Zero-Defect Manufacturing: Building a Process That Catches Every Error Before It Leaves the Factory

In manufacturing, the cost of errors extends far beyond the factory floor. A single defective component can lead to warranty claims, recalls, and damage to a brand’s reputation. To combat this, leading manufacturers are adopting a philosophy known as zero-defect manufacturing, where the objective is not just reducing errors but eliminating them entirely. At Jinway Technology Co., Ltd., we develop automation and testing solutions that make zero-defect production possible by detecting and correcting problems in real time, before they ever reach customers.

Defining Zero-Defect Manufacturing

Zero-defect manufacturing is not about perfection in theory—it is about creating processes where mistakes are systematically prevented or corrected before they affect the final product. Instead of relying solely on post-production inspections, this approach embeds quality control directly into the manufacturing process. Every step of production is monitored, measured, and validated against established parameters to ensure that deviations are detected immediately. This way, defective products never move downstream, and the factory output remains consistently reliable.

The Role of In-Line Testing

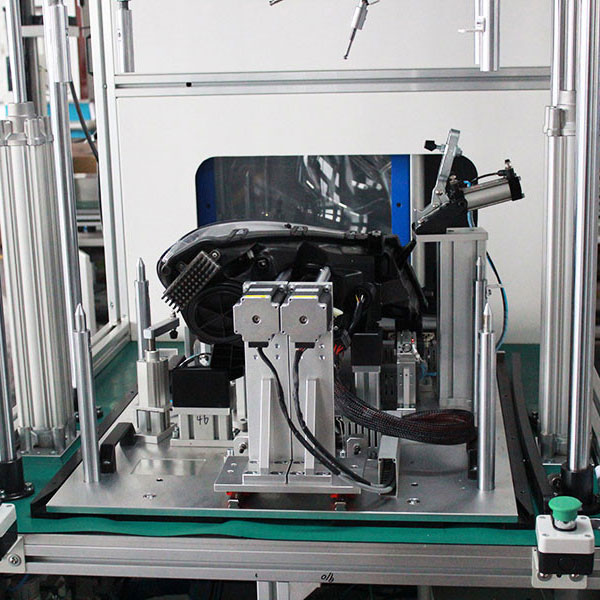

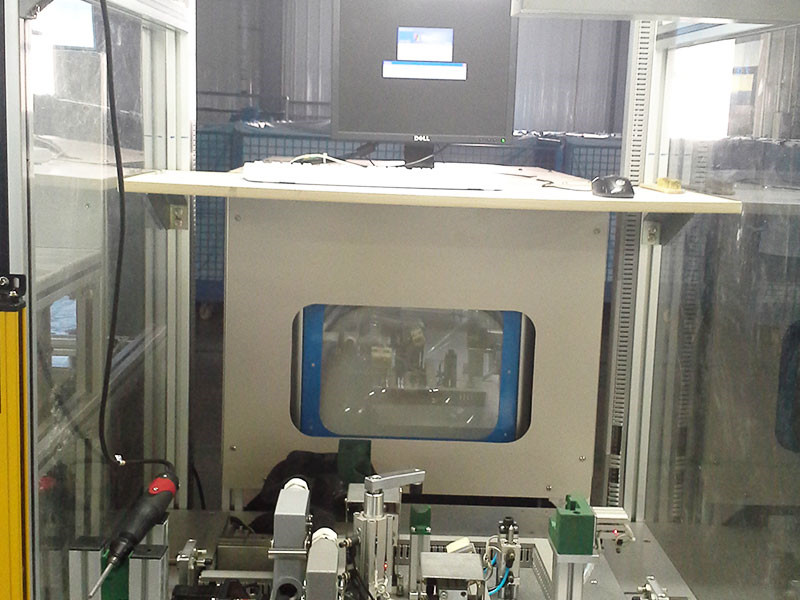

One of the pillars of zero-defect manufacturing is in-line testing, where products are continuously inspected during production rather than after completion. In optical and photometric testing, for example, sensors measure light intensity, beam shape, and alignment for each unit as it is produced. If a component fails to meet standards, the system identifies it instantly, allowing the defect to be corrected before it becomes part of the final assembly. This proactive approach not only reduces waste but also ensures compliance with regulatory requirements.

