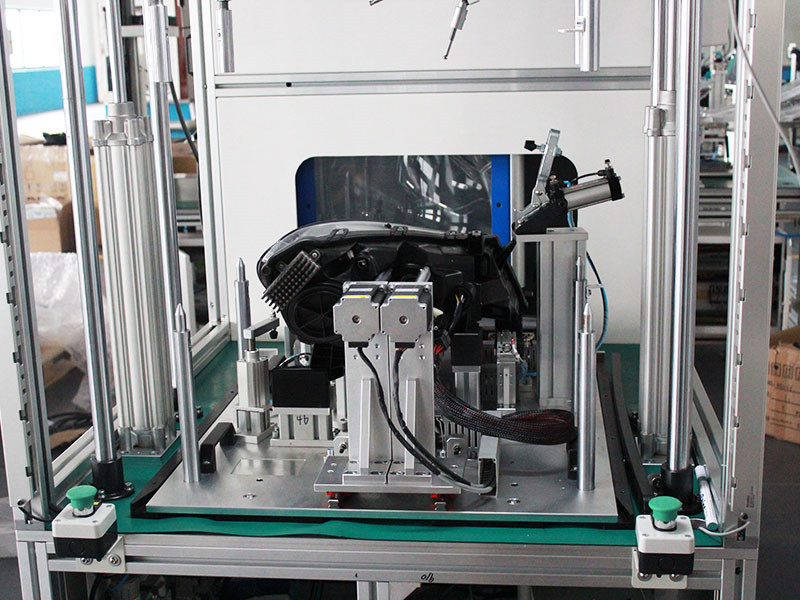

From a manufacturing perspective, UV coating lines offer several benefits, including improved efficiency, cost-effectiveness, and ease of application. The UV coating process is fast, allowing for high-volume production without compromising on quality. It eliminates the need for additional layers of protective coatings, which can add time and cost to the production process.

The UV light curing technology used in these lines also allows for the rapid curing of the coating, reducing production time and energy consumption. This makes UV coating an ideal solution for manufacturers who need to maintain high production rates while ensuring that each headlamp meets the required performance and durability standards.

6. Meeting Automotive Industry Standards

The automotive industry is governed by strict safety and quality standards that require headlamp lenses to meet specific performance benchmarks. These standards include durability, light transmittance, impact resistance, and resistance to environmental factors like UV radiation and temperature fluctuations. UV coating lines help manufacturers meet these rigorous standards, ensuring that their headlamp lenses perform optimally throughout their lifespan.

By providing a hard, protective layer, UV coatings help meet or exceed the minimum requirements for hardness, light transmittance, and environmental protection set by automotive regulatory bodies. This ensures that automotive manufacturers can produce headlamps that are safe, efficient, and compliant with industry regulations.

Conclusion: The Essential Role of UV Coating Lines in Automotive Lighting

In conclusion, UV coating lines are a critical component in the production of high-performance automotive headlamps. They enhance the durability, optical clarity, temperature resistance, and UV protection of polycarbonate lenses, ensuring that headlamps deliver optimal performance over the long term. With the ability to withstand harsh environmental conditions, maintain high light transmittance, and meet industry standards, UV coating is an indispensable technology for the automotive lighting sector.

As vehicles continue to evolve with smarter designs and higher performance requirements, the role of UV coating lines in automotive manufacturing will only grow more significant, providing a foundation for safer, more reliable, and longer-lasting automotive lighting solutions.