Real-Time Feedback and Self-Correction

Real-time feedback loops are essential to achieving zero defects. As systems monitor performance, they compare results against precise benchmarks. If they detect a deviation, they automatically adjust parameters such as alignment, pressure, or illumination to bring the process back into specification. This self-correcting ability minimizes reliance on manual intervention and ensures that small errors never accumulate into larger quality problems.

Benefits of Zero-Defect Manufacturing

The benefits of building a zero-defect process are substantial. First, it reduces rework and scrap, lowering material costs. Second, it increases customer satisfaction by delivering products that consistently meet or exceed expectations. Third, it strengthens compliance with safety and regulatory standards, particularly in industries like automotive, aerospace, and electronics where tolerances are extremely strict. Over time, the savings in avoided warranty claims and reputation damage far outweigh the investments in advanced testing and automation.

Application in Automotive Lighting

In the automotive industry, where Jinway Technology Co., Ltd. plays a significant role, zero-defect principles are especially critical. Automotive lighting components such as headlamps, taillamps, and indicators must meet exacting photometric standards. Even a minor deviation in light distribution can compromise driver visibility and safety. By embedding optical testing systems directly into the assembly line, we ensure that every lamp is tested for compliance. This prevents defective parts from leaving the factory and guarantees that customers receive products of the highest reliability.

Data-Driven Process Control

Zero-defect manufacturing relies heavily on data. Modern systems collect and analyze thousands of data points in real time, covering aspects such as alignment accuracy, optical output, temperature stability, and vibration tolerance. This data not only helps correct issues immediately but also builds a knowledge base for future optimization. By identifying patterns and root causes of recurring issues, manufacturers can redesign processes to eliminate problems at their source.

Overcoming Implementation Challenges

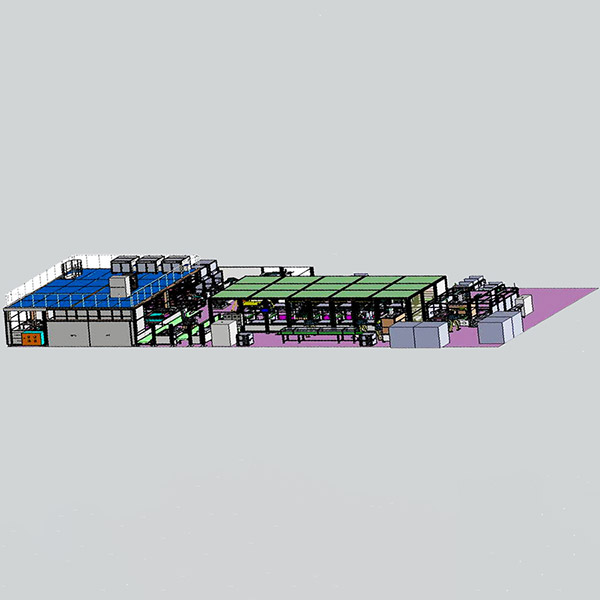

Building a zero-defect process is not without its challenges. It requires investment in advanced automation, optical inspection systems, and software capable of real-time data analysis. Additionally, it demands a cultural shift within the factory, where quality becomes the responsibility of every process, not just the final inspection team. At Jinway, we help our clients overcome these challenges by designing modular solutions that can integrate with existing systems, allowing factories to move toward zero-defect manufacturing step by step.

The Future of Zero-Defect Manufacturing

As manufacturing evolves, technologies like artificial intelligence, machine learning, and digital twins will push zero-defect principles even further. Predictive analytics will allow systems to forecast potential defects before they happen, while simulations will test process changes virtually before they are applied on the factory floor. These advancements will make it possible to achieve even higher levels of reliability while reducing costs and improving sustainability.

Conclusion

Zero-defect manufacturing represents the future of industrial production, where errors are not merely reduced but prevented entirely. By embedding in-line testing, real-time feedback, and data-driven process control, factories can ensure that every product leaving the floor meets the highest standards of quality. At Jinway Technology Co., Ltd., we are proud to play a role in this transformation by delivering automation and testing solutions that help manufacturers achieve true zero-defect performance, protecting their reputation and ensuring long-term success.